Mechanical polishing device for faucet production process

A production process and mechanical polishing technology, applied in the direction of grinding/polishing safety device, grinding drive device, grinding/polishing equipment, etc., can solve the problems of labor-intensive, unable to prevent debris splashing, staff injury, etc., To achieve the effect of saving time, better effect and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

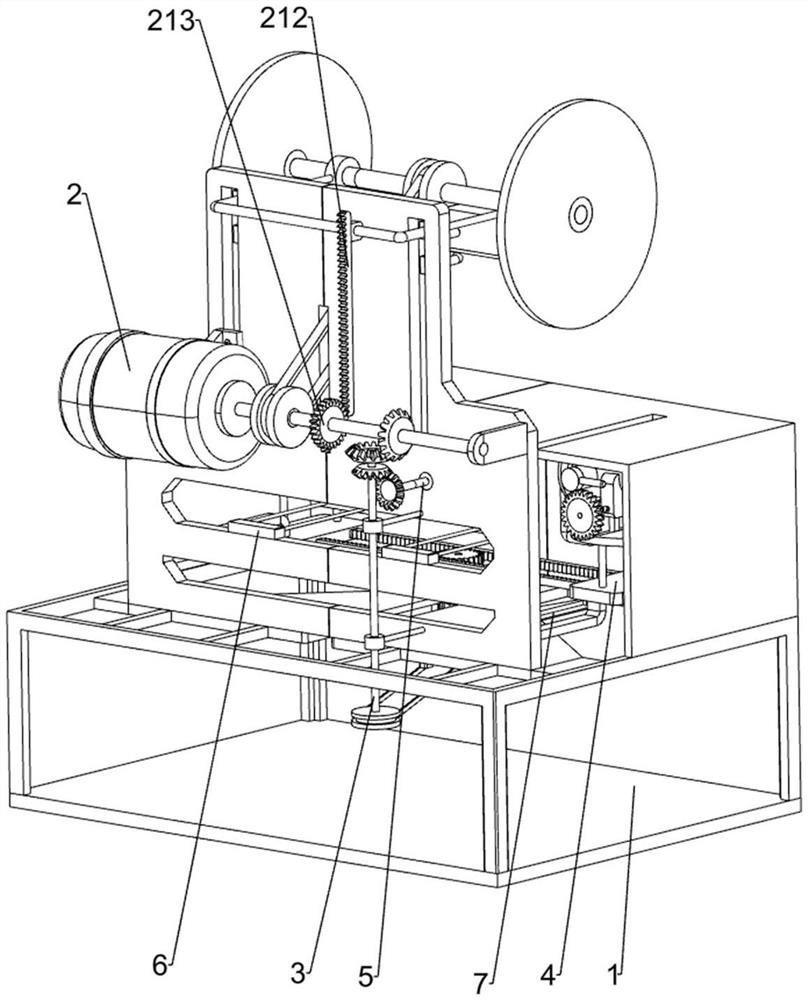

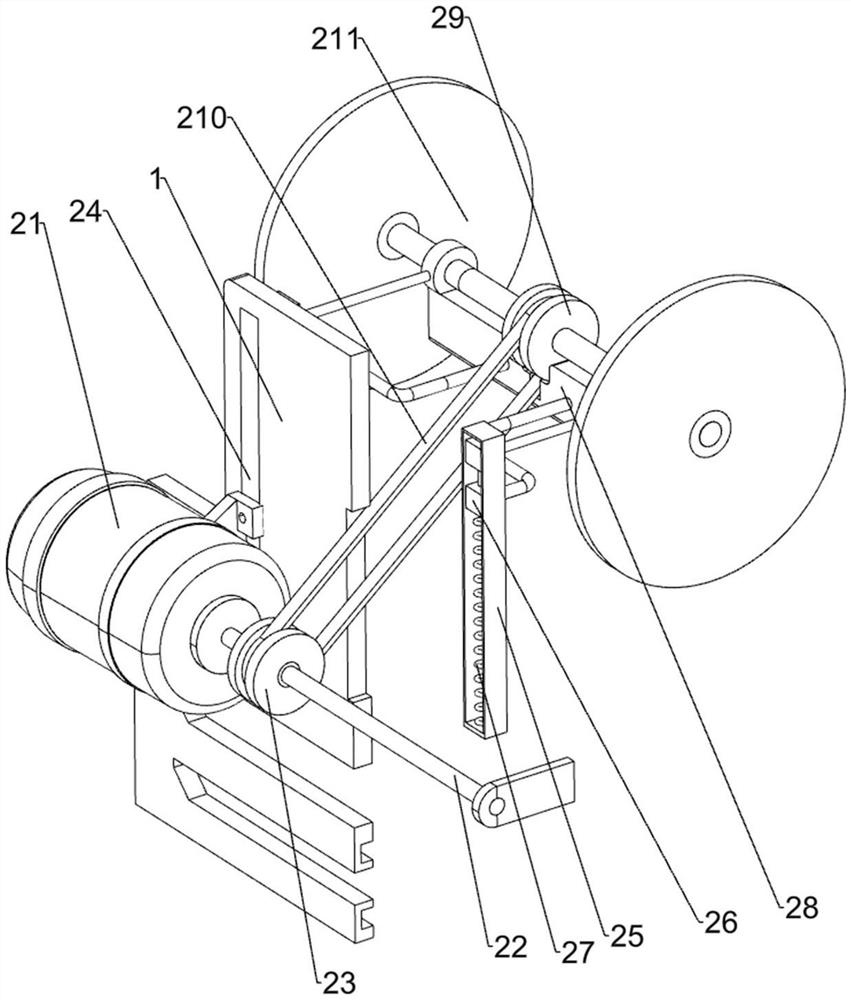

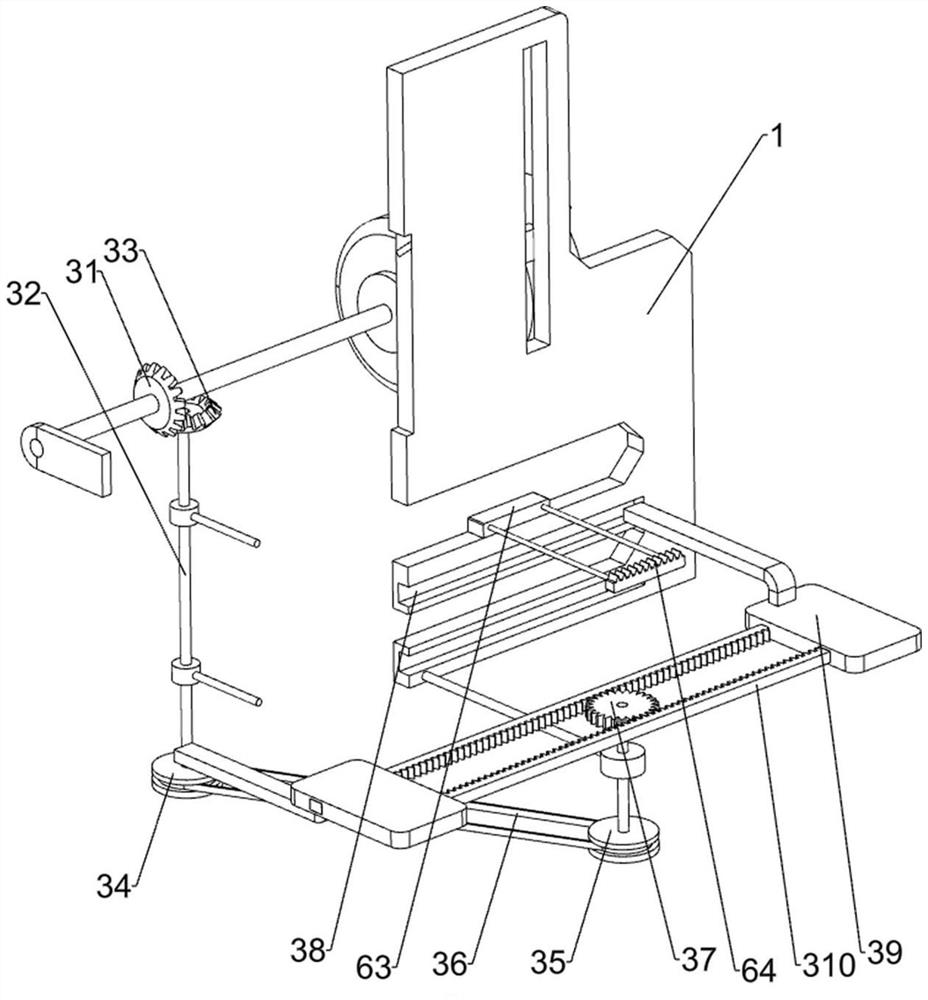

[0026] A kind of mechanical polishing device for faucet production process, such as Figure 1-4 As shown, it includes a mounting frame 1, a polishing assembly 2, a moving assembly 3 and a fixed assembly 4. The upper side of the mounting frame 1 is provided with a polishing assembly 2, and a moving assembly 3 is provided between the mounting frame 1 and the polishing assembly 2. The component 3 is provided with a placing and fixing component 4 .

[0027] When the faucet needs to be polished, the faucet is placed on the fixed assembly 4, and then the polishing assembly 2 is started, and the polishing assembly 2 will polish the faucet, and the polishing assembly 2 will also drive the moving assembly 3 to move, thereby making the polishing Component 2 can polish the faucet in many ways. When the faucet is polished, control the polishing component 2 to operate in reverse, thereby resetting the above-mentioned parts. After resetting, close the polishing component 2, and then take th...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 , image 3 , Figure 4 , Figure 5 and Image 6 Shown, also include cleaning assembly 5, cleaning assembly 5 includes the 3rd bevel gear 51, the 3rd rotating rod 52, the 4th bevel gear 53, the 5th pulley 54, the 3rd flat belt 55 and fan 56, the 2nd rotation The upper side key of bar 32 is connected with the 3rd bevel gear 51, and the front right side of mounting frame 1 is connected with the 3rd rotating rod 52, and the front side key of the 3rd rotating rod 52 is connected with the 4th bevel gear 53, and The four bevel gears 53 mesh with the third bevel gear 51, the rear side of the third rotating rod 52 is connected with the fifth pulley 54, and the left side of the installation frame 1 is also connected with the fifth pulley 54 in a rotational manner, and the fifth pulley 54 is connected A third flat belt 55 is arranged, and a fan 56 is connected to the rear side of the fifth pulley 54 .

[0036] Starting the reduction...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap