Novel method for preparing trisilylamine

A new type of trisilylamine technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of reducing the yield of trisilylamine, and achieve the goal of reducing production cost, improving utilization rate, and increasing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

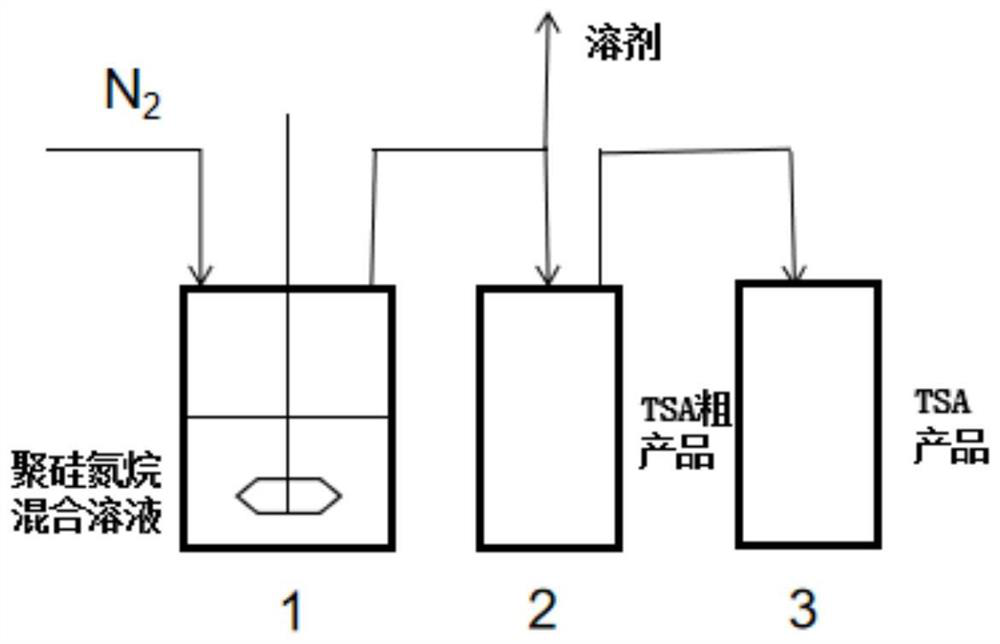

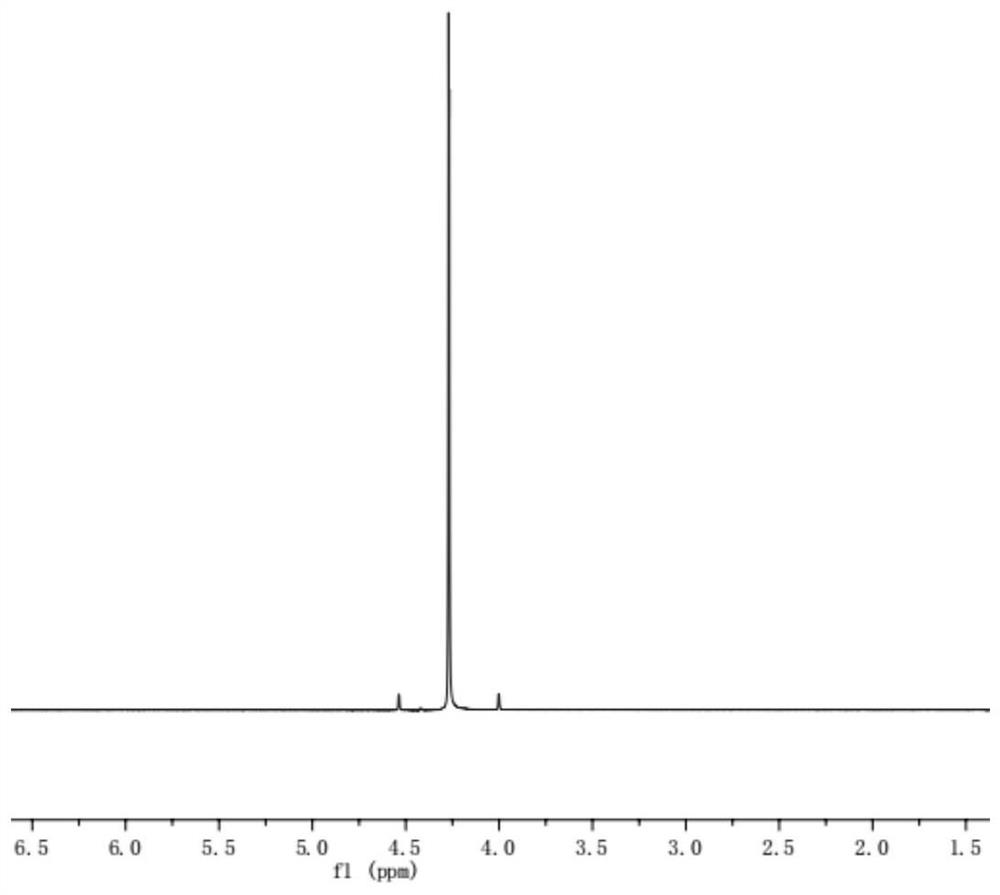

[0035] 5g of polysilazane and n-hexane solvent were mixed into a 5wt% mixed solution, transferred to a high-temperature and high-pressure reactor, and the solvent was distilled off under reduced pressure under an inert atmosphere of nitrogen, and then heated to 350°C for pyrolysis, and The pyrolyzed gas was condensed and recovered in the flask, and the collected liquid was heated and distilled to obtain the TSA product, which was detected by gas chromatography. The crude product of TSA was 1.55 g, the product purity was 97.5%, and the product yield was 31%.

Embodiment 2

[0037] 5g of polysilazane and n-hexane solvent were proportioned into a mixed solution of 5wt%, transferred to a high-temperature and high-pressure reactor, and the solvent was distilled off under reduced pressure under an inert atmosphere of nitrogen, and then heated to 400°C for pyrolysis, and The pyrolyzed gas was condensed and recovered in the flask, and the collected liquid was heated and distilled to obtain the TSA product, which was detected by gas chromatography. The crude product of TSA was 1.95 g, the product purity was 97.4%, and the product yield was 34%.

Embodiment 3

[0039] 5g of polysilazane and n-hexane solvent were mixed into a 5wt% mixed solution, transferred to a high-temperature and high-pressure reactor, and the solvent was distilled off under reduced pressure under an inert atmosphere of nitrogen, and then heated to 450°C for pyrolysis, and The pyrolyzed gas was condensed and recovered in the flask, and the collected liquid was heated and distilled to obtain the TSA product, and detected by gas chromatography, the crude product of TSA was 1.70 g, the product purity was 97.7%, and the product yield was 39%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap