Backward centrifugal fan and design method thereof

A centrifugal fan and fan technology, applied in mechanical equipment, liquid fuel engines, pumps, etc., can solve the problems of noise, backward centrifugal fan boundary layer separation, backward centrifugal fan shedding vortex, etc., to reduce fan noise and reduce separation. Vortex and trailing edge shedding vortex, the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further explained in the form of specific examples below. The following examples are only preferred modes of the present invention, and the desired technical effects of the present invention can be achieved within the scope of the present invention.

[0025] A kind of backward centrifugal fan, is made up of wheel bottom, wheel cover and fan blade between them, and described fan blade is divided into altogether 6 planes from wheel bottom to wheel cover and constitutes (such as Figure 13 ), define the plane at the bottom of the wheel as the first plane.

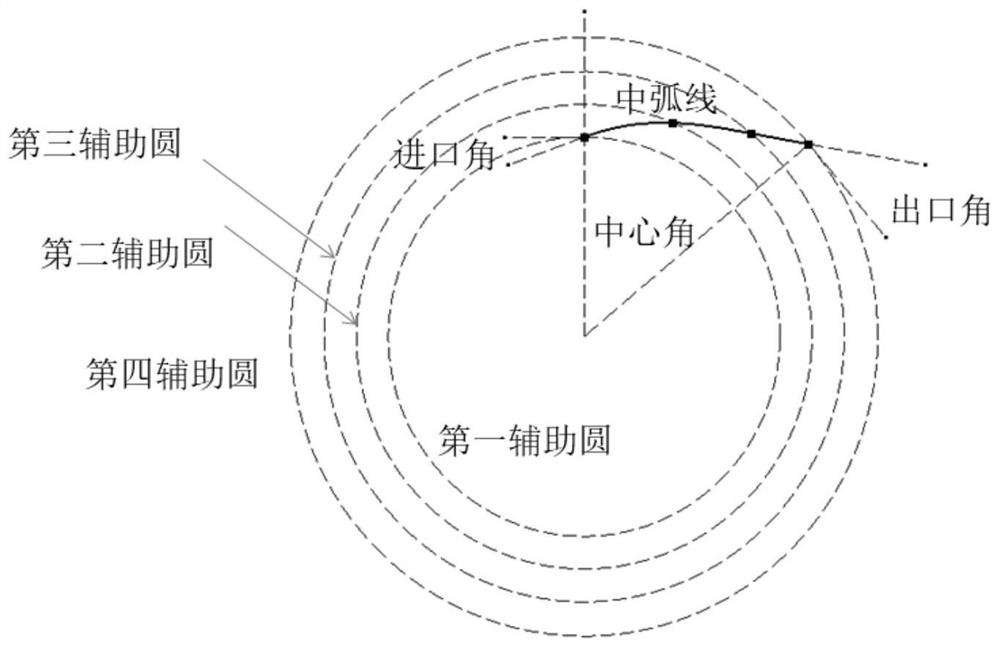

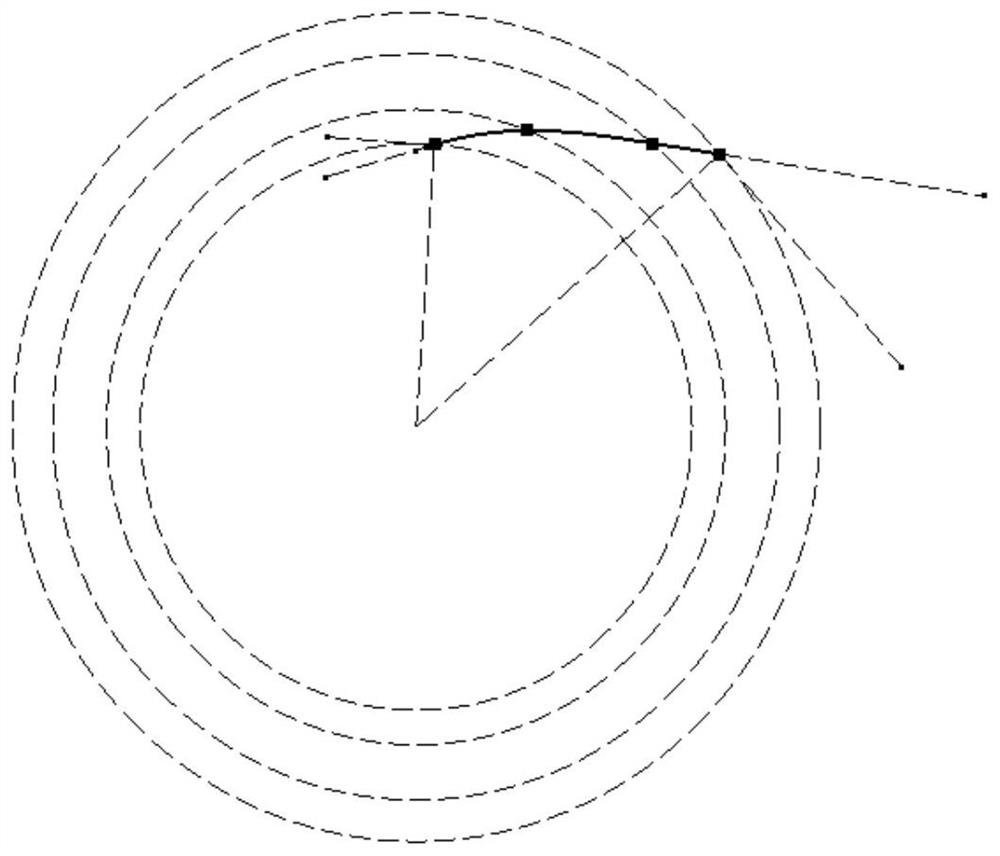

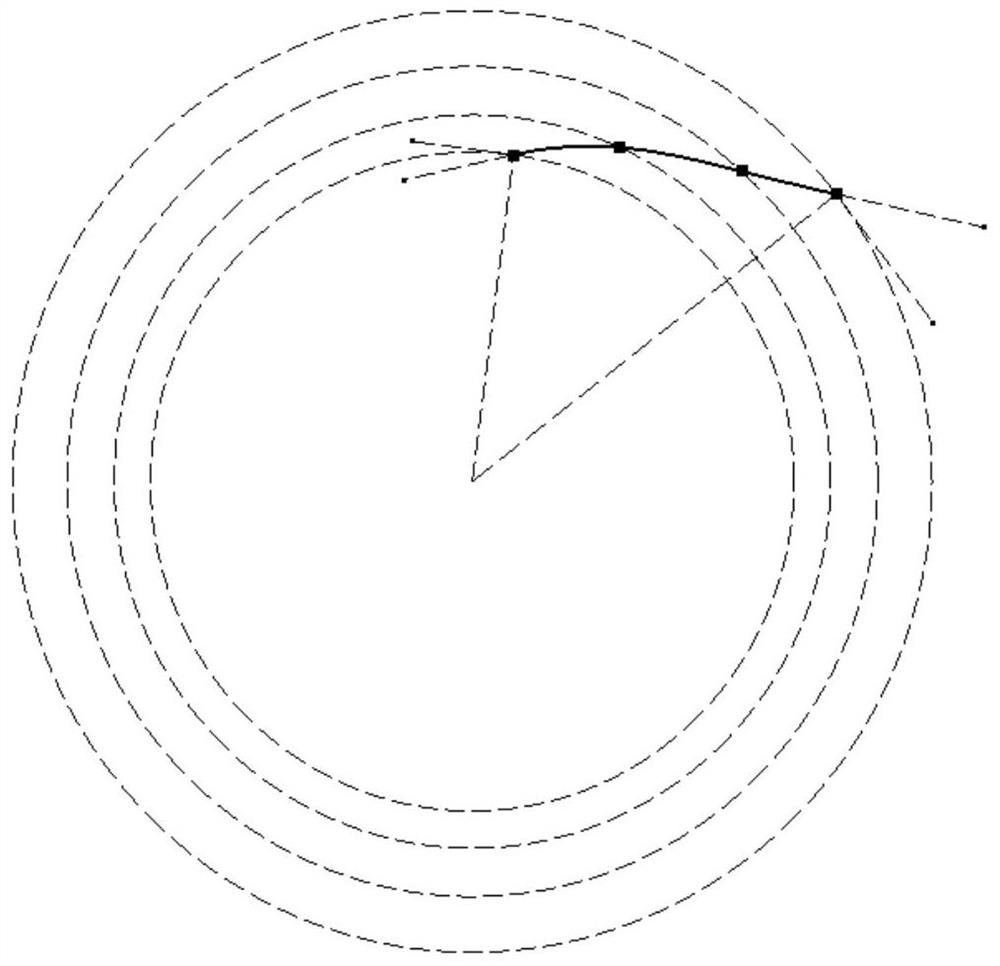

[0026] The fan blade intersects the plane to obtain the fan blade airfoil. The fan blade airfoil includes a central angle, an inlet angle, an outlet angle, and a middle arc. The middle arc of each fan blade airfoil is assisted by 4 circles. Lines are drawn, and the mid-arc is set as a spline during the design process. The circle where the starting point of the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com