A kind of equipment for easy and quick loading and unloading of perforated bricks

A technology of porous bricks and equipment, applied to multi-axis trolleys, transportation and packaging, sleds, etc., can solve the problems of porous brick damage, loading pocket shaking, time-consuming and labor-intensive problems, and achieve the effects of saving time, improving efficiency, and avoiding sloshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

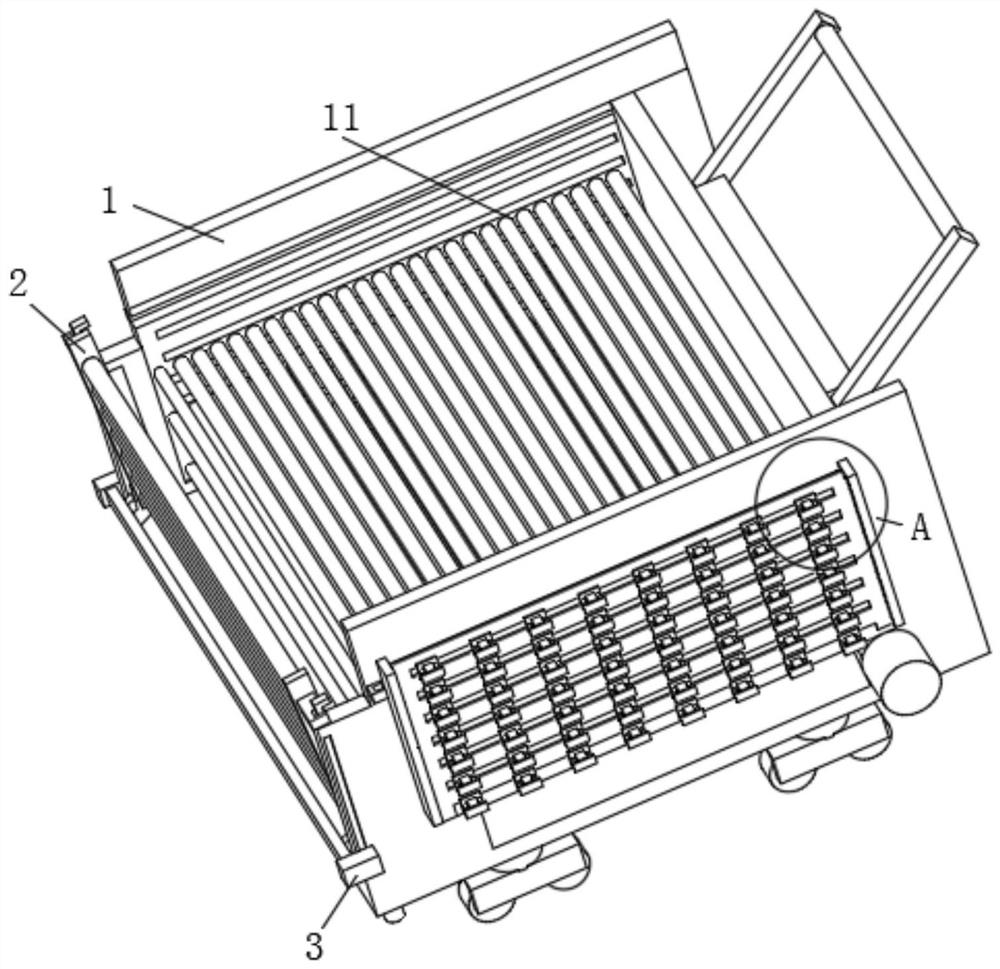

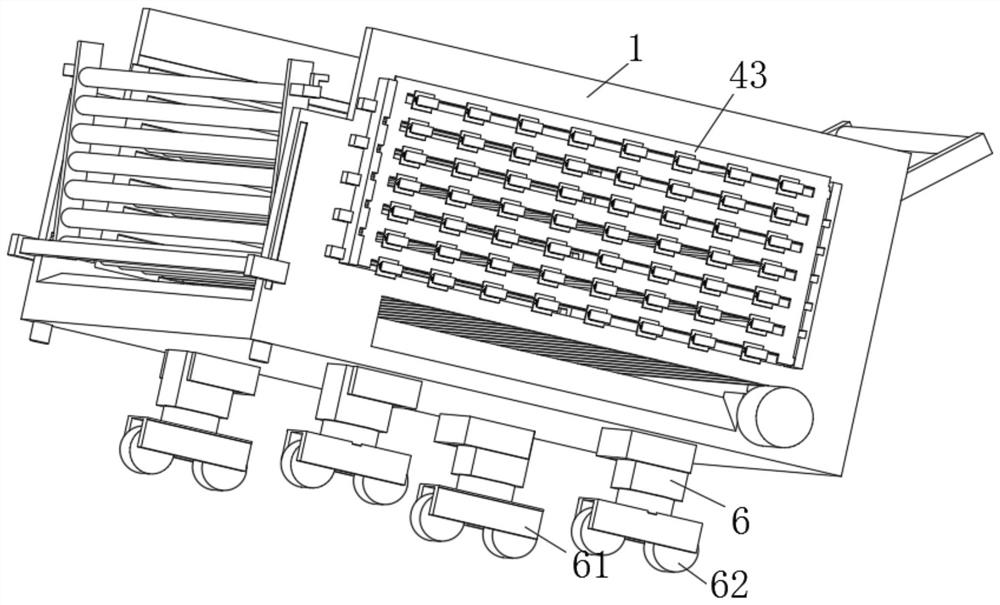

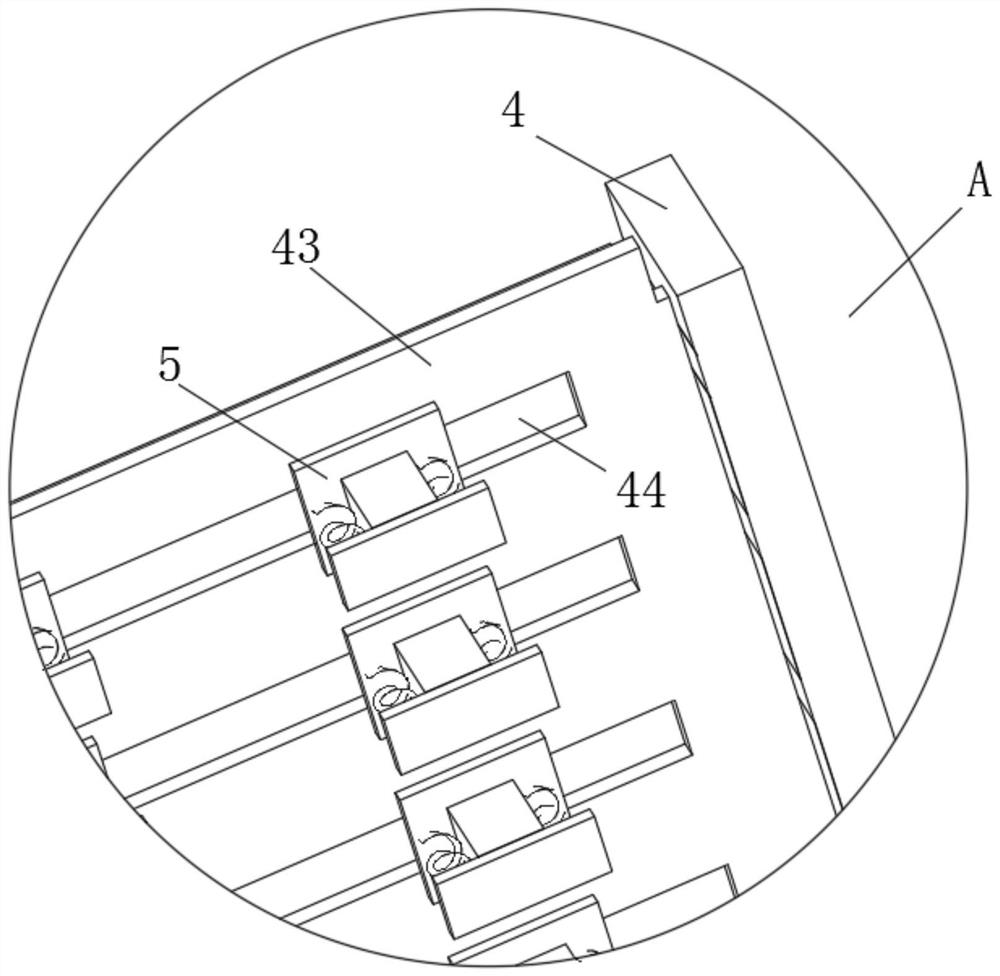

[0031] like Figure 1-Figure 9 As shown in the figure, a perforated brick device that facilitates quick loading and unloading includes a loading pocket 1, and a multi-layer rotating column 11 is rotated between the inner side walls of the loading pocket 1. The pillars 11 are arranged in parallel, and one end of the side wall of the loading pocket 1 is provided with an adjustment groove. An adjustment threaded rod 71 is rotatably connected between the part and the bottom of the adjustment groove. The two side walls of the groove are slidably connected, and the side of the adjusting block 72 away from the inner wall of the adjusting groove is provided with a mounting hole 73 , and the adjusting rotating column 22 is rotated in the mounting hole...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap