Curve mechanism for roller shutter door

A rolling door and curve technology, which is applied in the field of rolling doors, can solve the problems of high cost, waste of materials, and unsightly appearance, and achieve the effect of small construction difficulty and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

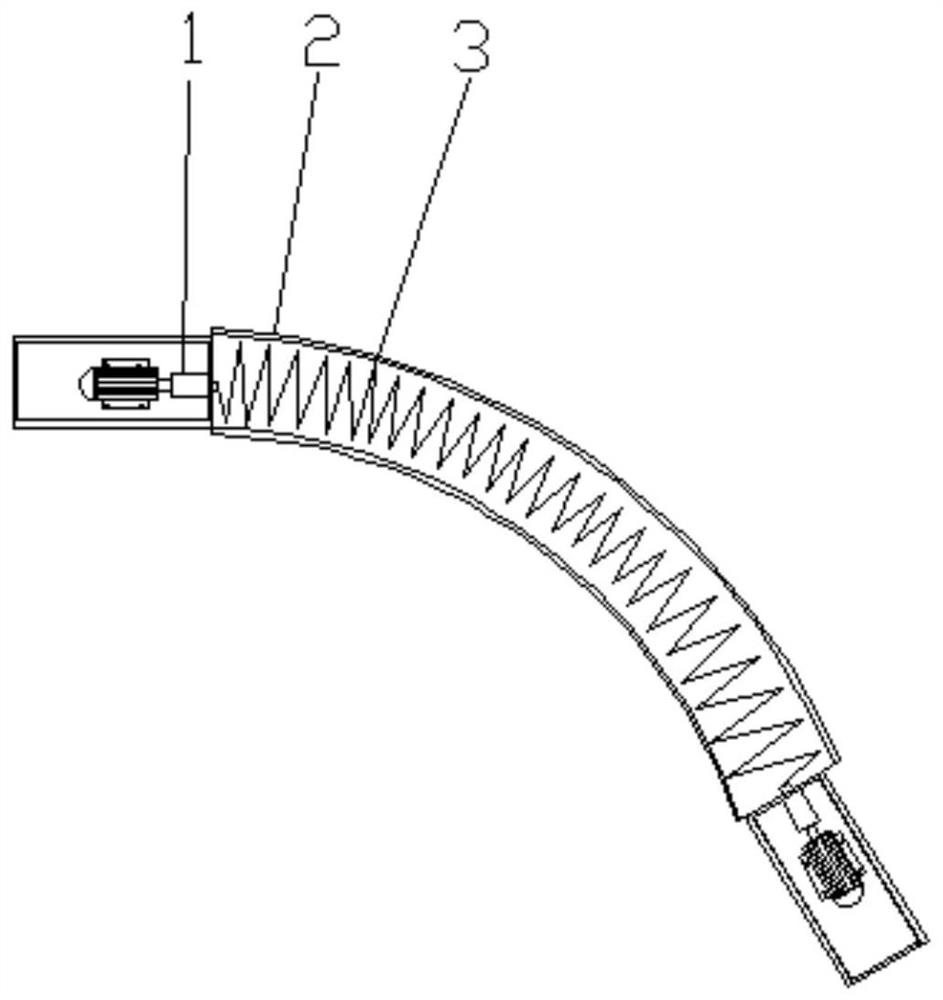

[0027] Such as figure 1 and Figure 5 As shown, a curved mechanism for a rolling shutter door includes two transmission shafts 1, a spiral tube or metal hose 2 is arranged between the two transmission shafts 1, and a spiral tube or metal hose 2 is provided inside Spring 3, one end of the spring 3 is connected with one of the transmission shafts 1, and the other end of the spring 3 is connected with the transmission shaft 1; the rotation of the two transmission shafts 1 drives the rotation of the spring 3, and the spring 3 Connected with the roller blind, the rotation of the spring 3 drives the roller blind at the curve to curl around the spring 3 or lower it.

[0028] Preferably, the diameter of the spring 3 increases from the middle to both ends, and the diameter of the spring 3 is smaller in the middle and larger in diameter at the two ends, which can be used to accommodate the curled roller blind.

[0029] Preferably, the spiral tube and the metal hose 2 are provided with...

