Pressure sensor

A pressure sensor and pressure technology, applied in the direction of measuring fluid pressure, instruments, fluid pressure measurement using capacitance changes, etc., can solve problems such as stick-slip, affecting pressure measurement accuracy, and different degrees of expansion, so as to eliminate relative displacement and reduce Difficulty of processing, effect of homogenization of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solution of the present invention, the pressure sensor provided by the present invention will be described in detail below with reference to the accompanying drawings.

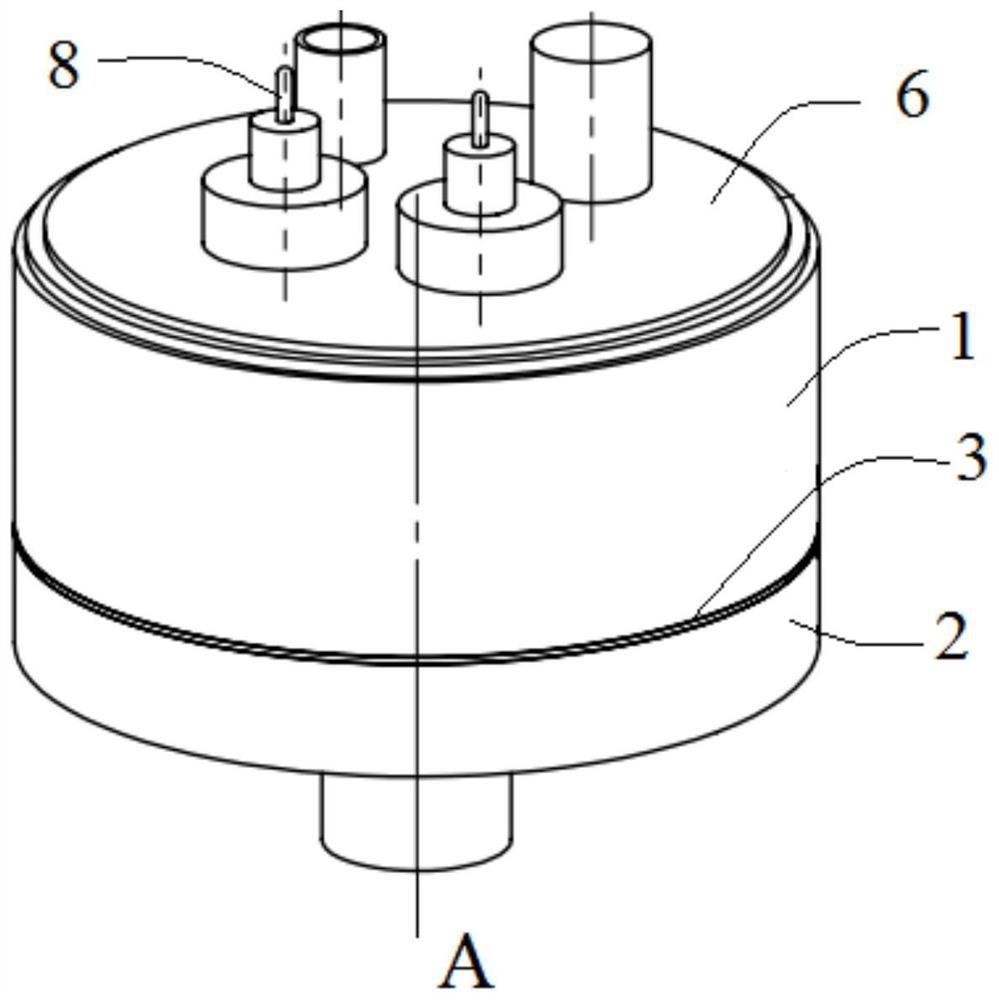

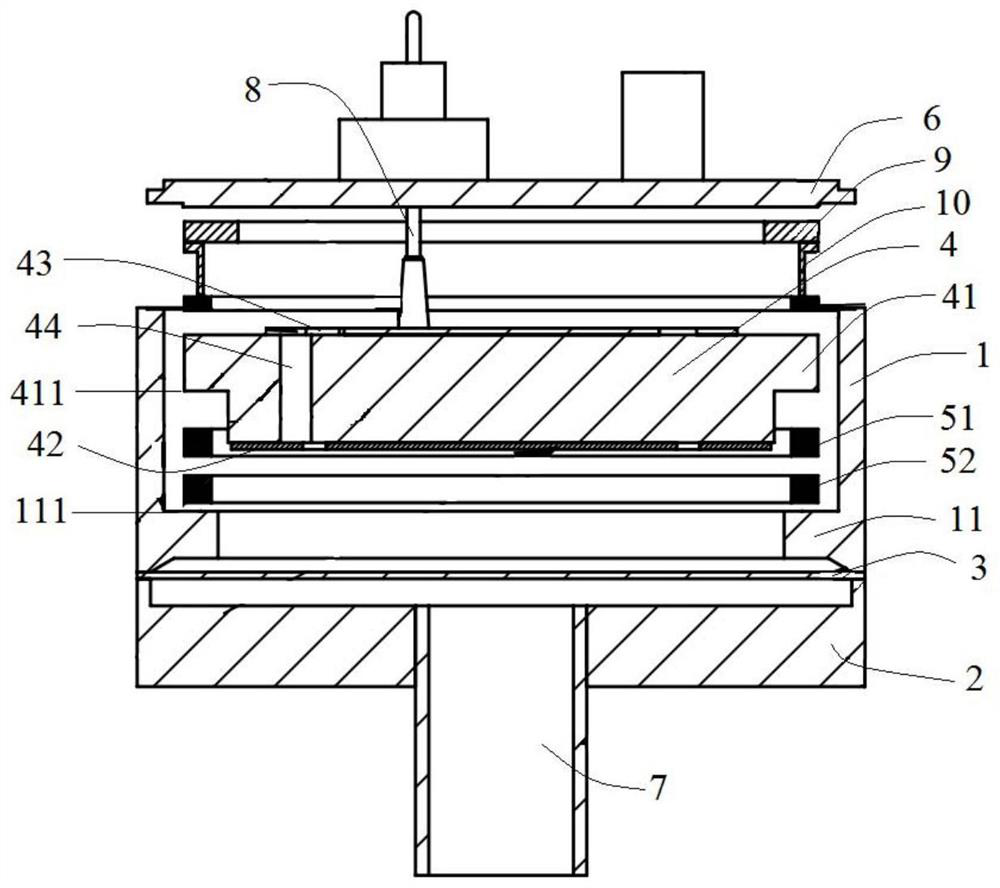

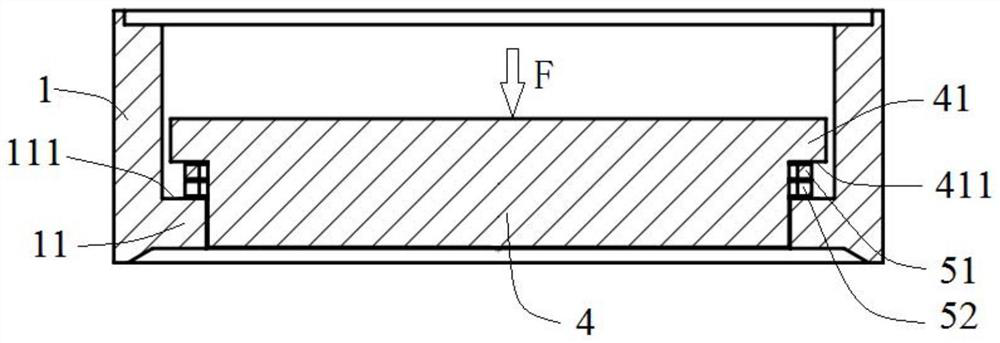

[0031] Please also refer to figure 1 and figure 2 , the pressure sensor provided by the embodiment of the present invention includes a first support 1, a second support 2, a moving membrane 3, an electrode part 4, two adjustment parts (51, 52), a top cover 6, a pipeline 7, Wire 8, elastic member 9 and support ring 10. Among them, the first support 1, the moving film 3 and the second support 2 are along the figure 1 The axis A of the medium pressure sensor is arranged sequentially from top to bottom, and all three are made of conductive metal materials, and are connected together by means of welding or the like. And, the top of the first support 1 is provided with a top cover 6, in order to seal the top opening of the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com