Turnover mechanism with self-locking function

A flipping mechanism and self-locking technology, applied in the pivot connection and other directions, can solve the problems of time-consuming and laborious, reduce the practicability of the flipping mechanism, hand injuries, etc., and achieve the effect of preventing hand injuries, improving practicability, saving time and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

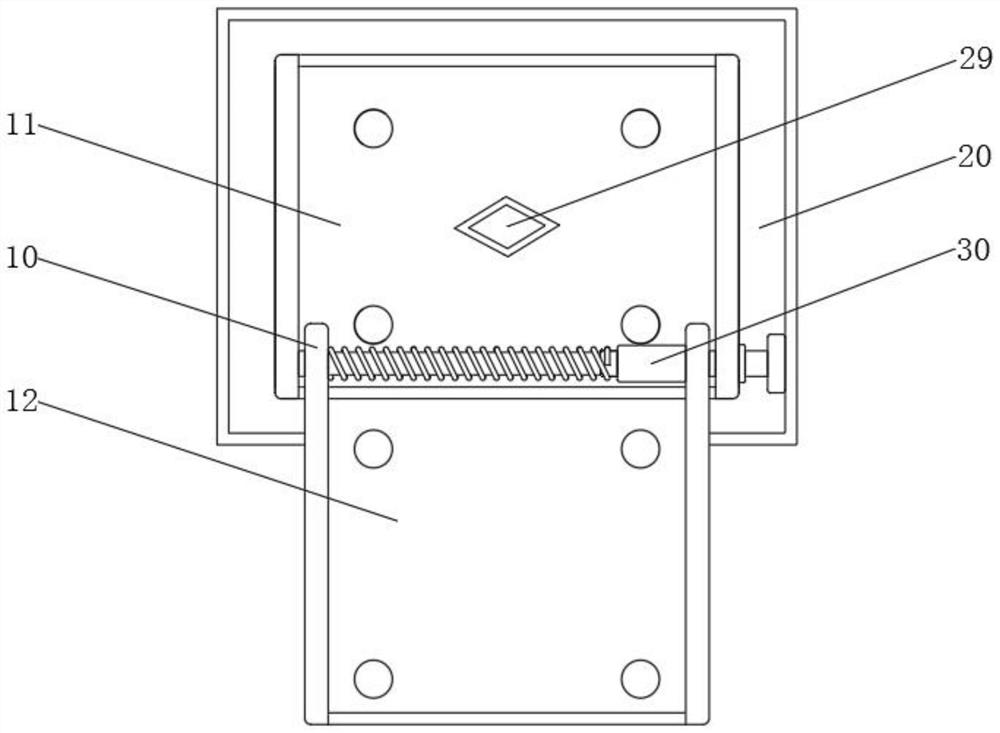

[0036] A kind of overturning mechanism with self-locking function, comprises overturning assembly 10, and overturning assembly 10 comprises fixed block 11, and the outer wall of fixed block 11 is fixedly connected to the inner side wall of mounting base 21 by the turntable 24 of installation, and one end of fixed block 11 Rotation is connected with turning block 12;

[0037] The interior of fixed block 11 is equipped with self-locking assembly 30, and self-locking assembly 30 comprises back-moving spring 31, and one end of back-moving spring 31 is fixedly connected with spring plunger 32, and one end of spring plunger 32 is fixedly connected with locking block 33, locking One side of the block 33 is fixedly connected with a push block 34, and one side of the push block 34 is slidably connected with a locking groove 35. One end of the locking groove 35 is provided with a circular hole, and the other end is provided with a curved hole smaller than the circular hole. Shaped hole ...

Embodiment 2

[0040] The installation function is added on the basis of the first embodiment.