Embodiment 2

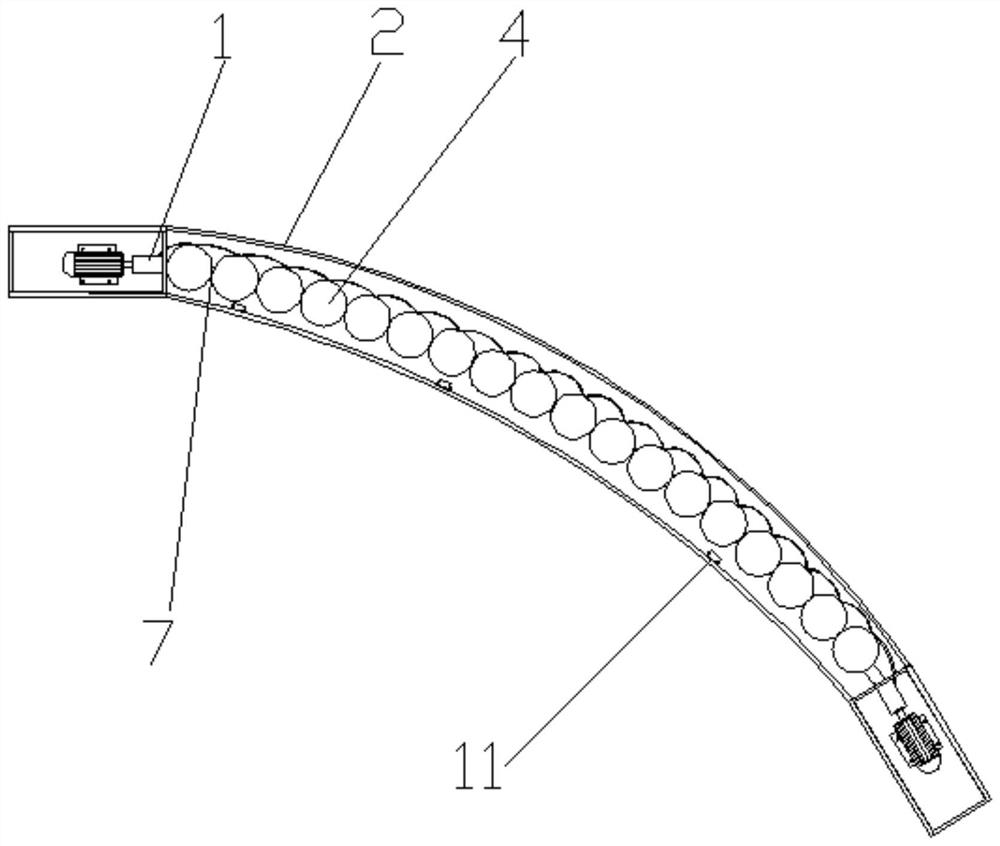

[0034] Such as figure 2 As shown, a curved mechanism for rolling shutter doors includes two transmission shafts 1, a spiral tube or metal hose 2 is arranged between the two transmission shafts 1, and a spiral tube or metal hose 2 is provided inside A plurality of balls 4, the plurality of balls 4 are connected in series through a steel wire rope 7, the two ends of the steel wire rope 7 are respectively hinged to one end of one of the transmission shafts 1, and the rotation of the two transmission shafts 1 drives the roller blind connected to the transmission shaft 1 to rotate, The roller blind drives a plurality of balls 4 to rotate, and the roller blind curls on the outer rings of the plurality of balls 4 or descends from the plurality of balls 4 .

[0035] Preferably, the spiral tube and the metal hose 2 are provided with openings, the openings are provided with reinforcing ribs 10, and the spiral tube or the metal hose 2 is used to accommodate the roller blind wound on the...

Embodiment 3

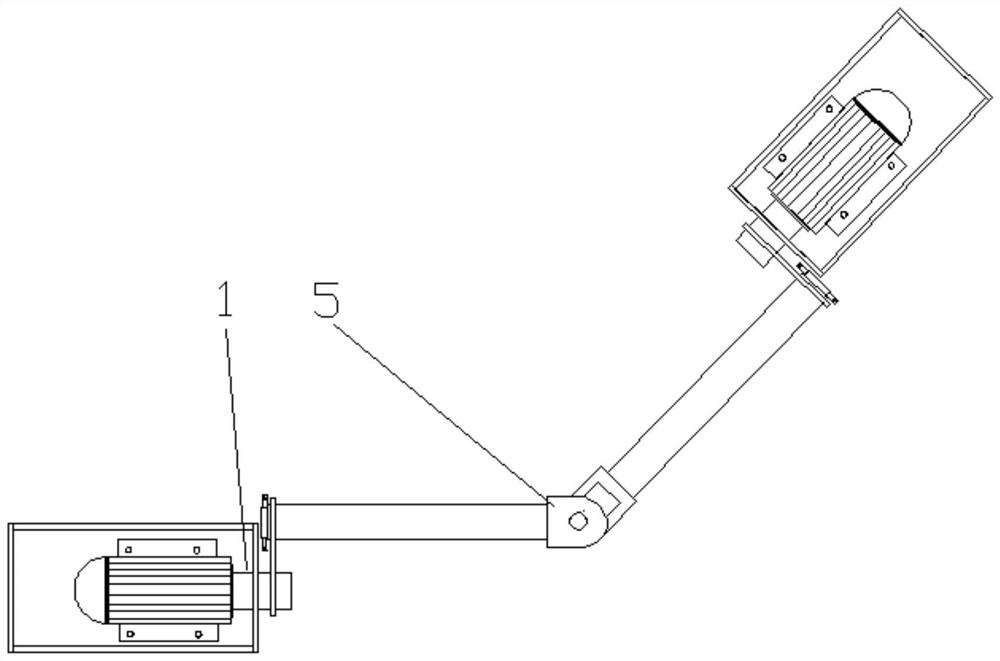

[0040] Such as image 3 As shown, a curved mechanism for rolling shutter doors includes two transmission shafts 1, a spiral tube or metal hose 2 is arranged between the two transmission shafts 1, and a spiral tube or metal hose 2 is provided inside A plurality of universal joints 5, the plurality of universal joints 5 are connected in sequence, and the adjacent universal joints 5 are connected through an intermediate shaft, and the universal joints 5 at both ends are connected to one of the transmission shafts 1 Fixed connection.

[0041] Further, the diameter of the intermediate shaft increases from the middle to both ends for accommodating the cord.

[0042] Further, a gap is provided between the metal hose 2 or the spiral tube and the universal joint 5 for accommodating the roller blind.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap