Busbar expansion joint

A technology for expansion joints and busbars, applied in power lines, vehicle components, power rails, etc., can solve problems such as affecting the mechanical compensation function of the expansion joint, deformation of the expansion joint body, and endangering the safety of trains. The effect of small initial slip force and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

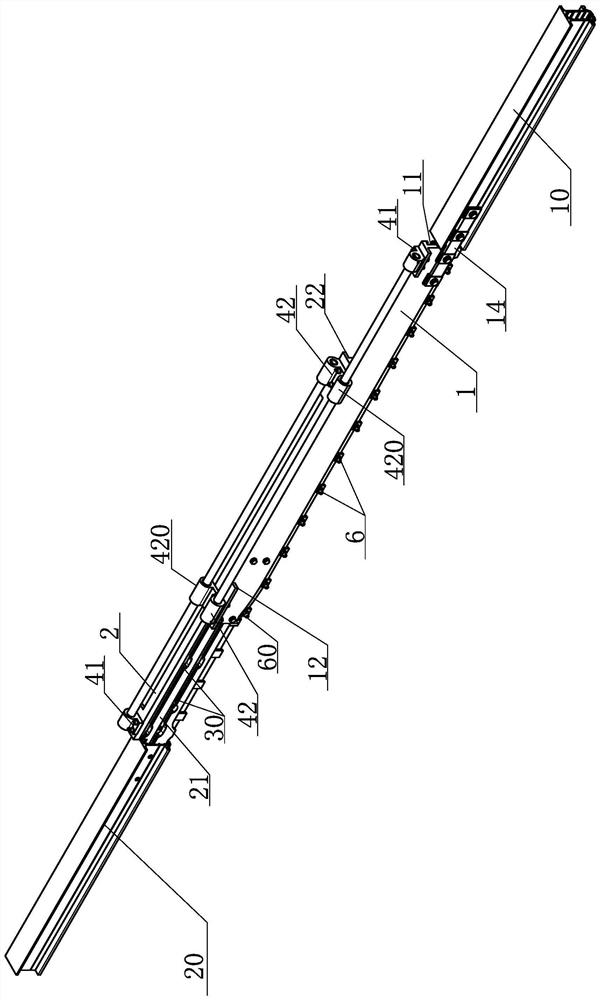

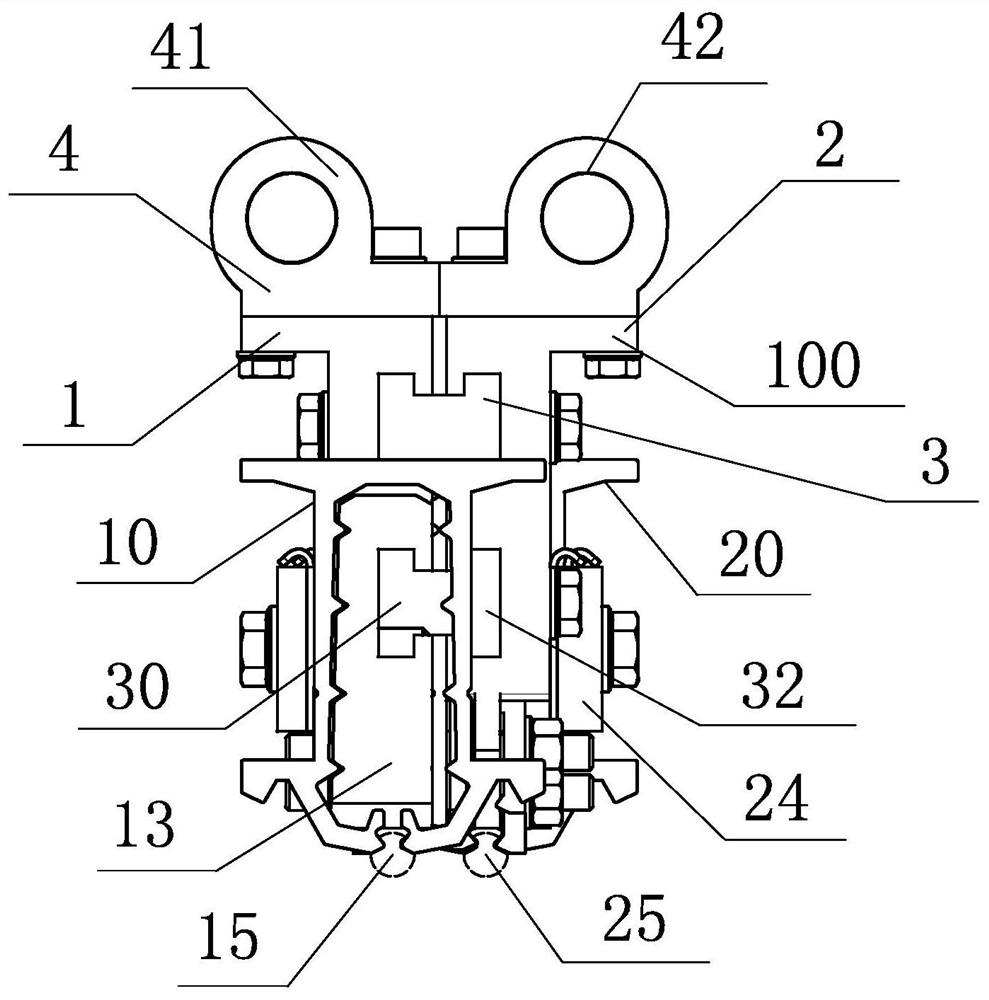

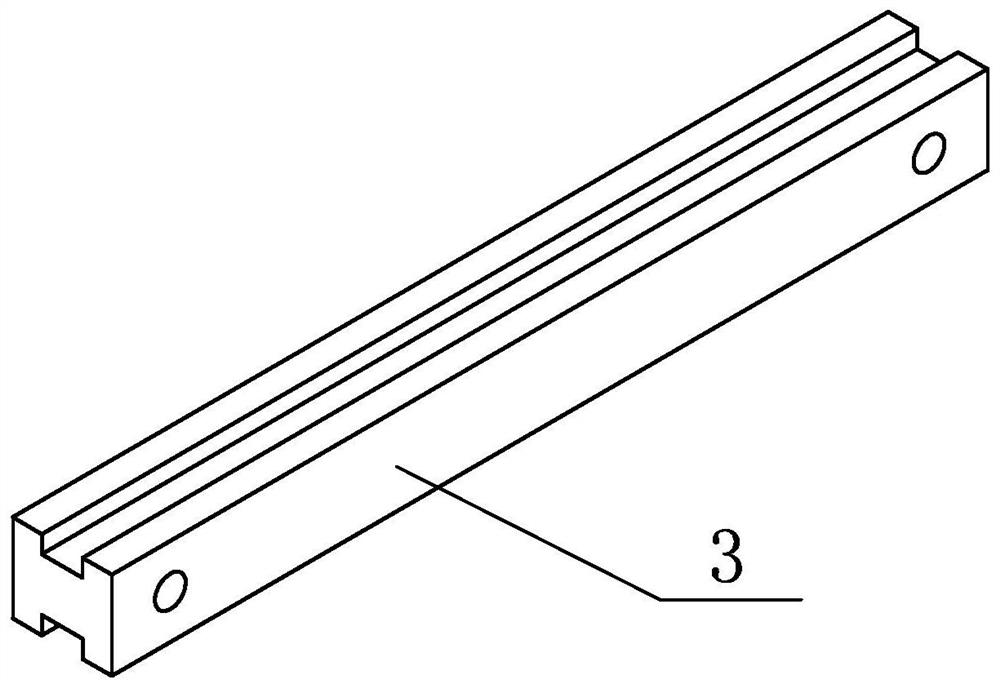

[0043] see Figure 1-Figure 2 As shown, a schematic diagram of the structure of an embodiment of the expansion joint of the bus bar according to the present invention is connected to the bus bar. The expansion joint mainly includes a deflector plate and an electrical connection device 4 . The deflectors are divided into a left deflector 1 and a right deflector 2 which have the same structure and are arranged side by side with the inner sides facing each other at intervals. The left deflector 1 includes a first end 11 and a second end 12 opposite to each other. The first end 11 of the left deflector 1 is fixedly connected to the left bus bar 10; the right deflector 2 also includes opposite first ends 21 and second ends 22, and the first end 22 of the right deflector 2 One end 21 is fixedly connected to the bus bar 20 on the right; two (single or multiple) chutes extending to both ends are provided on the inner sides of the left deflector 1 and the right deflector 2 30, the chu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap