Burr grinding equipment used after steel pipe cutting

A burr and steel pipe technology, applied in the field of burr grinding equipment after steel pipe cutting, can solve the problems of low work efficiency and labor, and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: A kind of burr grinding equipment after steel pipe cutting.

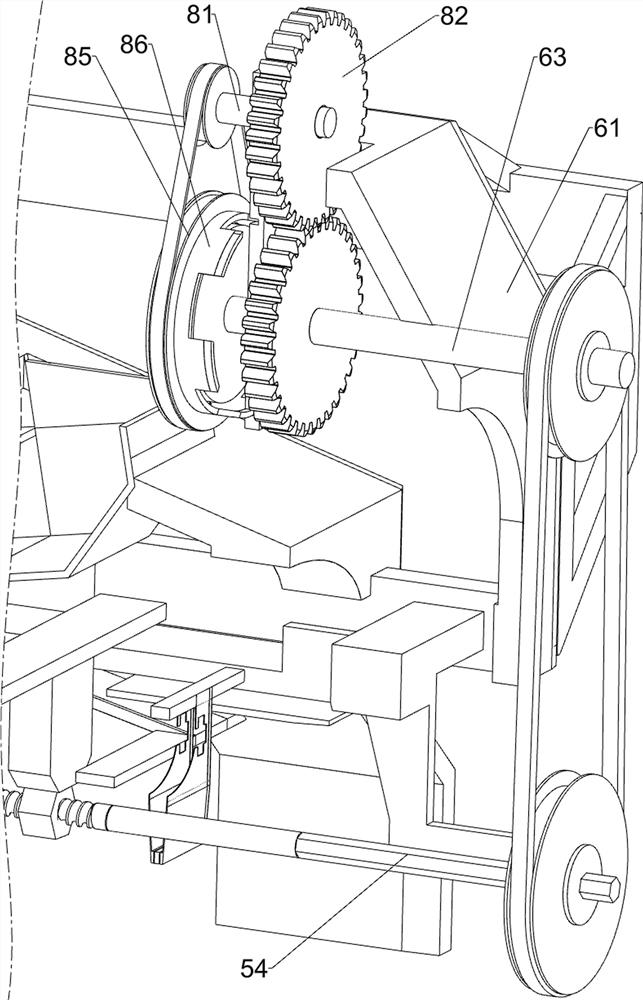

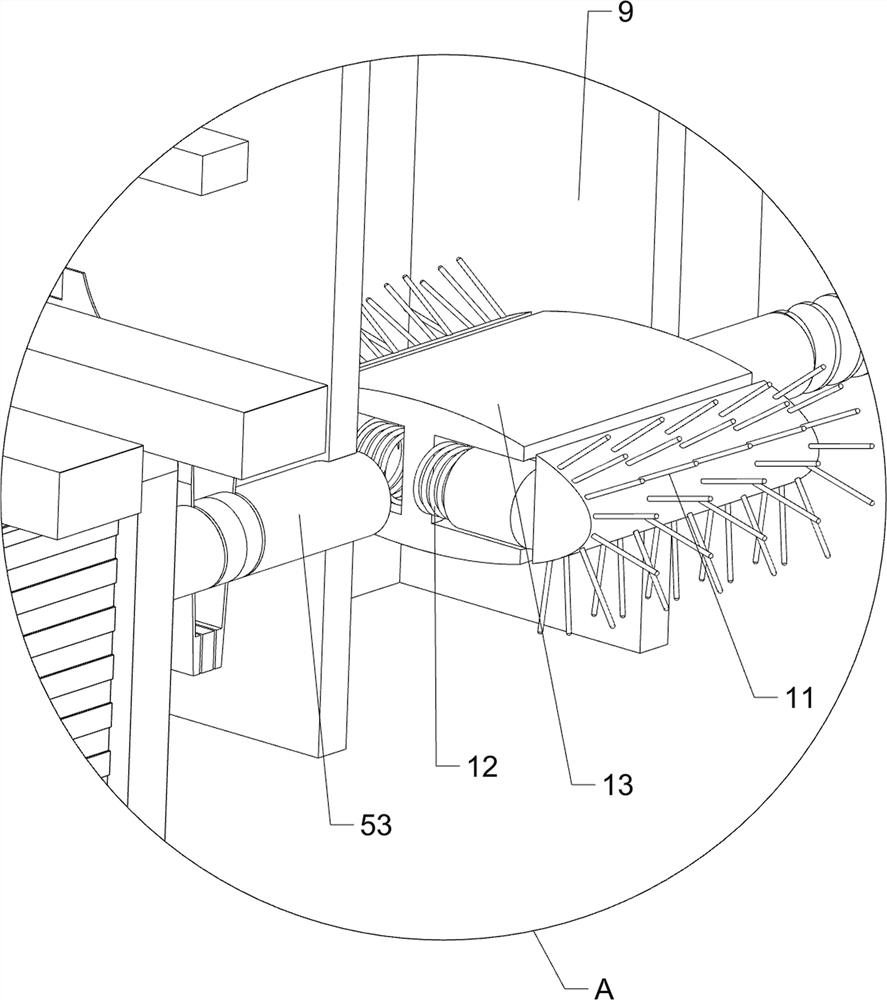

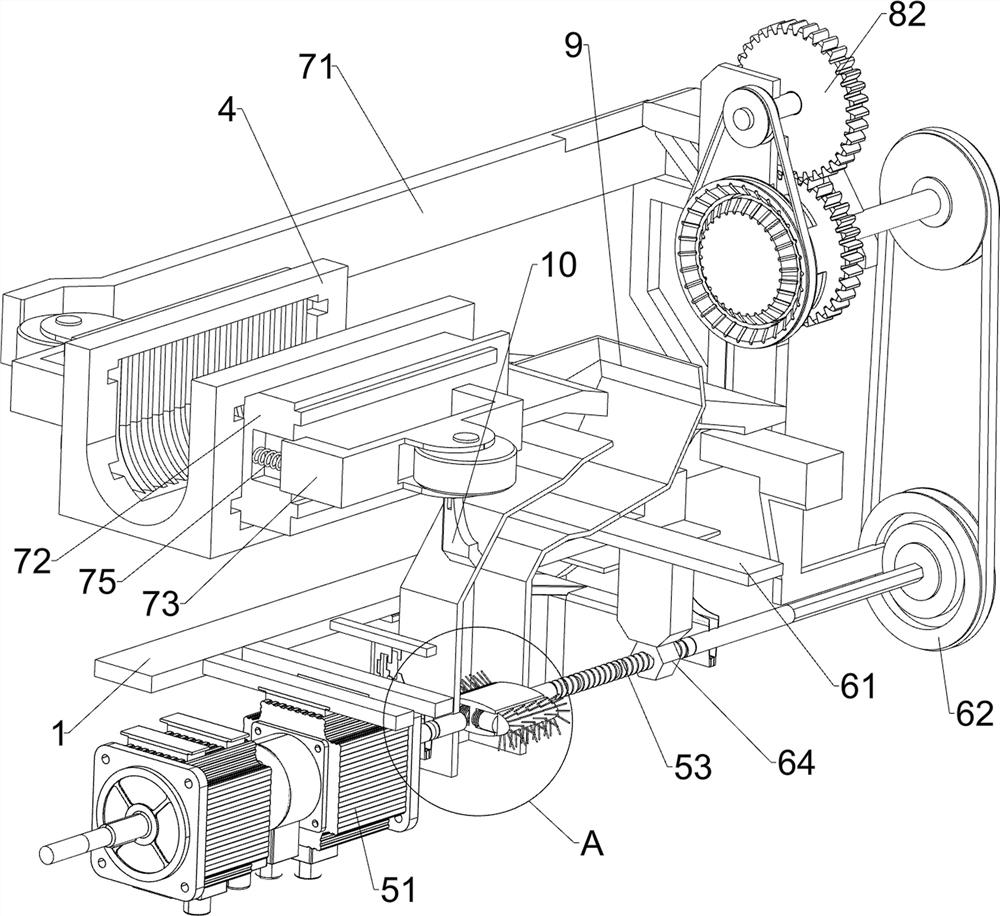

[0024] refer to figure 1 and figure 2 As shown, it includes a mounting frame 1, a support seat 2, a grinding disc 3, a u-shaped placement seat 4, a driving mechanism 5, and a guiding mechanism 6. The left and right sides of the outer bottom of the mounting frame 1 are fixedly connected with the supporting seat 2, and the mounting frame 1 The middle of the outer top is fixedly connected with a U-shaped placement seat 4, and the left and right sides of the mounting frame 1 are provided with a guide mechanism 6. The mechanism 5 is slidingly matched with the guide mechanism 6 .

[0025] The driving mechanism 5 includes a double-axis motor 51, a riser 52, a screw rod 53 and a hexagonal rod 54. The outer bottom of the mounting frame 1 is symmetrically fixed with a riser 52, and the middle of the lower part of the riser 52 is connected with a screw rod in a rotating manner. 53, screw mandrel 53 threa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap