Liquefied gas carrier deck structure

A technology for liquefied gas ships and decks, applied in hull decks, hulls, ship construction, etc., can solve problems such as difficulty in moving people back and forth, inconvenient observation on the upper surface of cargo tanks, etc., to improve transportation efficiency, improve ship type economic benefits and safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

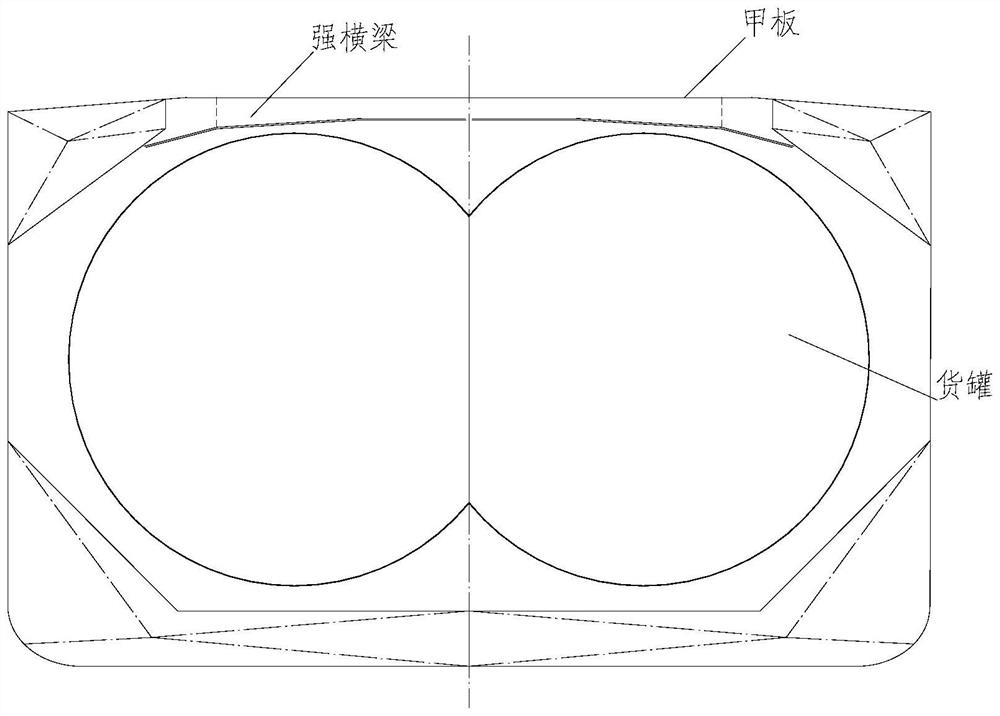

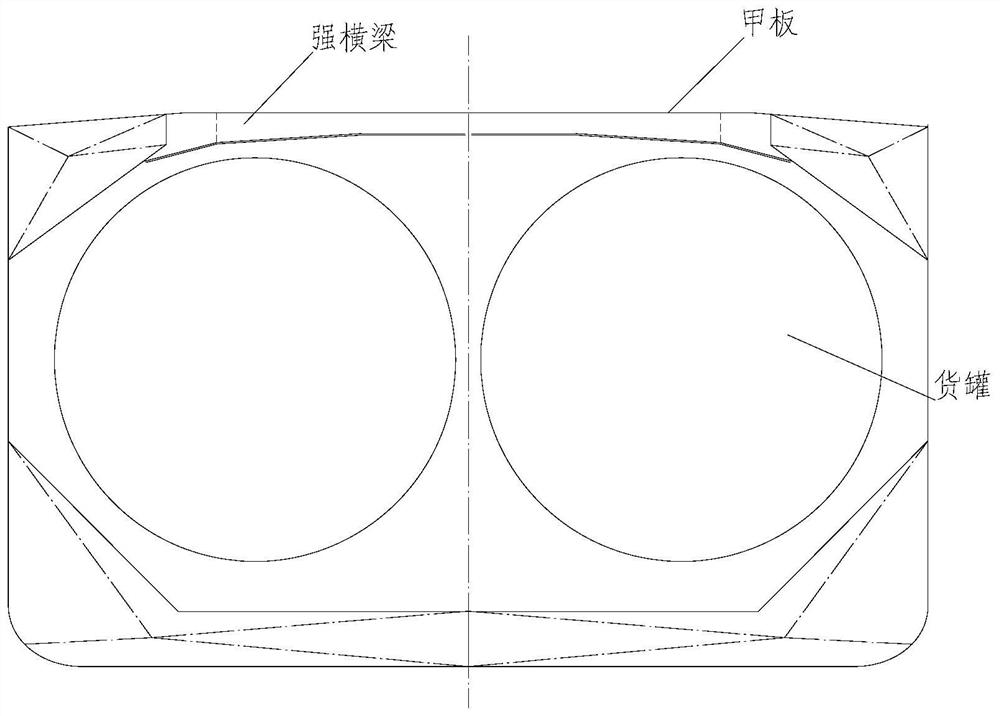

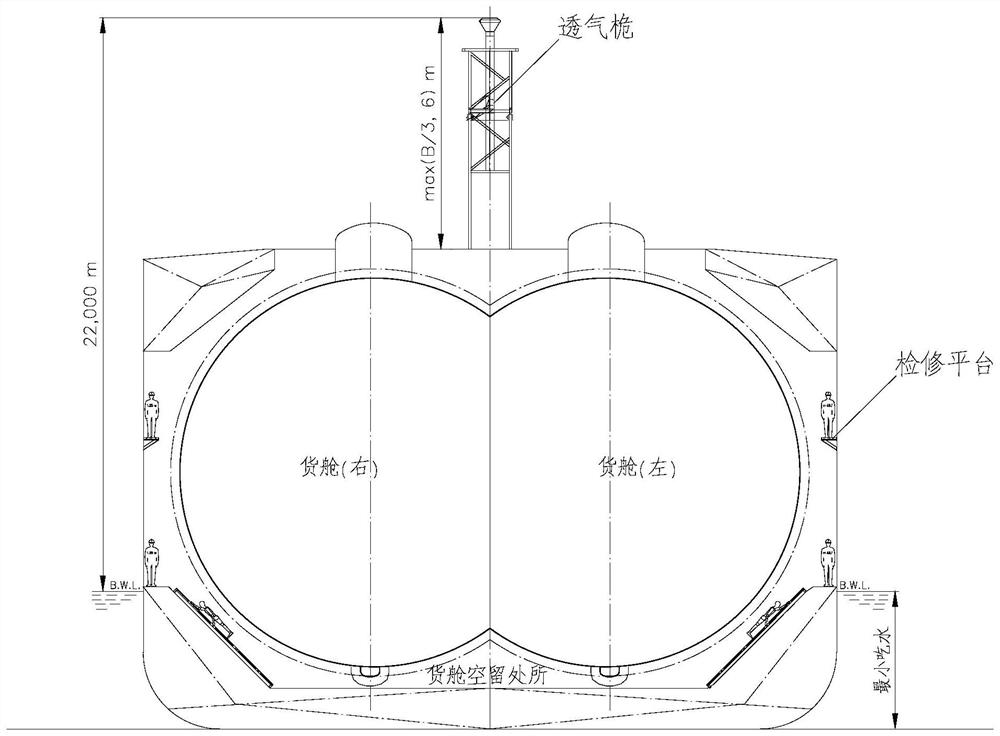

[0035] The main idea of the present invention is to change the strong beam of the exposed deck of the liquefied gas ship from the conventional arrangement under the deck to the arrangement on the deck, as shown in the attached Figure 5 to attach Figure 9 shown.

[0036] First, the deck application area is the cargo hold area of the liquefied gas ship, and the ventilation mast 2 of the liquefied gas ship is arranged on the deck of the cargo hold area. According to the requirements of the specification, the height of the ventilation mast 2 of a liquefied gas ship is measured from the exposed deck 3, and the deck structure such as the deck beam 4 is turned over the exposed deck 3, which will not affect the calculation of the height of the ventilation mast 2. The height of the ventilation mast 2 It can be the same as the scheme of setting strong beams under the deck. Like this, when empty height restriction is certain, the height of the exposed deck 3 that the strong beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com