Industrial control prevention and control terminal with various safety structures

A technology of safety structure and industrial control, which is applied in the direction of cleaning method, cleaning method and utensils, casing/cabinet/drawer parts, etc. by using gas flow, which can solve inconvenient cleaning, easy dust collection, accidental touch, etc. problems, achieve the effect of reducing labor intensity, simple and convenient operation, and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

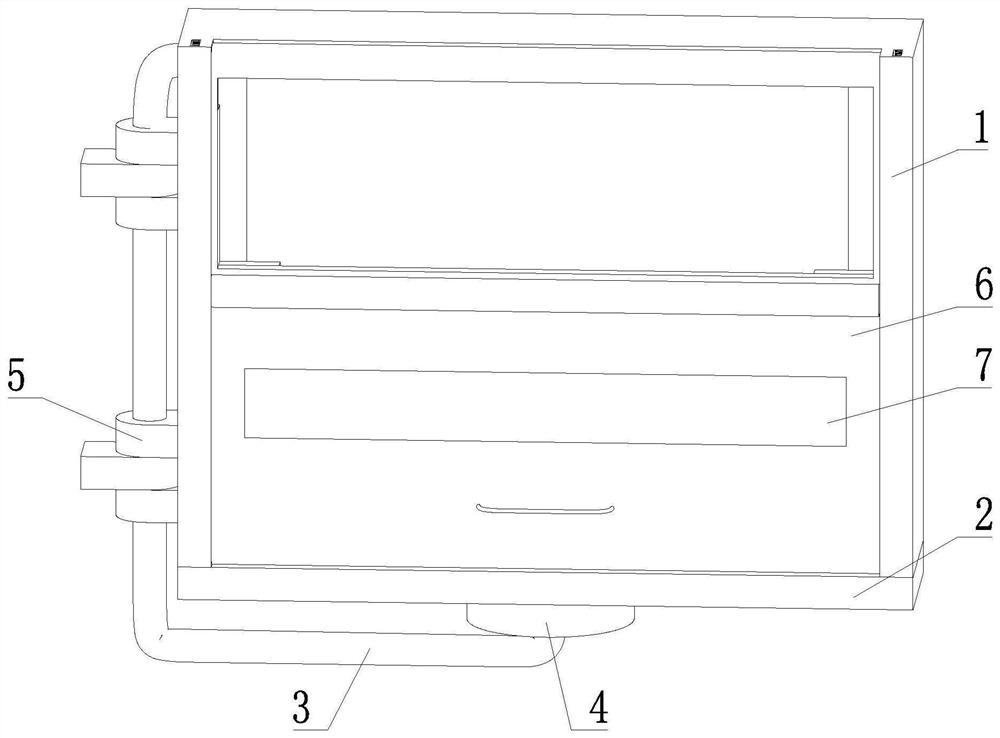

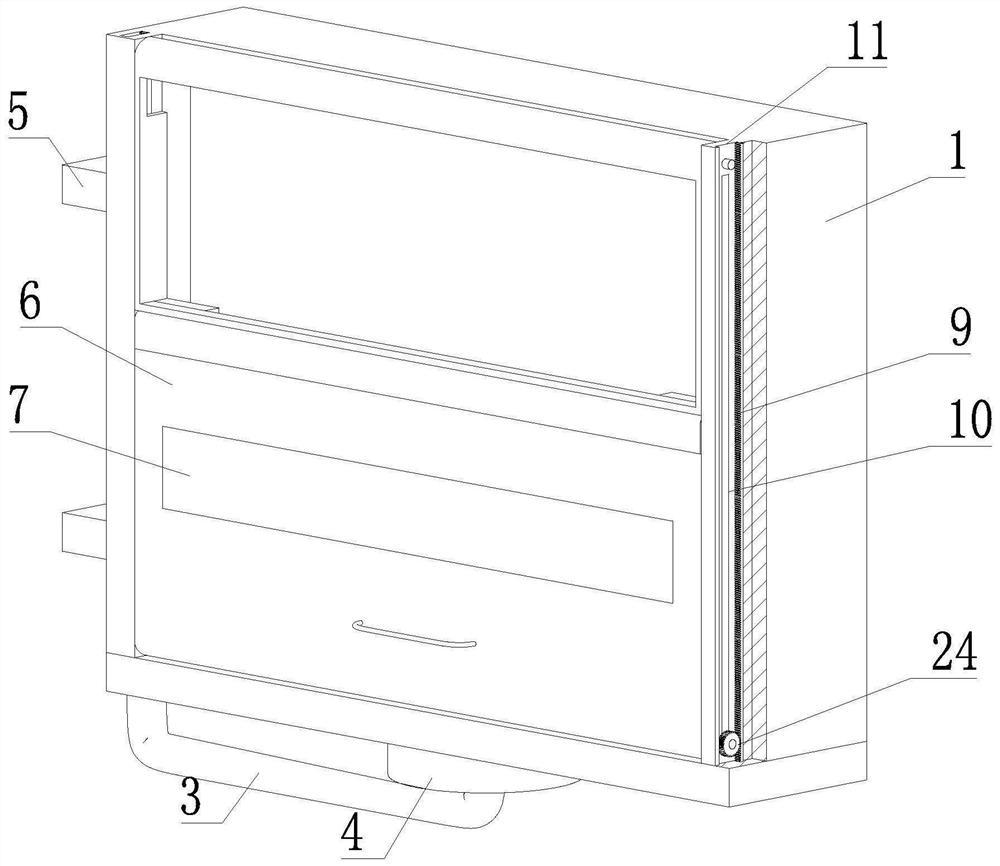

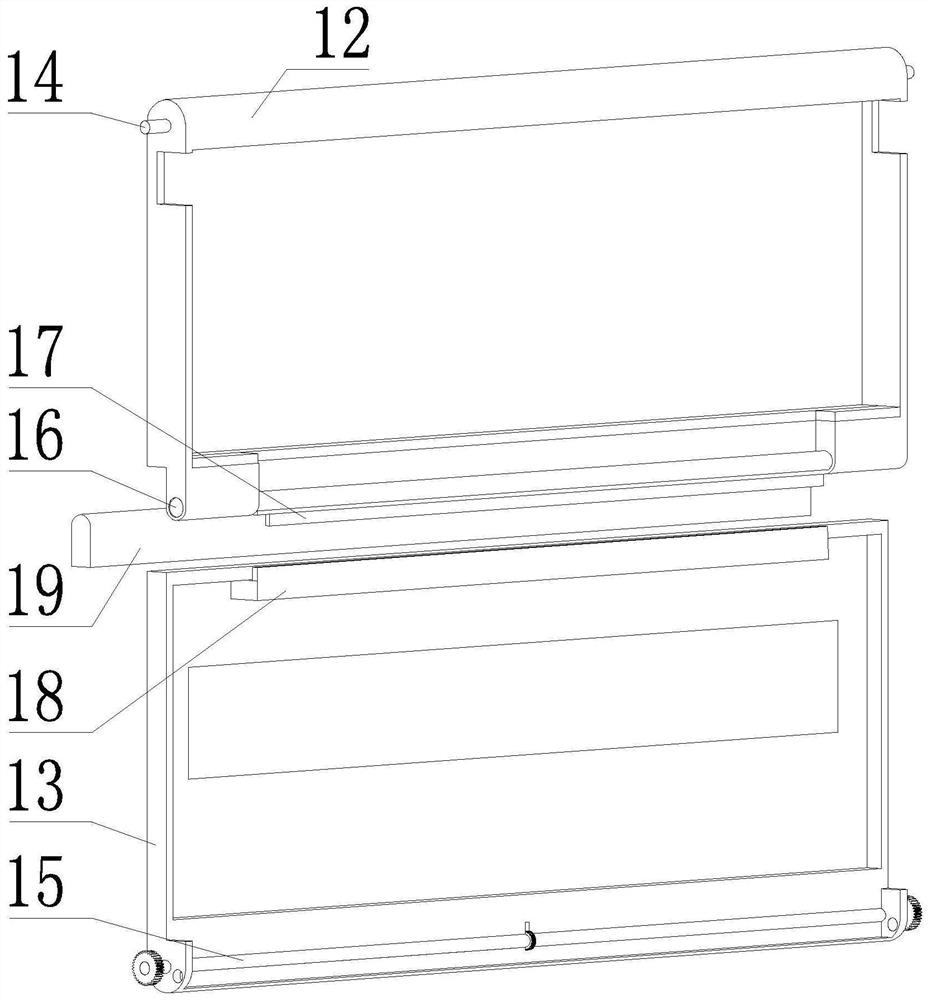

[0030] Such as Figure 1-3 and Figure 6 As shown, the present invention proposes an industrial control terminal with multiple safety structures, including a main body box 1, a main control panel 8, a rack 9 and a power gear 24;

[0031] The main control panel 8 is arranged on the main body box 1, and the limiting groove 10 and the installation groove 11 which communicate with each other are provided on the main body box 1; the rack 9 is arranged on the main body box 1 and is located in the installation groove 11; A protective assembly 6 is provided; wherein, the protective assembly 6 includes a protective cover A12, a protective cover B13, a rotating shaft C16 and a fixed sleeve 18; the protective cover A12 is provided with a rotating shaft A14, and the rotating shaft A14 is rotatably connected with the main body box 1; the rotating shaft C16 is rotatably set On the protective cover A12 and on the side away from the rotating shaft A14, and a fixing member 17 is provided on t...

