Backlight module and display device

A backlight module and display panel technology, which is applied in the directions of identification devices, optics, nonlinear optics, etc., can solve problems such as poor display effect, loose optical film layer, warping deformation, etc., to avoid warping and deformation of the diaphragm, and solve Shadows, effects that enhance the display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

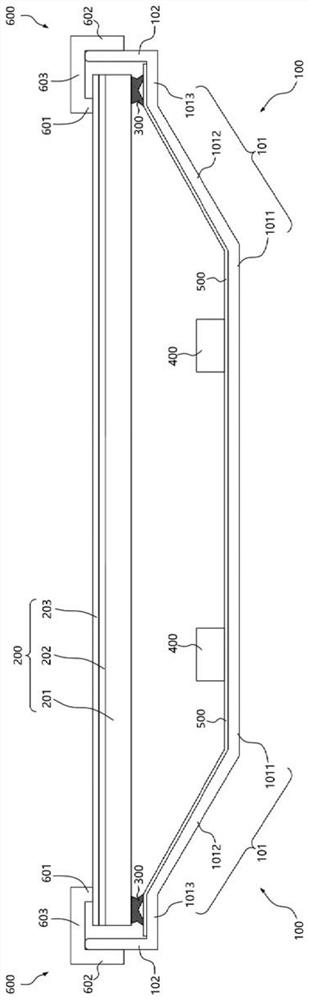

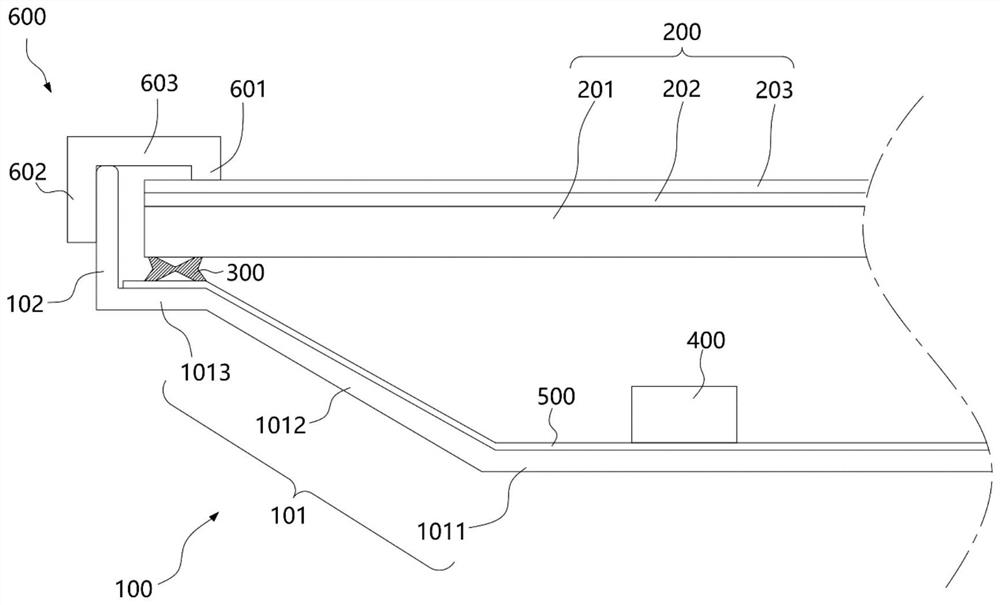

[0039] The embodiment of the present application discloses a backlight module, such as figure 1 As shown, it includes a backplane 100 , an optical film layer 200 , an elastic buffer 300 , a light source 400 , a reflection sheet 500 and a limiting frame 600 . Wherein, the elastic buffers 300 on both sides are arranged between the edge of the optical film layer 200 and the back plate 100, the optical film layer 200 can be supported by the elastic buffers 300; and, since the elastic buffers 300 on both sides have The elastic buffer force, therefore, plays a certain buffering role on the optical film layer 200, avoiding problems such as damage to the diffuser plate; wherein, when the optical film layer 200 is placed horizontally, the elastic buffer member 300 exerts an upward elastic force on the optical film layer 200 Support force, and cooperate with the limit frame 600, clamp the optical film layer 200 between the elastic buffer 300 and the limit frame 600, avoid the optical fi...

