Environment-friendly rust-proof device for hardware products

An environmentally friendly, product technology, which is applied to devices, cleaning methods and utensils for coating surfaces, and cleaning methods using tools, etc. hassle, avoids wastage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

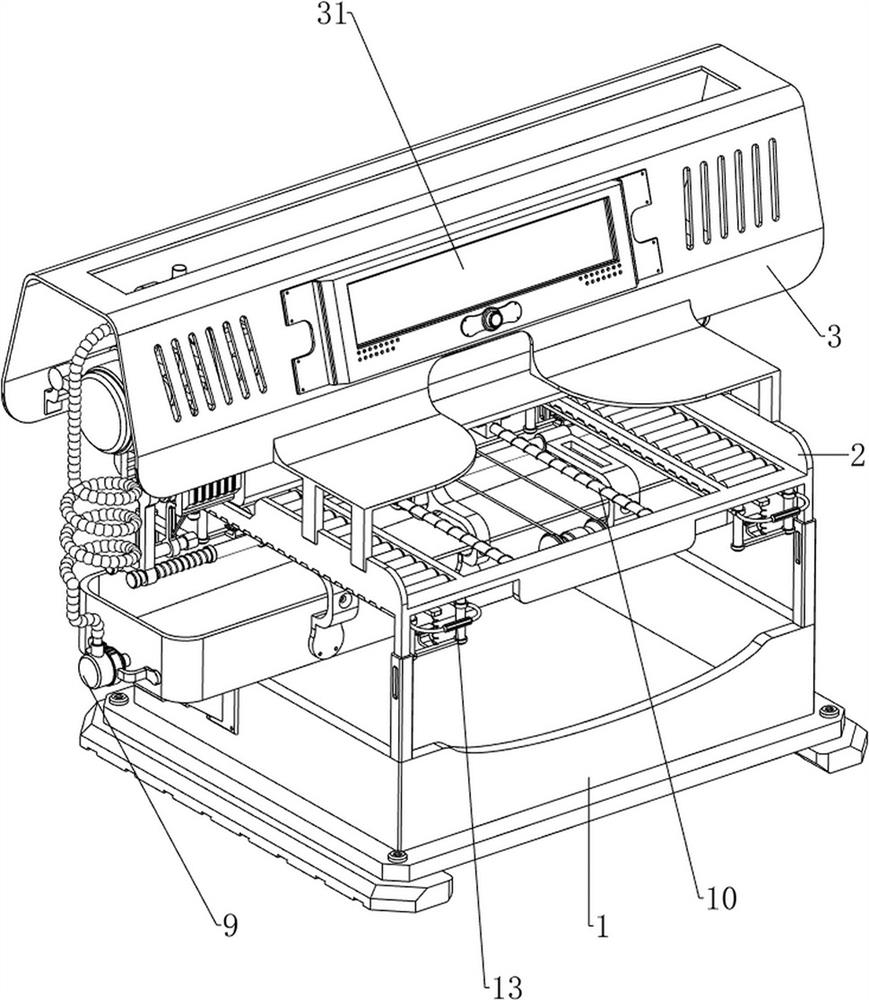

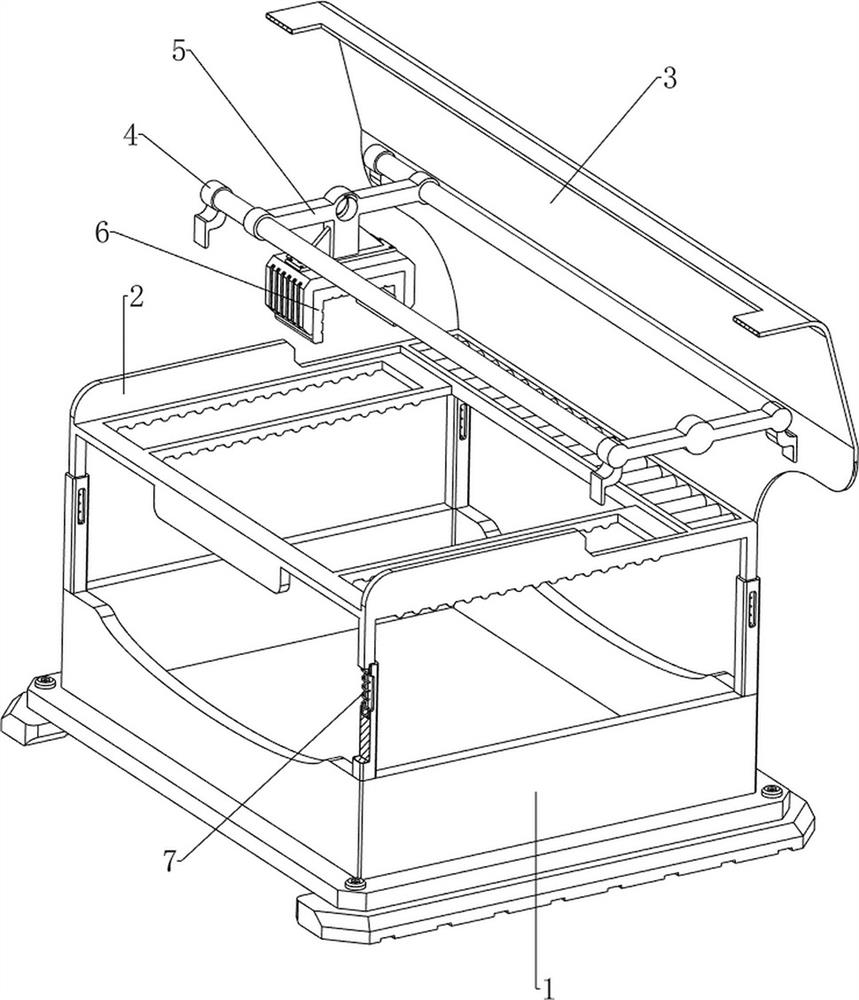

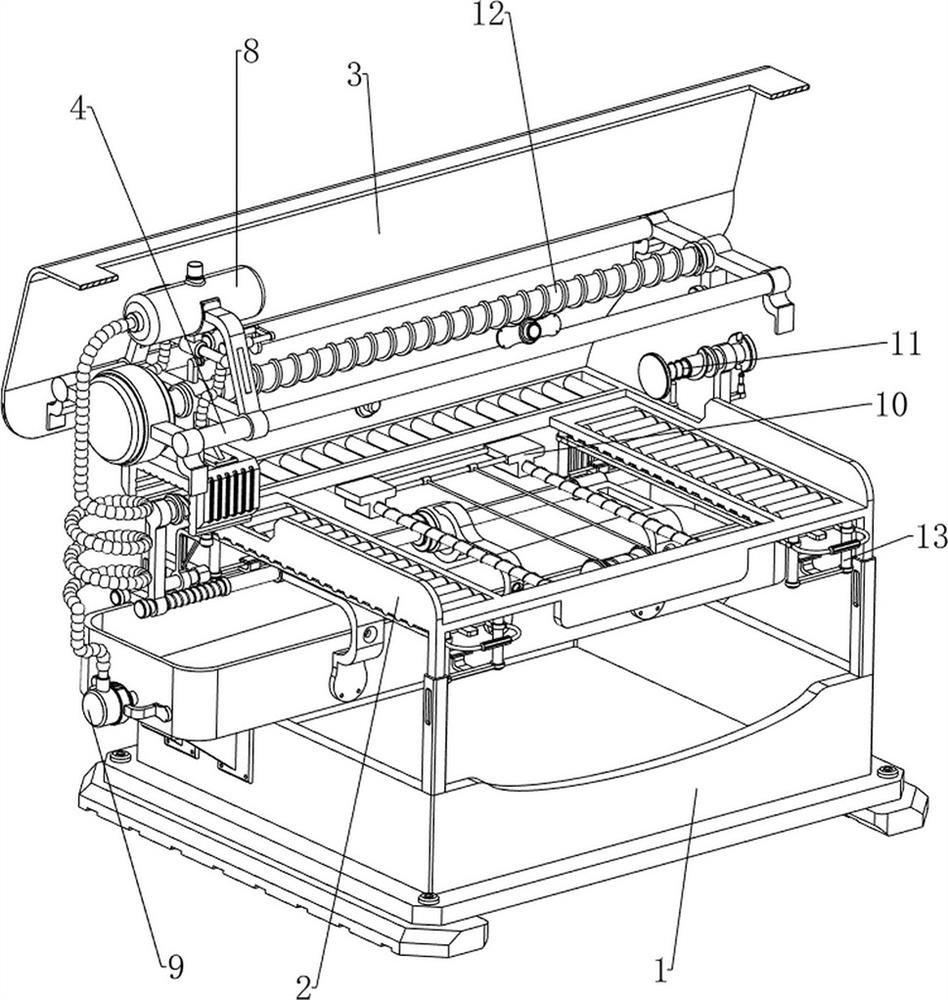

[0039] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 16 and Figure 17 As shown, an environment-friendly antirust device for hardware products includes a base 1, a first sliding block 2, a frame body 3, a control box 31, a fixed sliding bar 4, a second sliding block 5, a sponge block 6, a first Spring 7, unloading mechanism 8 and circulation mechanism 9, base 1 top sliding type is provided with first sliding block 2, and first sliding block 2 top is provided with frame body 3, and frame body 3 front side middle is provided with control box 31, controls A switching power supply, a power supply module and a control module are installed in the box 31. The switching power supply supplies power to the environment-friendly antirust device for the entire hardware product. The output end of the switching power supply is electrically connected to the power supply module. The switch, the power module and the control module are elec...

Embodiment 2

[0044] like figure 1 , image 3 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, on the basis of Embodiment 1, a feeding mechanism 10 is also included, and the feeding mechanism 10 includes a touch switch 101, a first slide bar 102, a roller 103, a fifth bracket 104, a first biaxial motor 105, reel 106, stay cord 107, second spring 108, connecting rod 109 and electromagnet 1010, control box 31 front side lower middle is fixedly connected with touch switch 101 by screw, touch switch 101 and control module pass electric Two first sliding rods 102 are arranged in the upper middle of the first sliding block 2, rollers 103 are evenly spaced on the left and right sides of the upper part of the first sliding block 2, and the front and lower sides of the upper part of the first sliding block 2 are fixed by bolts There is a fifth bracket 104, the rear side of the fifth bracket 104 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com