Power supply line connecting device of electric locomotive

A technology of connecting device and electric locomotive, applied in the direction of connection, circuit, collector, etc., can solve the problems of failure, potential safety hazard, affecting the power supply and operation of the mine, etc., to extend the service life, ensure safety, reduce collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

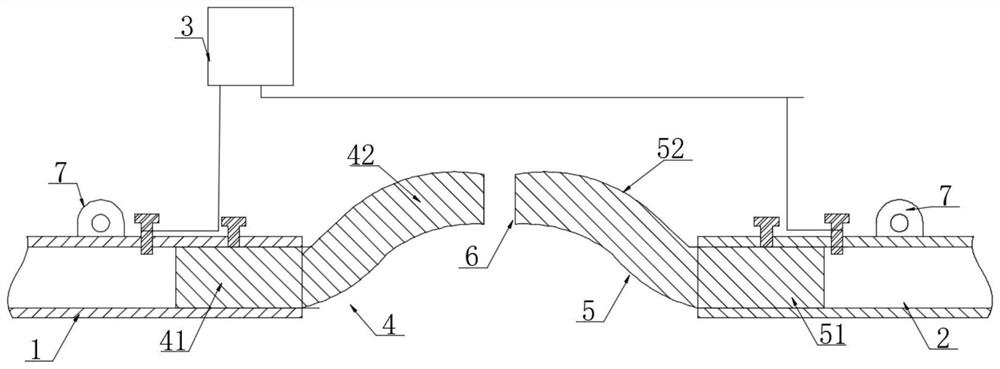

[0024] Example 1, such as figure 1 As shown, a power supply line connecting device of an electric locomotive comprises adjacent first galvanized pipe 1, second galvanized pipe 2 and section switch 3, and a terminal of said section switch 3 is connected to the first galvanized pipe The galvanized pipe 1 is connected, and the other terminal is connected with the second galvanized pipe 2, and also includes a first insulating rod 4 connected with the first galvanized pipe 1 and a second insulating rod connected with the second galvanized pipe 2 5. There is a gap 6 between the first insulating rod 4 and the second insulating rod 5 .

[0025] The first insulating rod 4 includes a first connecting portion 41 and a first bending portion 42, the first connecting portion 41 is inserted into the first galvanized pipe 1 and locked by bolts, and the first bending portion The bending direction of 42 is upward. The connecting part of the insulating rod is inserted and matched with the galv...

Embodiment 2

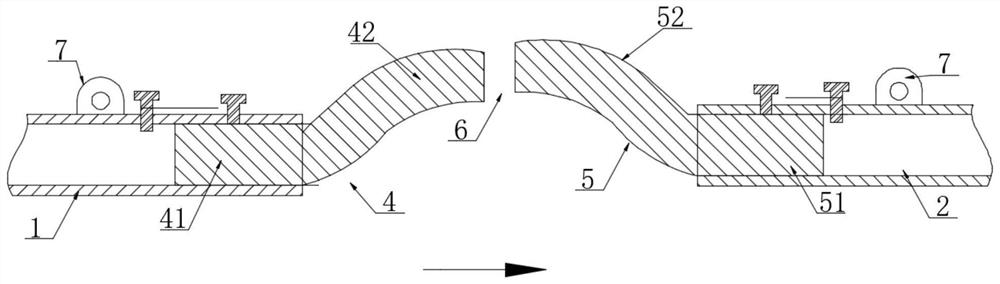

[0029] Example 2, such as figure 2 As shown, on the basis of Embodiment 1, the electric locomotive drives from the first galvanized pipe 1 to the second galvanized pipe 2, and the centerline of the second curved portion 52 is higher than the first curved Centerline of section 42. Although the reduction of the gap 6 and the design of the bending part can satisfy the smooth passage of the pantograph through the neutral position, in order to further reduce the wear of the end of the bending part by the pantograph at the position of the gap 6, the bending part that is heading towards The setting position is higher, further reducing the contact between the pantograph and the end of the bending part, and further improving the transition effect of the pantograph in neutral.

Embodiment 3

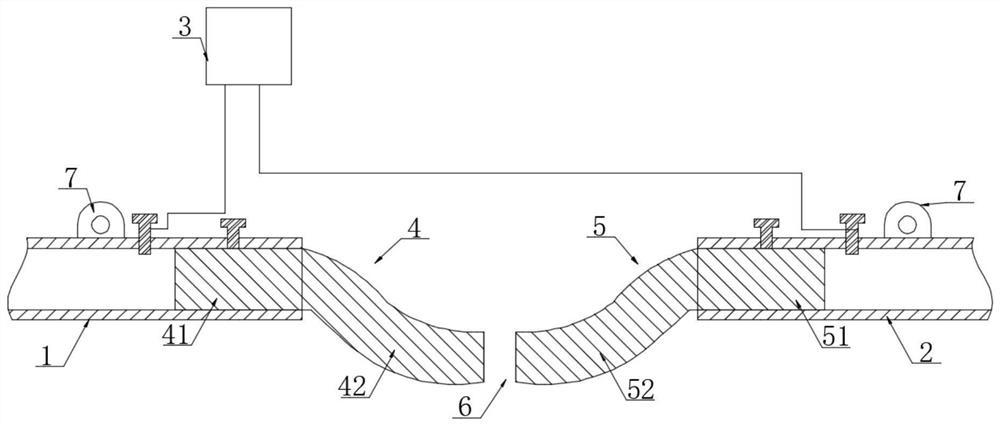

[0030] Example 3, such as image 3 As shown, the first insulating rod 4 includes a first connecting portion 41 and a first bending portion 42. The first connecting portion 41 is inserted into the first galvanized pipe 1 and locked by bolts. A bending direction of the bending portion 42 is downward. The connecting part of the insulating rod is plugged and matched with the galvanized pipe. There are bolt holes on the galvanized pipe. The rod of the bolt passes through the bolt hole and acts on the connecting part to realize the connection between the insulating rod and the galvanized pipe. The downward bending part is matched. Forming a concave design can also cooperate with the elastic force of the pantograph to ensure that the pantograph passes through the gap 6 smoothly.

[0031] The second insulating rod 5 includes a second connecting portion 51 and a second bending portion 52, the second connecting portion 51 is inserted into the second galvanized pipe 2 and locked by bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com