a hydraulic clutch

A clutch and hydraulic technology, applied in the direction of clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve problems such as drag pressure, slow drilling footage, and large frictional resistance, so as to reduce frictional resistance and improve drilling technology , Improve the effect of extension ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

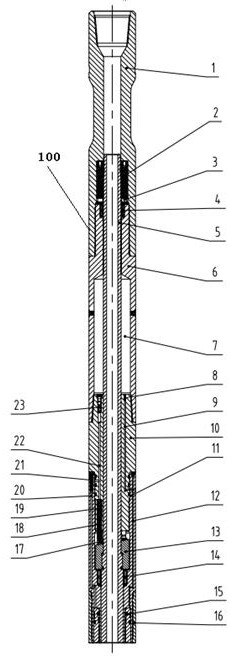

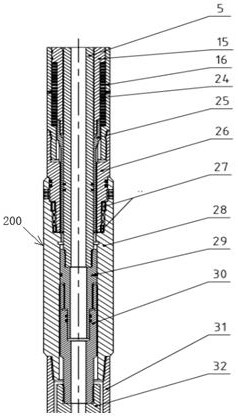

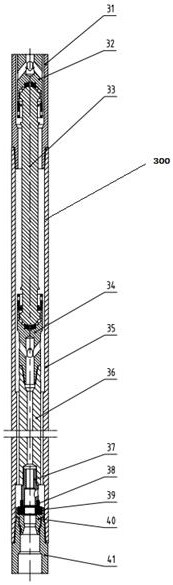

[0030] Example: as Figure 1 to Figure 14 As shown, a hydraulic clutch of the present invention includes a hydraulic oil pump assembly 100 connected in sequence, a mechanical meshing and disengaging assembly 200 controlled by hydraulic flow, a power assembly 300 and a counter torque assembly 400; The oil pump assembly 100 provides power, and uses the engagement and separation assembly 200 to control the power assembly 300 to rotate or not to rotate, and the reaction torque assembly 400 is used to overcome the reaction generated by the power drilling tool at the lower end of the hydraulic clutch. Rotational torque.

[0031] The hydraulic oil pump assembly 100 includes a hydraulic oil storage joint 6, one end of the hydraulic oil storage joint 6 is connected with the joint 1 on the casing, and the other end of the hydraulic oil storage joint 6 is connected with a swash plate pump cylinder joint. 10. The end of the swash plate pump cylinder joint 10 is threadedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com