Embodiment 2

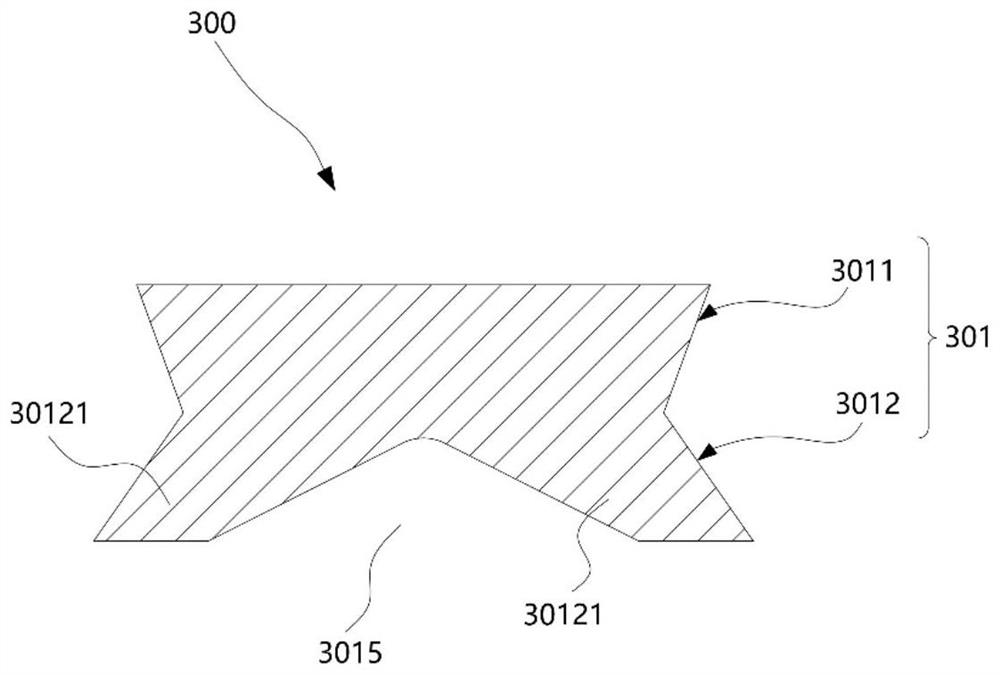

[0071] The difference between Embodiment 2 and Embodiment 1 is that, as image 3 and Figure 4 As shown, the elastic buffer 300 also includes an upper adsorption groove 3014, and the upper adsorption groove 3014 is arranged on the upper part of the elastic buffer 300, wherein the upper adsorption groove 3014 is arranged on the opposite side of the lower adsorption groove 3015, and The lower adsorption groove 3015 is connected to the side away from the fixing plate 1013 , the opening of the upper adsorption groove 3014 faces the side of the diffuser plate 201 , and the end faces of the two ends of the opening are abutted and connected with the diffuser plate 201 .

[0072] It should be noted that, if Figure 4 As shown, the specific structure of the upper adsorption groove 3014 and the lower adsorption groove 3015 is the same, and the vacuum adsorption principle is the same as that of the lower adsorption groove 3015 and the fixed plate 1013, so it will not be repeated here; i...

Embodiment 3

[0075] The difference between embodiment three and embodiment two is that, as Figure 5 and Image 6 As shown, the elastic buffer 300 also includes an elastic extension part 302, and the elastic extension part 302 is respectively connected with the film layer of the lower adsorption groove 3015 near the side plate 102 and the upper adsorption groove 3014 near the side plate 102. The film layer is connected, and forms a through hole 3013 with the lower adsorption groove 3015 and the upper adsorption groove 3014, so as to better provide elastic deformation capability; in addition, the elastic extension part 302 is along the vertical direction from the fixed plate 1013 to the diffuser plate 201 direction, and abut against the diffusion plate 201, the diffusion film 203, and the enhancement film 202 on the side close to the side plate 102, so as to abut against the edges of the diffusion plate 201, the enhancement film 202, and the diffusion film 203. The elastic buffer 300 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com