Biological interface for planting seaweed

A biological and interface technology, applied in plant cultivation, seaweed cultivation, botanical equipment and methods, etc., can solve problems such as limited improvement of surface texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

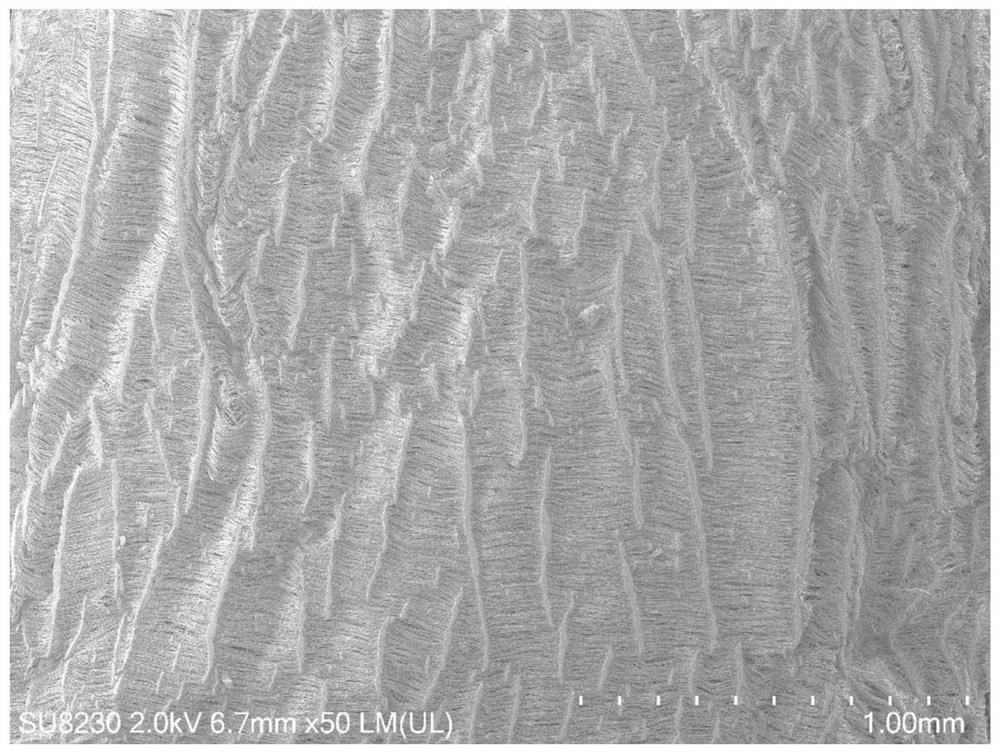

[0176] Example 1 - Porous Polyethylene

[0177] Dulse and kelp culture experiments were carried out on two kinds of porous polyethylene-based membranes.

[0178] Membrane 1 is a gel-treated polyethylene membrane with a width of 500 mm and a thickness of 30 μm with an areal density of 18.1 g / m 2 , the porosity is about 36%. Subsequently, the tape was stretched in the machine direction with a stretch ratio of 2:1 and a stretch rate of 4.3% / sec through a hot air dryer set at 120 degrees Celsius. Then it was stretched in the transverse direction at a ratio of 4.7:1 in an oven at 130°C, and the stretching rate was 15.6% / sec. According to the ASTM D412 test, the resulting film has the following characteristics: width 697 mm, thickness 14 microns, porosity 66%, maximum load in machine direction and transverse direction 7.65 N x 6.23 N, elongation at maximum load, respectively is 25.6% x 34.3%. The Gurley Time of the film was 15.7 seconds. The Gregorian time is defined as the num...

Embodiment 2

[0183] Example 2 - Patterned Film

[0184] According to certain embodiments, a patterned fluoropolymer-based membrane is produced with large square regions of low porosity and high porosity. The pattern is in the form of a "checkerboard" design.

[0185] Film samples were mounted on 2 inch diameter PVC cups. All samples were sprayed with alcohol and rinsed with fresh water before sowing. Seeding is accomplished by pouring the spore solution over the sample and allowing the spores to settle to the substrate surface. Samples were seeded in 10 gallon tanks with weekly seawater changes. After week 2, dulse samples were transferred to 40 gallon fiberglass tanks. Kelp samples were grown in 10 gallon tanks. All cultures were aerated. Samples were taken when plants were visible 2 months after sowing.

[0186] All dulse samples were rinsed gently with fresh water and then immersed in seawater prior to evaluation to remove any dirt. refer to Figure 16 , the checkerboard patter...

