Device and method for detecting color uniformity of three-color polyester

A detection device and a technology for uniformity, applied in the field of computer colorimeters, can solve the problems such as the influence of the correctness of the measurement, the high price, and the influence of the correctness of the measurement, and achieve the effect of accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

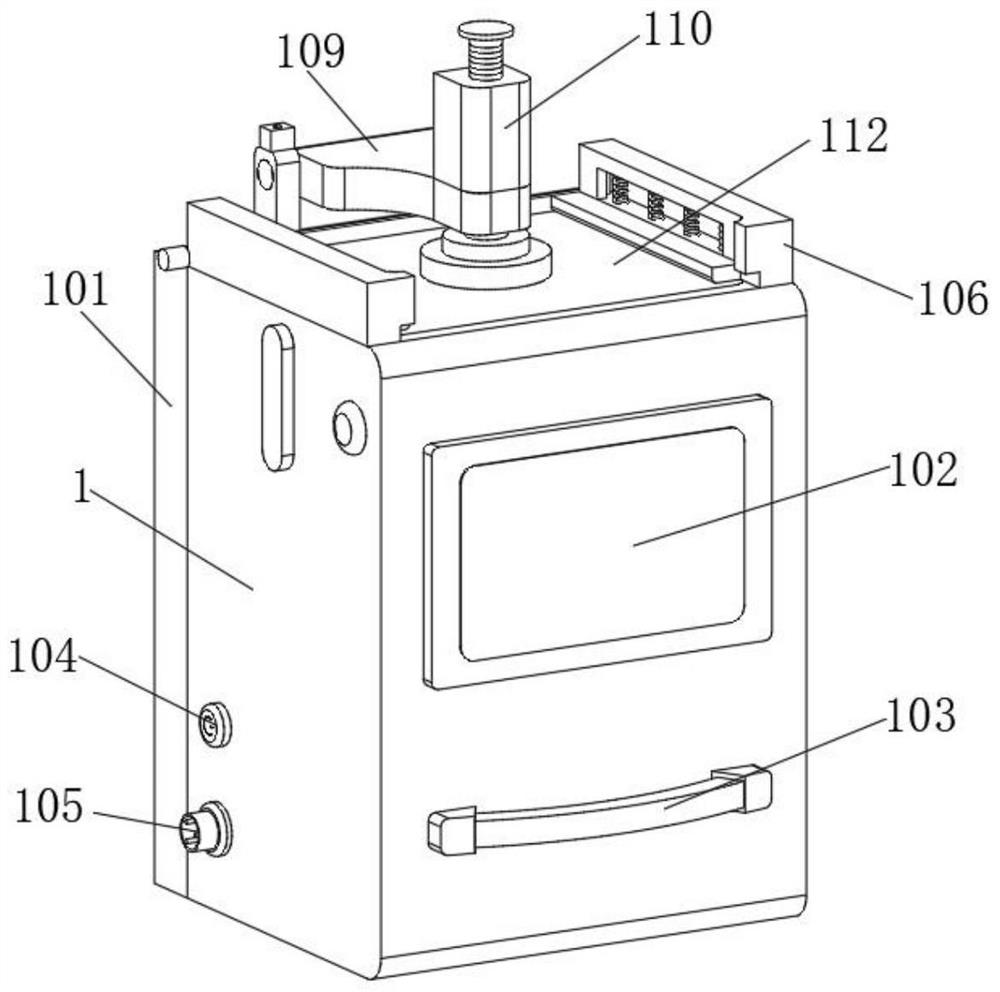

[0034] The embodiment of the present invention discloses a three-color polyester color uniformity detection device,

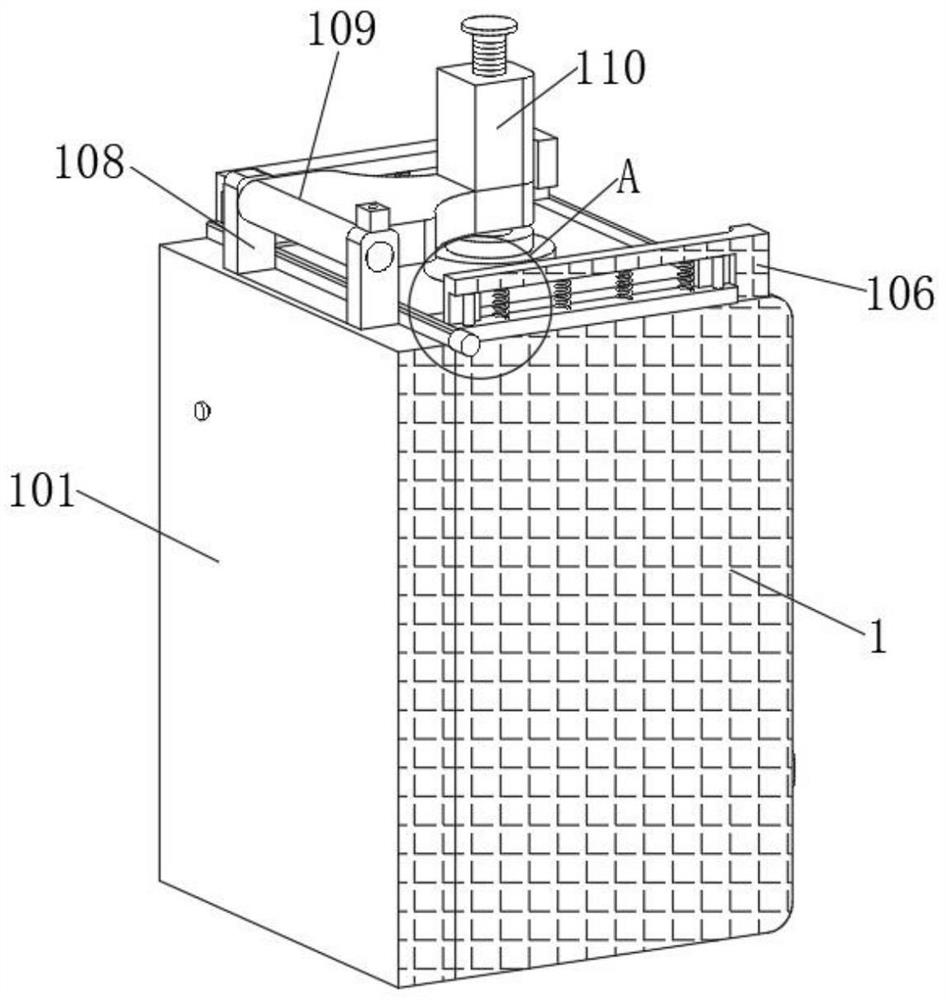

[0035] Such as figure 1 and figure 2 As shown, it includes a tester main body 1, the back of the tester main body 1 is fixedly connected with a fixing seat 101, the front of the tester main body 1 is provided with a display 102 and a handle 103, and the side of the tester main body 1 is provided with a switch 104 and a plug port 105 , the upper surface of the tester main body 1 is fixedly connected with two connecting seats 106, the upper surface of the tester main body 1 is provided with an inlet whiteboard 112, and an extruder 113 is arranged directly above the inlet whiteboard 112;

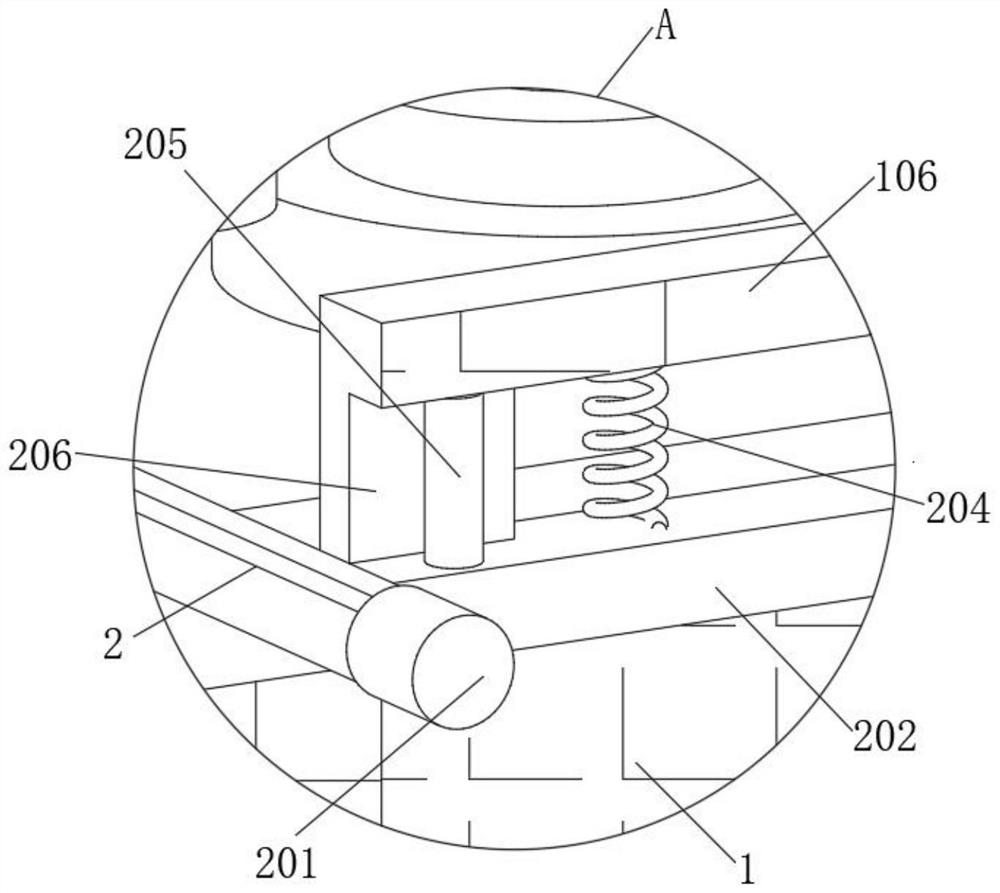

[0036] The inner wall of the fixed base 101 is slidably connected with a movable base 107, and the upper surface of the movable base 107 is fixedly connected with two supporting bases 108, and a rotating block 109 is connected between the two supporting bases 108, and the uppe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap