Actuator assembly to maximize fatigue strength and mechanical durability and provide access protection

A technology of actuators and components, applied in mechanical equipment, engine components, transmission parts, etc., can solve problems such as shortening the service life of actuators and interfering with actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

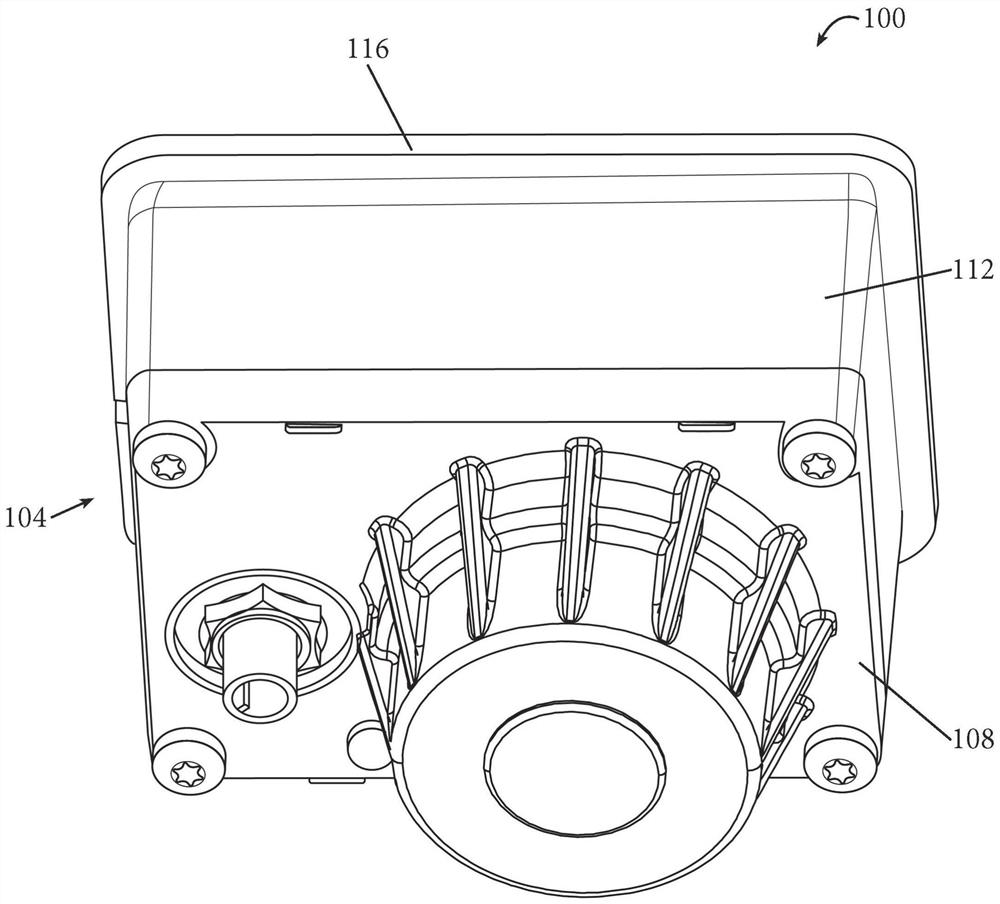

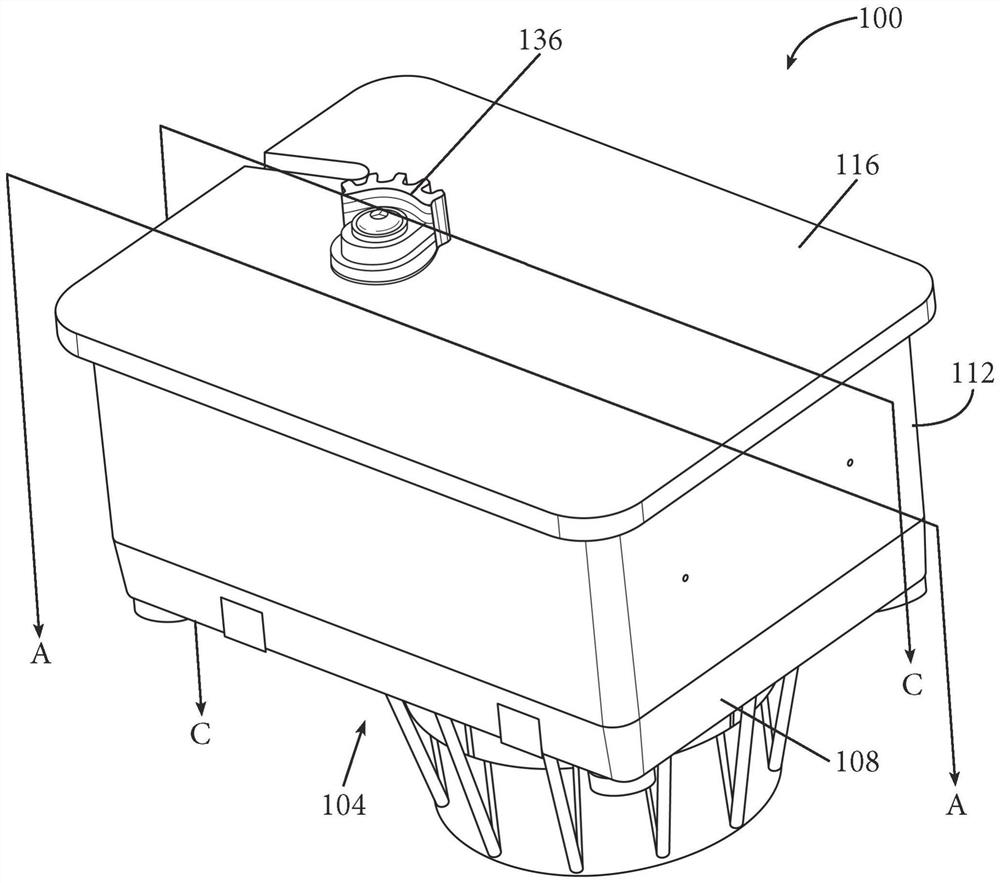

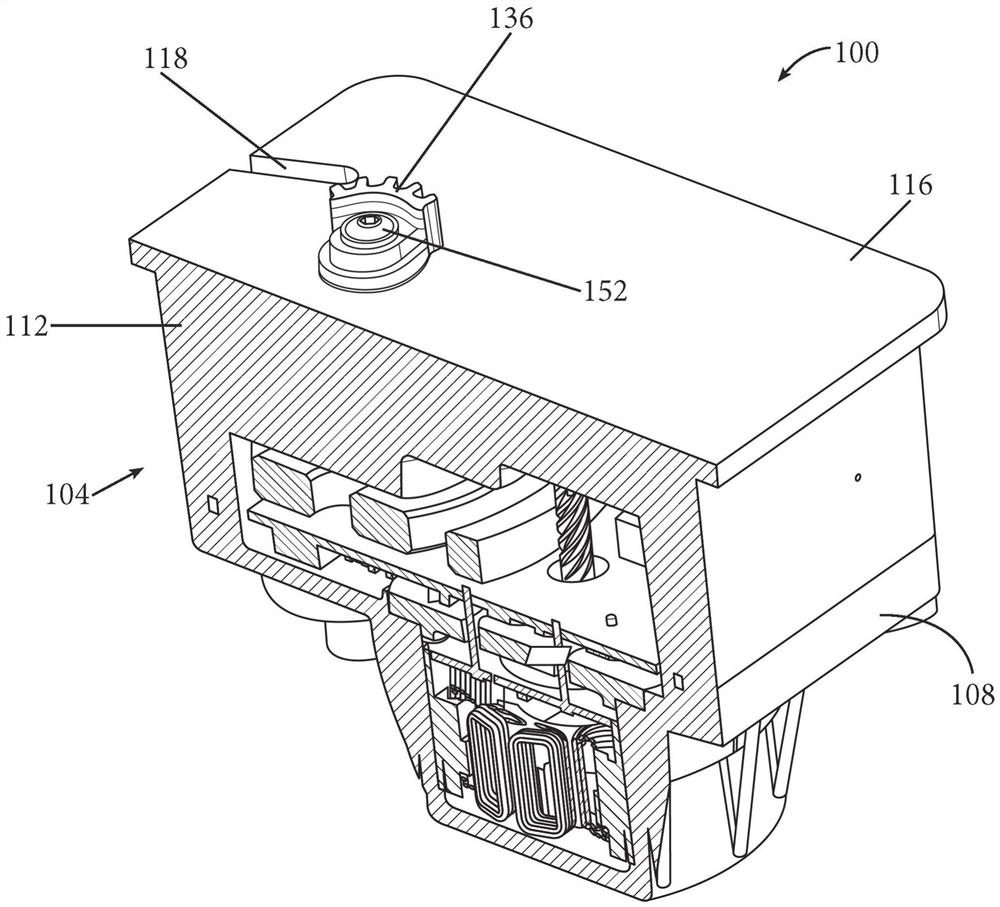

[0026] The present disclosure relates to actuator assemblies that maximize fatigue strength and mechanical durability and provide ingress protection against accidental fluid spills or splashes, such as in food and beverage applications, commercial vehicle applications, and other industrial applications. More specifically, the actuator assembly includes a drive gear configured to absorb forces applied to the drive gear (e.g., an external drive mechanism) during operation in a manner that maximizes the fatigue strength and mechanical durability of the drive gear. torsional load at a specific radial distance). For example, when a drive gear is operably coupled to an external drive mechanism (e.g., a rack and pinion, lever, link, or belt), the torsional load that the drive gear receives from the external drive mechanism is directed to a specific portion of the drive gear ( It has a higher strength than the rest of the drive gear). For example, the torsional loads that the drive g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com