Embodiment 3

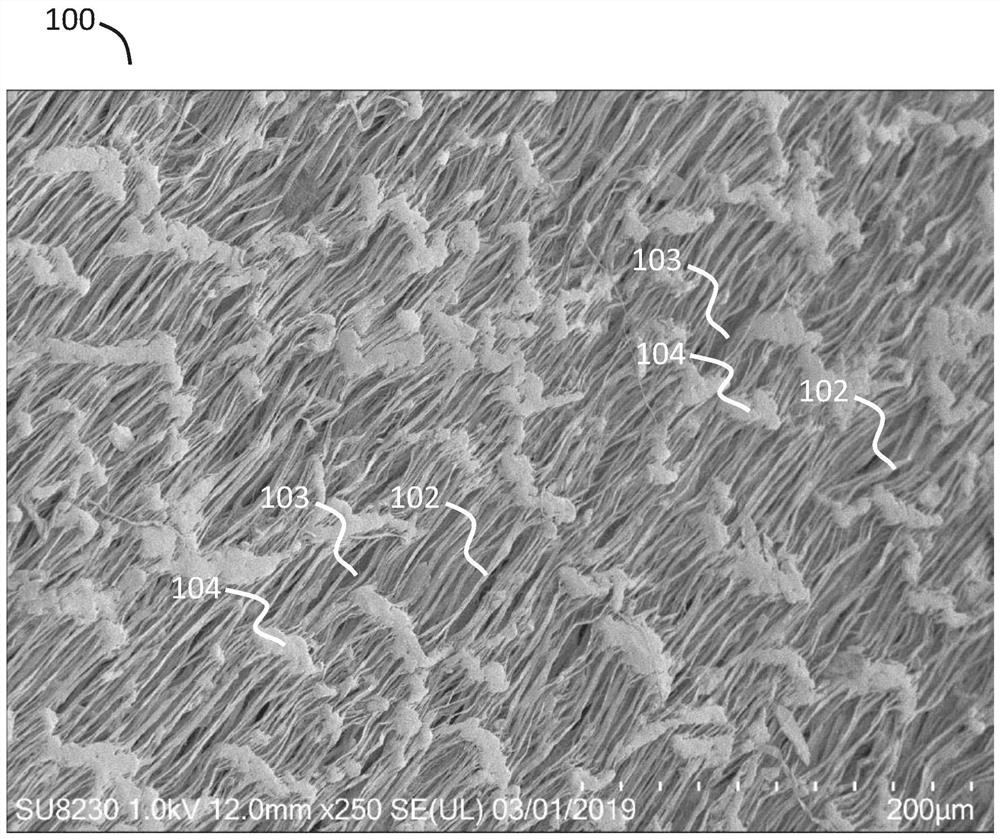

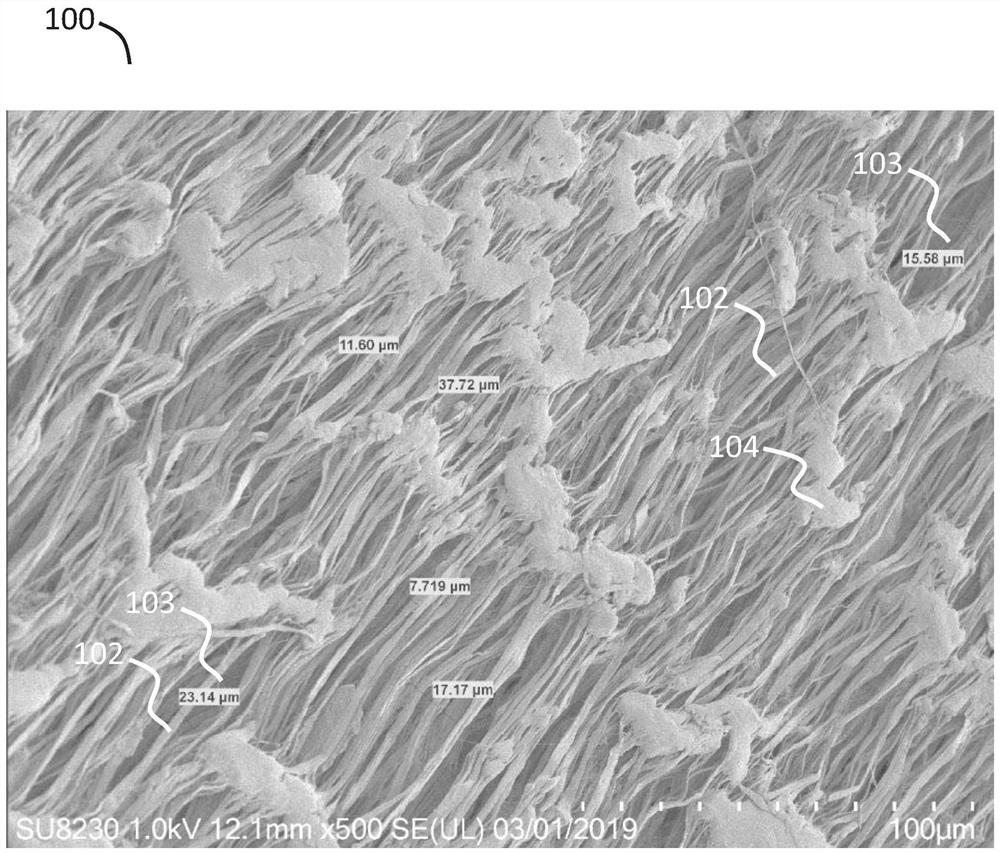

[0188] Example 3 – Direct sporophyte seeding

[0189] Laminaria sporozoites previously under induction conditions were seeded without any binder onto experimental membranes of the present disclosure with a width of 4 mm and a braided polyester control with a diameter of 2 mm. Attachment of juvenile sporophytes was assessed 19 days after sowing. It was demonstrated that sporophytes attach and grow on both substrates. Figure 18 Shows healthy sporophyte growth on membranes of the present disclosure.

[0190] To quantify the strength of attachment to the two substrates, 20 or more sporophytes attached to each substrate were scored on a scale of 1 to 5, where 1 indicates very weak attachment and 5 indicates very strong attachment. Most of the sporophytes attached to the woven polyester control were rated as "1" with very weak attachment. Most of the sporophytes attached to the experimental membranes were rated as "5" for very strong attachment. The difference in attachment str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area density | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap