A preparation device for heat-resistant ultra-high molecular weight polyethylene fiber products

A technology of ultra-high molecular weight and polyethylene fiber, applied in textiles, papermaking, yarn, etc., can solve the problems of difficult storage and storage of phase change heat storage materials, lower tensile strength, and deterioration of material properties, and achieve easy mass production, Good water holding capacity, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing of description and embodiment:

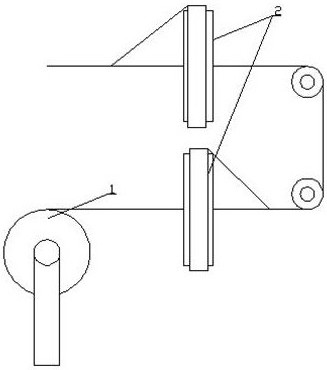

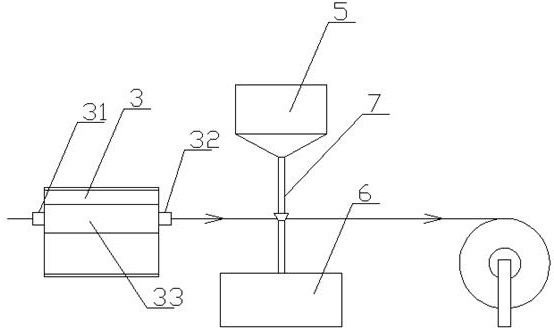

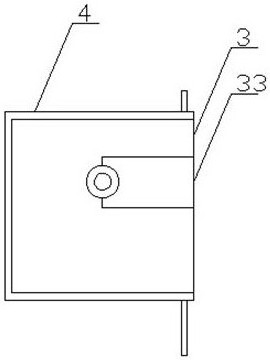

[0023] A preparation device for heat-resistant ultra-high molecular weight polyethylene fiber products, including a winding mechanism, which is used to use heat-resistant ultra-high molecular weight polyethylene fiber as the yarn core, and wind the covering yarn on the yarn core; A water container for the yarn core bypassing the covering yarn to make the covering yarn absorb water; the freezing mechanism has a low-temperature chamber, and when the water-absorbed covering yarn passes through the low-temperature chamber, the water in it condenses into ice to form ice silk; and a paraffin-coating mechanism, which is used to coat the liquid paraffin on the outside of the ice silk and condense rapidly when it is cold to form a dense paraffin layer that prevents water vapor from escaping, and then made the heat-resistant ultra-high molecular weight po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com