Hole taking method for sheet metal part

A technology of sheet metal parts and parts, which is applied in aircraft parts, transportation and packaging, etc., can solve the problems of strength impact and affect the structural strength of parts, and achieve the effect of ensuring the strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

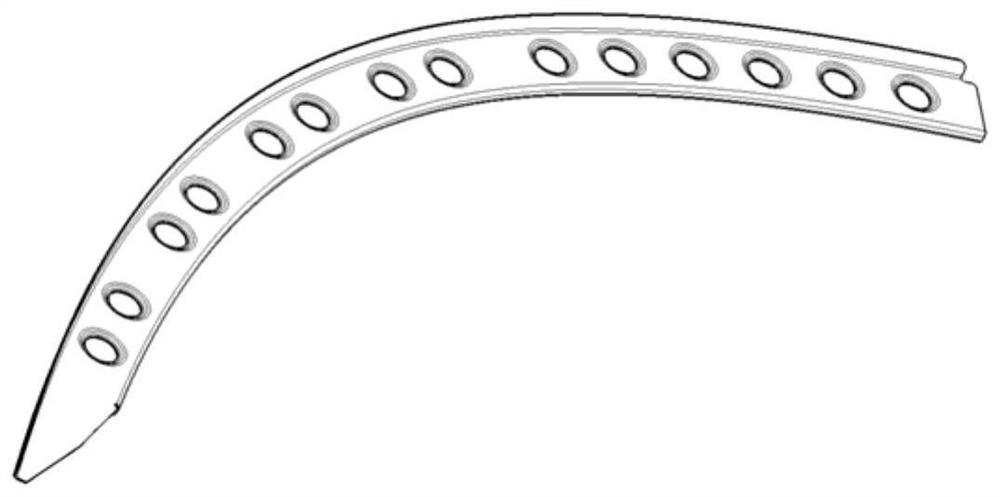

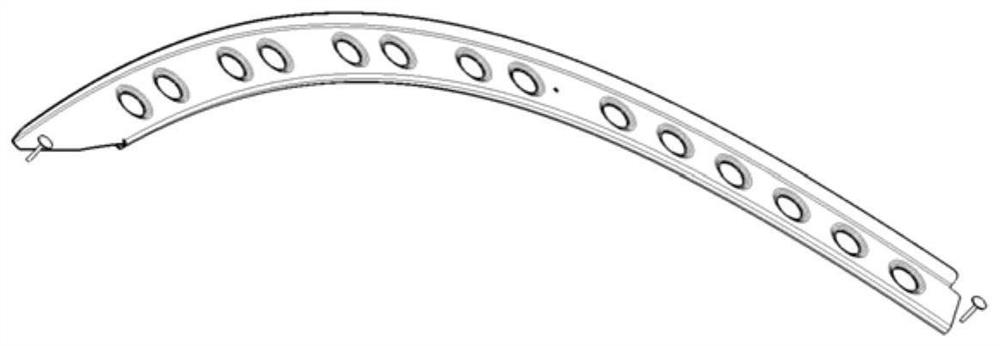

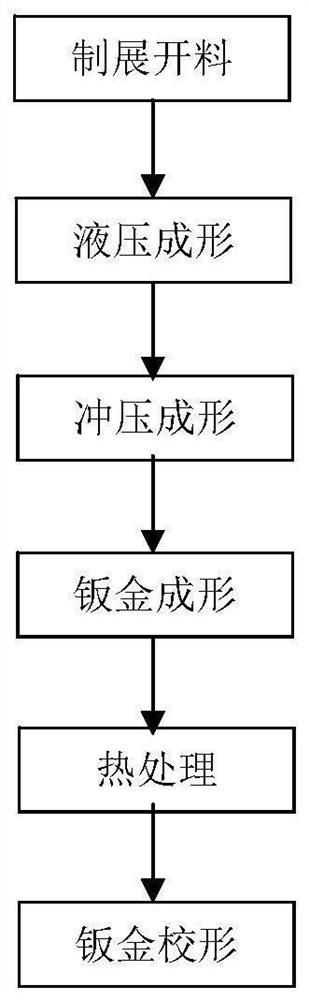

[0039] by figure 1 The part shown is taken as an example to explain the forming process of the part in detail, please refer to figure 2 , the status diagram of the position of the positioning hole of the part before the improvement, the part structure of this embodiment is simple, and the lightening holes are arranged in an arrangement structure. Through the unique hole design, the present invention selects the inner hole of the pin on the large part, and finally flushes it out as a process hole to avoid remaining on the part. At the same time, the strength requirement of the design can be fully guaranteed after the part is formed. See the process for details. image 3 :

[0040] (1) Manufacture of unfolded materials

[0041] Calculate the size of the unfolded material according to the specific part. At the same time, the size of the reference hole of the fifth lightening hole from the left of the part is required to be Φ6. This hole is used for the positioning of the part ...

Embodiment 2

[0053] This embodiment is similar to embodiment 1, adopts similar parts to carry out hole extraction, just selects the lightening hole of different position as reference hole to carry out hole extraction, process is as follows:

[0054] (1) Manufacture of unfolded materials

[0055] Calculate the size of the unfolded material according to the specific part, and at the same time require the reference hole size of the 8th lightening hole from the left of the part to be Φ6. This hole is used for positioning the part in the hydroforming process to prevent the part from being "pulled" during the forming process. At the same time, it is used for The positioning of the thimble of the punching die for the relief hole in the stamping process is to improve the precision of punching the relief hole, and the remaining relief holes are Φ20.

[0056] (2) Hydroforming

[0057] This step is more critical and is the basis of the follow-up process. Two sets of molds are required for forming. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com