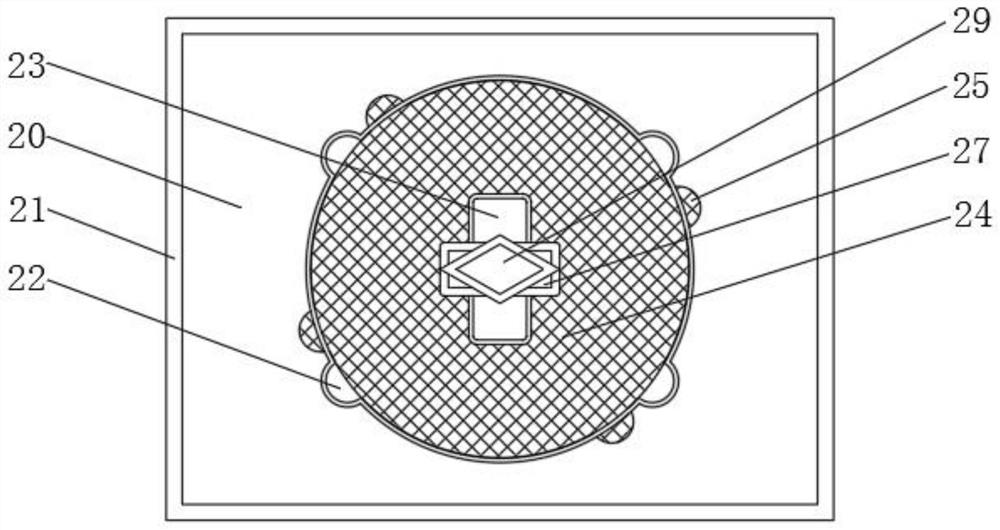

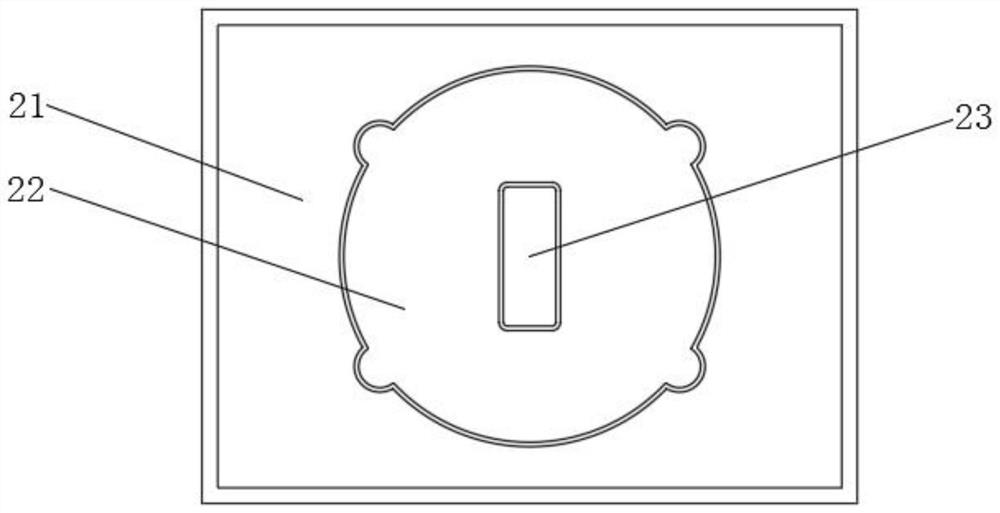

[0041] The outer wall of the fixed block 11 is provided with a mounting assembly 20, the mounting assembly 20 includes a mounting seat 21, the inner wall of the mounting seat 21 is provided with a mounting groove 22, and the middle part of the mounting groove 22 is provided with a limiting groove 23, and the limiting groove 23 is a kind of Rectangular slot, the limiting block 27 is a kind of rectangular block, the rectangular slot is longer than the rectangular block, the width of the rectangular slot is equal to the rectangular block, and one side of the limiting block 27 is clamped at the groove of the limiting slot 23 , the outer wall of the fixed block 11 is equipped with a turntable 24, the four vertices of the turntable 24 are respectively provided with a protrusion 25, the protrusion 25 is a semicircular protrusion, and the four vertices of the mounting groove 22 are respectively provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com