Gear controller and gas plug valve

A gear shifter and controller technology, applied in the field of gas stoves, can solve problems such as inconvenient maintenance and gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

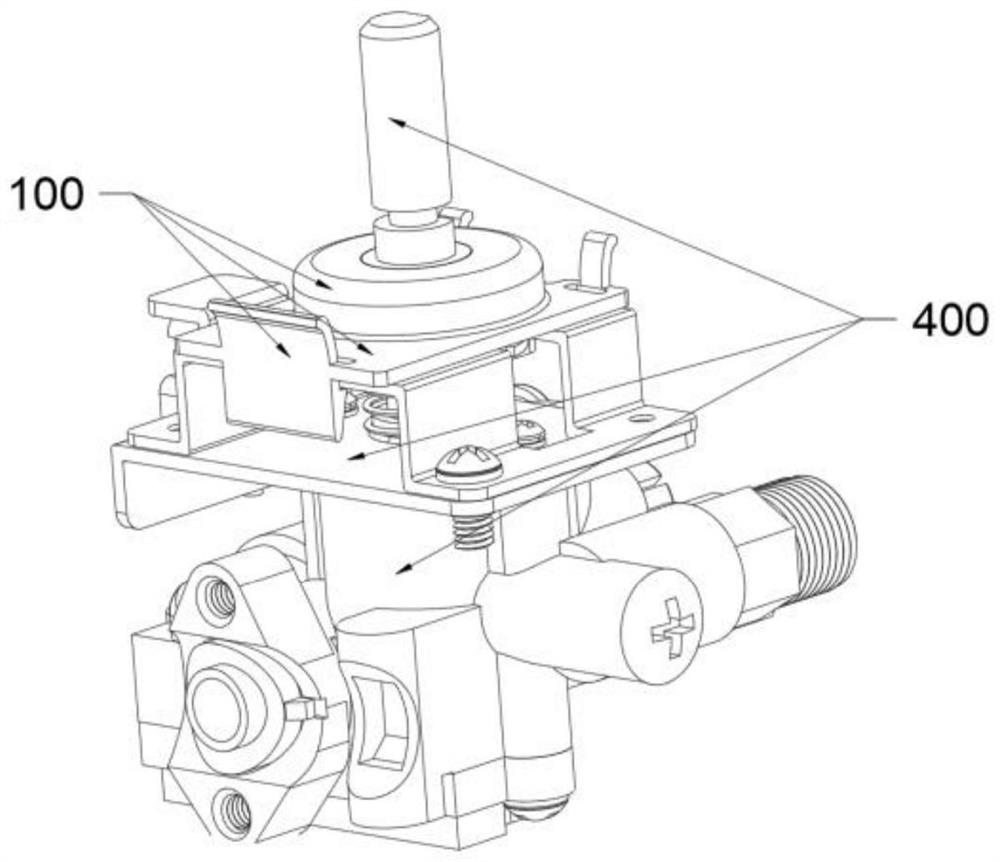

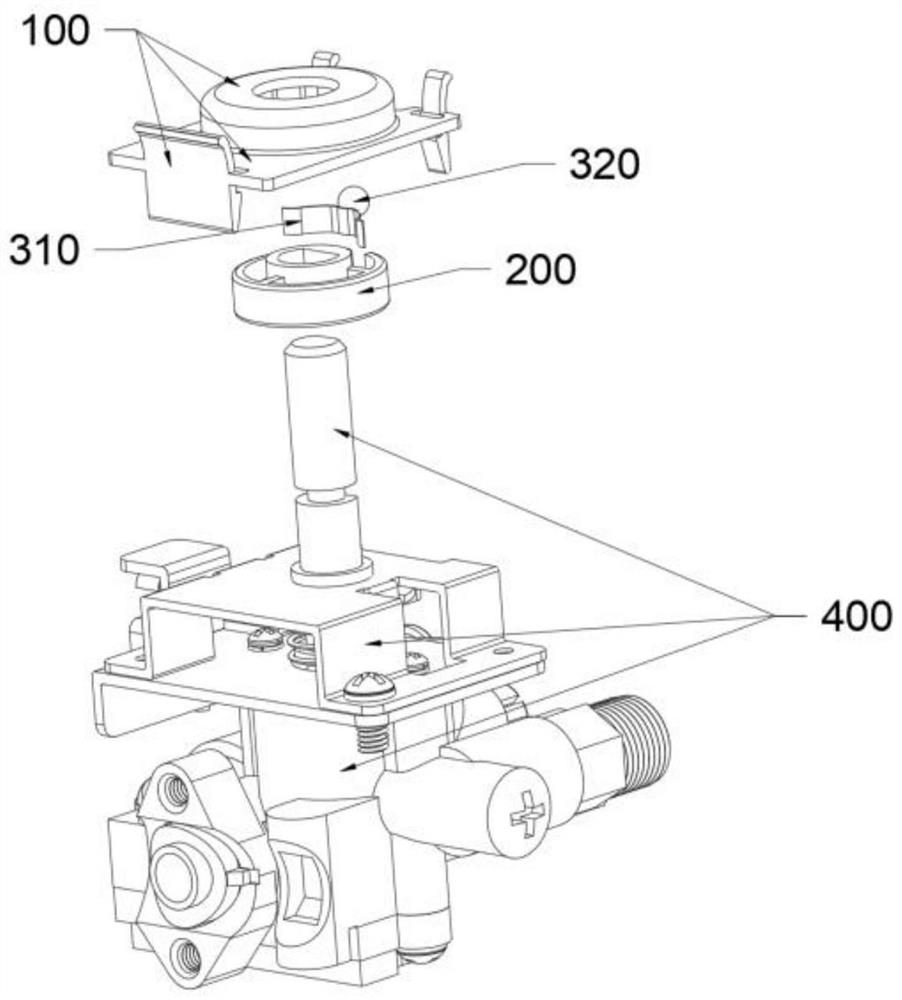

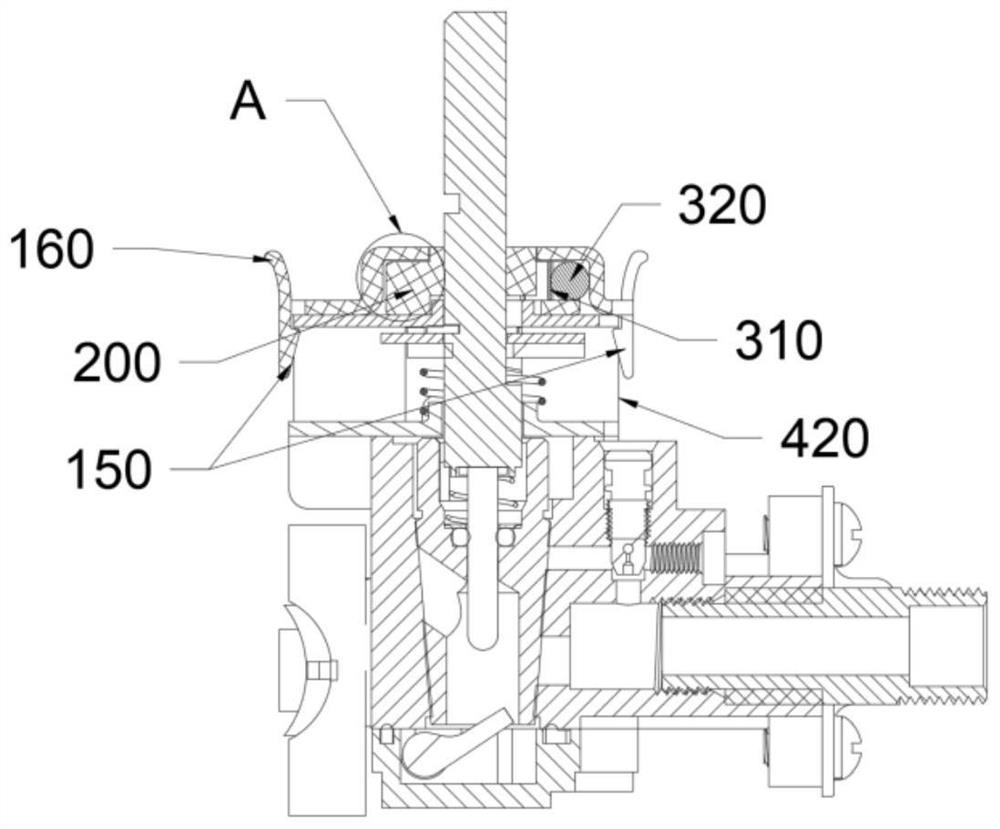

[0073] refer to Figure 1 to Figure 3 , the first embodiment provides a gear controller, the gear controller includes a gear cover 100 and a gear base 200; the gear cover 100 has a housing cavity, and the gear base 200 is located in the housing Inside, the shifter upper cover 100 and the shifter base 200 are provided with coaxial shaft holes, and the shifter base 200 can rotate relative to the shifter upper cover 100; the shifter upper cover 100 and the shifter base 200 A gear damping structure is provided between them, which is used to indicate that the base 200 of the gear shifter rotates at any damping position.

[0074] In specific use, the shaft hole is used to pass through the valve stem 410, and the valve stem 410 can drive the shifter base 200 to rotate relative to the shifter upper cover 100. During the rotation, due to the shifter upper cover 100 and the shifter A gear position damping structure is provided between the positioner bases 200, which can instruct the po...

Embodiment 2

[0093] refer to Figure 9 to Figure 12 , the second embodiment also provides a gear controller, which differs from the first embodiment in that:

[0094] The gear elastic mechanism includes an elastic spherical portion 330 protruding from the outer peripheral side of the gear shifter base 200 and capable of abutting against the gear arc surface groove 120 .

[0095] Specifically, the gear elastic mechanism is integrally injection molded with the gear bottom 200; the gear base 200 includes a base body 220 and a first boss 230 and a second boss 240 protruding from one side of the base body 220, An annular space is formed between the first boss 230 and the second boss 240; the through hole corresponding to the boss is opened in the first boss 230, and the shaft hole clearance between the first boss 230 and the shifter upper cover 100 is 10 Matching; the second boss 240 is provided with a notch 241 communicating with the annular space, and the elastic spherical portion 330 of the...

Embodiment 3

[0098] refer to Figure 1 to Figure 12 , the present embodiment 3 provides a gas cock valve, the gas cock valve includes a valve body 400, a valve core 500 and the gear controller of the aforementioned embodiment 1 or embodiment 2; the valve body 400 includes a valve stem 410 and a valve cover 420 The valve core 500 is installed in the valve body 400, the valve stem 410 is connected with the valve core 500, and can drive the valve core 500 to rotate relative to the valve body 400; ; The shifter upper cover 100 is installed on the valve cover 420 .

[0099] Wherein, the shifter base 200 is fixedly sleeved on the valve stem 410 through the second shaft hole 210, the aperture diameter of the first shaft hole 110 is larger than the aperture diameter of the second shaft hole 210, and the first shaft hole 110 and the shifter base 200 The first boss 230 is clearance fit;

[0100] In this embodiment, the shifter upper cover 100 is locked on the valve cover 420 through the elastic bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com