Embodiment 2

[0034] Such as Figure 1-2 As shown, the present invention proposes an industrial control terminal with various safety structures. Compared with Embodiment 1, this embodiment also includes a support plate 2 and an installation pipe 3; the support plate 2 is arranged on the main box 1 , and the support plate 2 is provided with a tray 4; the installation pipe 3 is arranged on the tray 4 and connected with the main body box 1, and the installation pipe 3 is provided with a mounting part 5 for fixing; it is convenient for installation.

Embodiment 3

[0036] The present invention proposes an industrial control control terminal with various safety structures. Compared with Embodiment 1 or Embodiment 2, the difference between this embodiment is as follows Figure 4-5 As shown, the protective cover B13 is provided with a cleaning assembly 7; wherein the cleaning assembly 7 includes a micro vacuum cleaner 20, a dust cover 22, a rotating shaft D25 and a driven gear A27; the rotating shaft D25 is rotatably arranged on the protective cover B13, and the rotating shaft D25 is provided Cleaning brush 26; rotating shaft D25 is provided with driven gear B28, driven gear A27 is arranged on rotating shaft B15 and is connected with driven gear B28 meshing transmission; micro-vacuum cleaner 20 is arranged on protective cover B13, and micro-vacuum cleaner 20 is provided with Dust collection box 21; dust removal cover 22 is arranged on the protective cover B13 and against the dust collection box 21; dust collection cover 23 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com