Grinding mechanism and core column grinder

A technology of grinding mechanism and column grinding, applied in grinding machine tools, grinding devices, grinding/polishing equipment, etc., can solve problems such as restricting the work efficiency of equipment, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

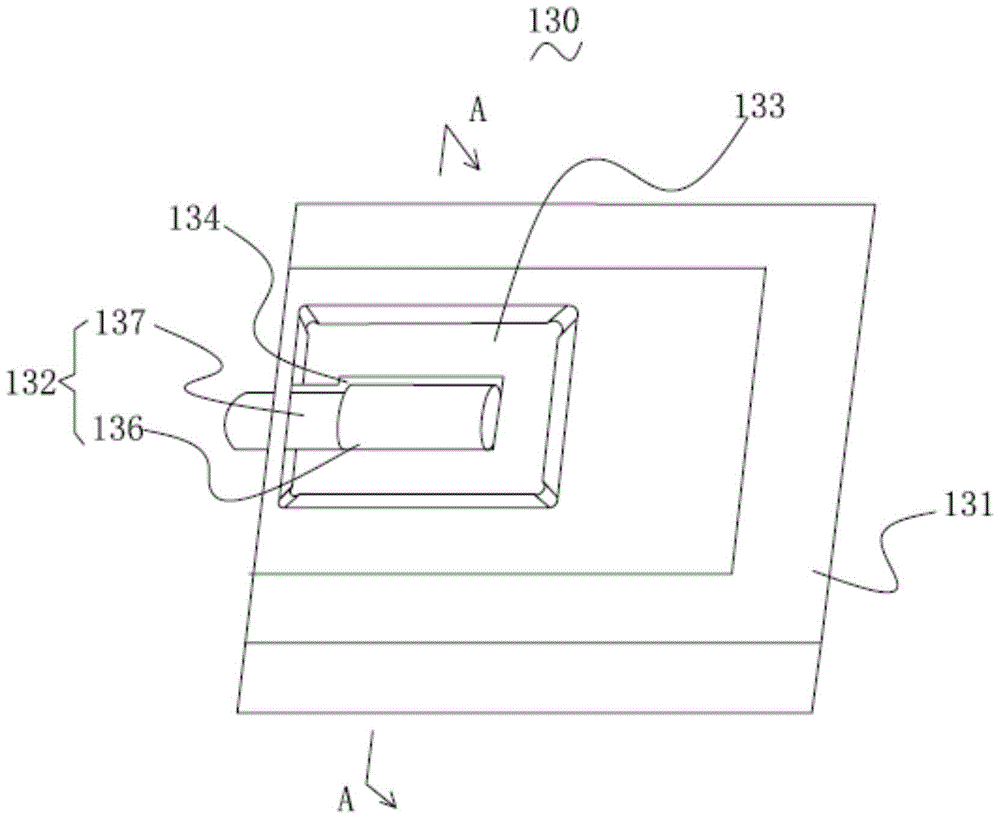

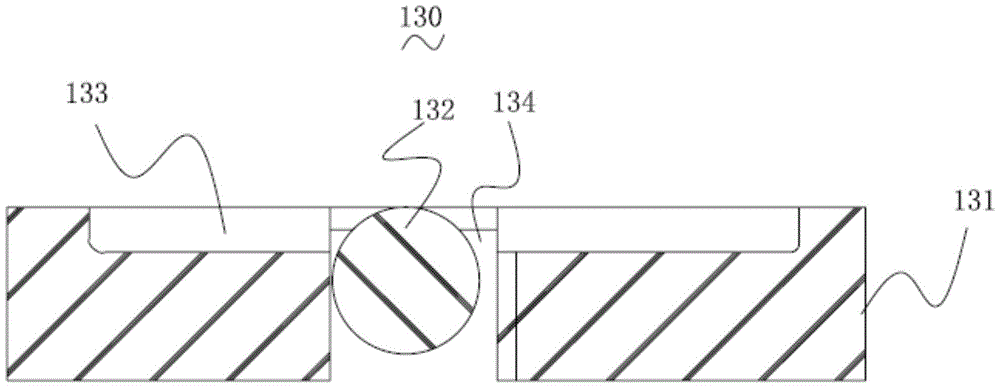

[0032] See attached figure 1 , which is a schematic structural diagram of the grinding mechanism 130 according to an embodiment of the present invention, please refer to the attached figure 2 , which is figure 1 The shown grinding mechanism 130 is a schematic cross-sectional view along line A-A.

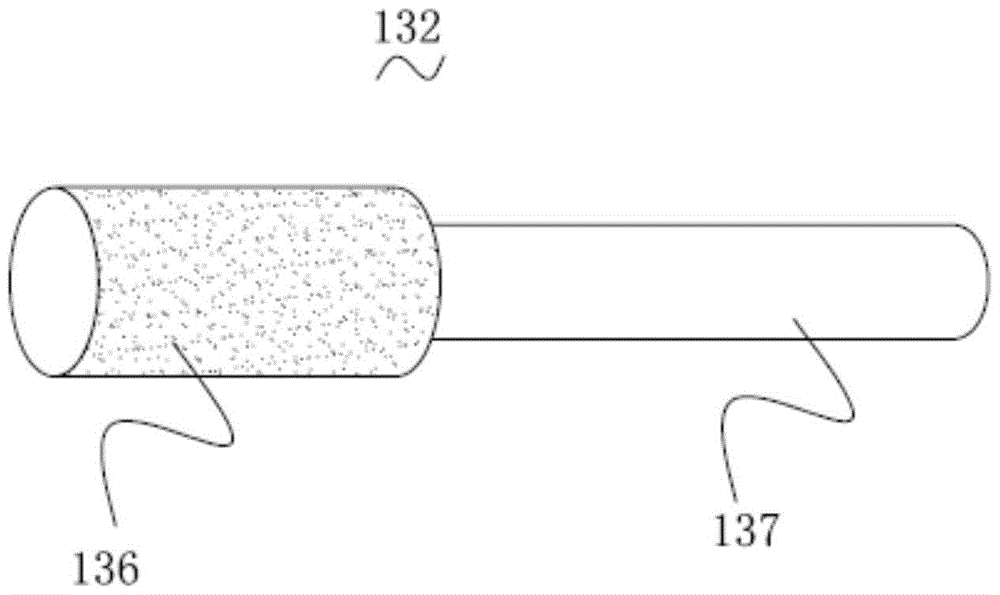

[0033] The grinding mechanism 130 includes a grinding platform 131 and a grinding body 132 . The grinding platform 131 is placed parallel to the grinding body 132 . The grinding body 132 includes a connecting rod 137 and a cylindrical grinding part 136 . The side surface of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap