Transverse fastening installation device and method for large filter pressing type hydrogen production electrolytic cell

An installation device and electrolytic cell technology, applied in the electrolytic process, electrolytic components, workpiece clamping devices, etc., can solve the problems of difficult installation technology and high infrastructure requirements, reduce the requirements of plant infrastructure and equipment, and reduce investment. cost, the effect of ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

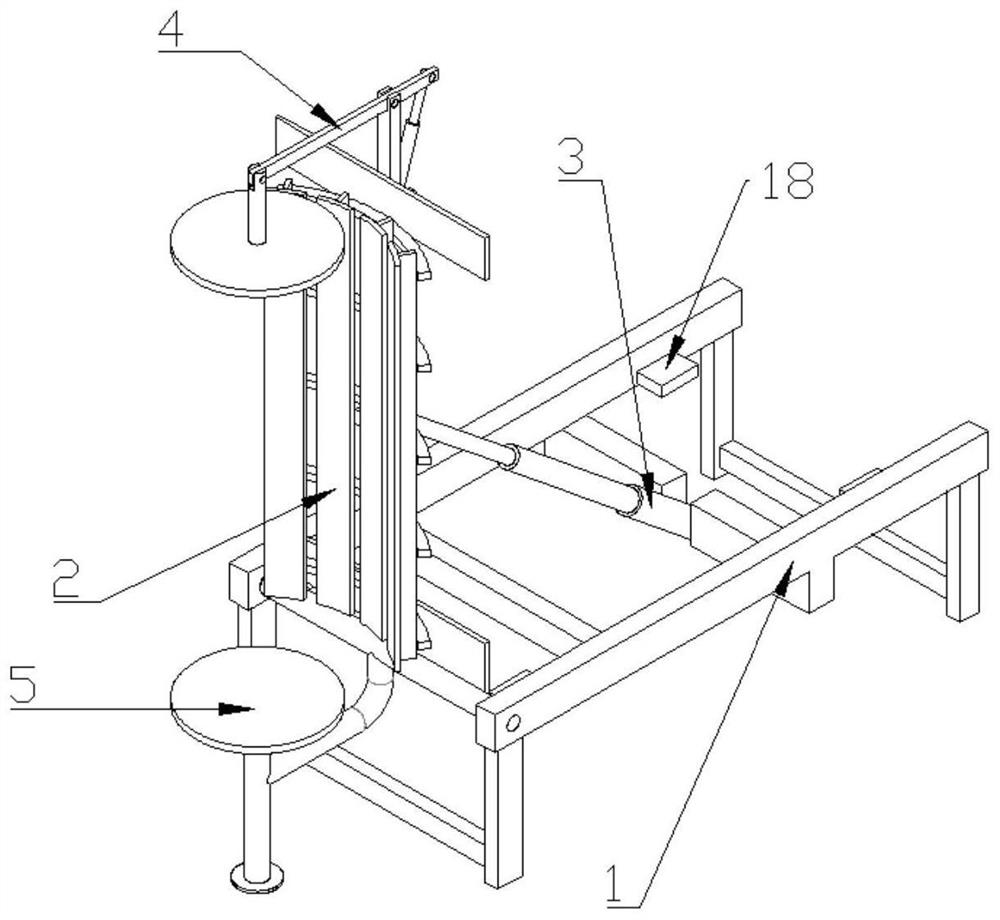

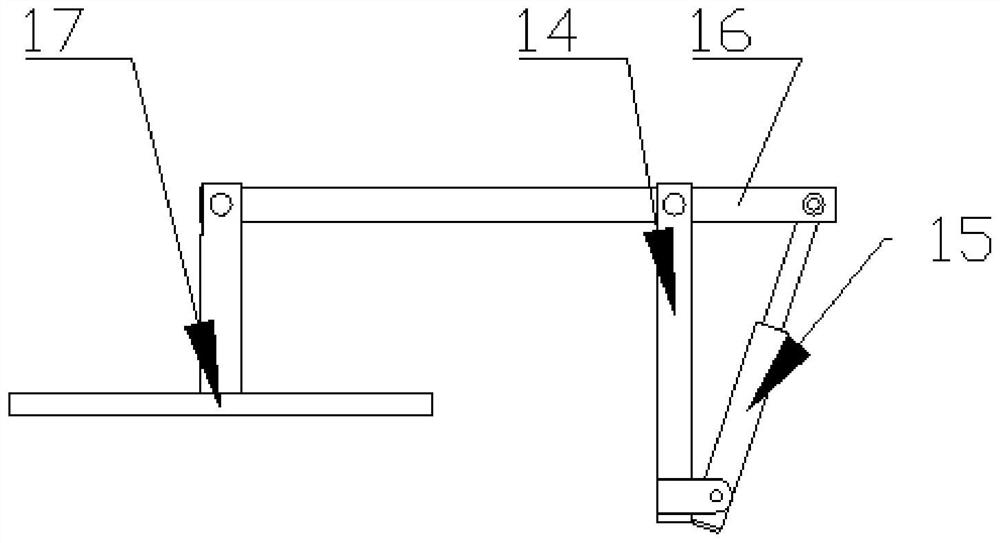

[0034] Such as figure 1 with 2 , the horizontal fastening and installation device for a large-scale filter press type hydrogen production electrolyzer according to the present invention includes a base 1 , an overturning frame 2 , a hydraulic device 3 and a pressing fixture 4 .

[0035] The base 1 is fixed on the level ground, and it should be ensured to be firm and reliable. The base 1 is provided with a number of supporting bosses 18, which play a supporting role when the turning frame 2 turns over to a horizontal position.

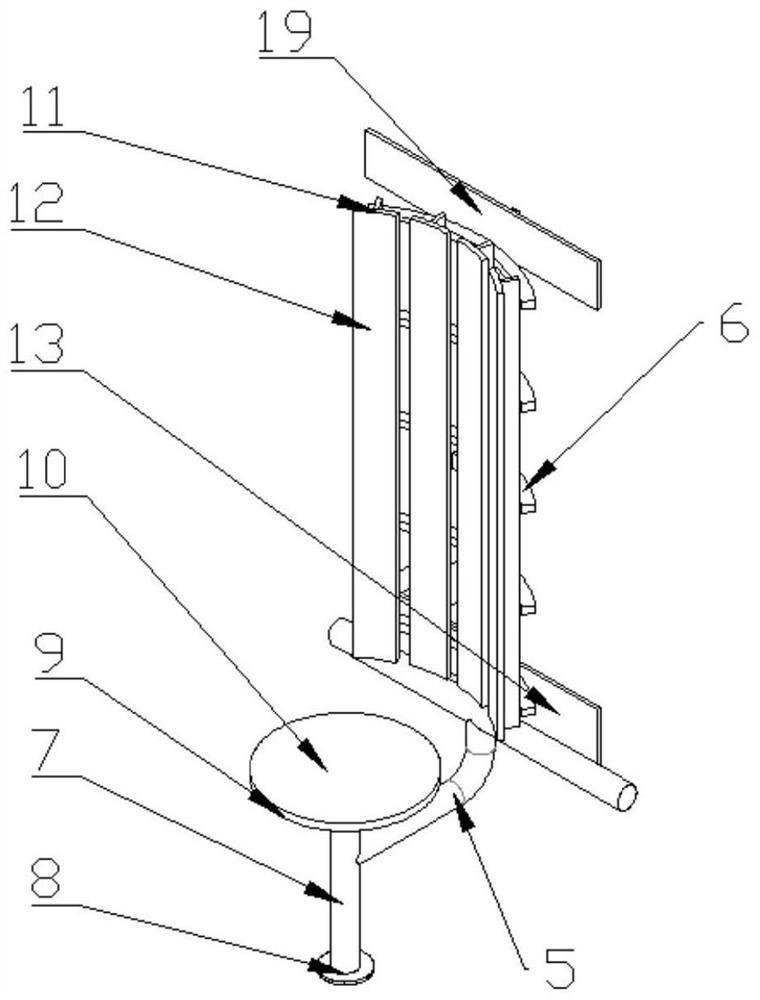

[0036] The flip frame 2 is hingedly mounted on the base 1 . The overturn frame 2 includes a longitudinal support frame 5 and a transverse support frame 6 connected together. The longitudinal support frame 5 has a longitudinal support surface 10 , the transverse sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com