Prefabricated wallboard convenient to install

A technology of prefabricated wall panels and assembled panels, which is applied in the direction of lighting and heating equipment, building components, fixed conduit components, etc. It can solve the problem of inability to assist the temperature adjustment of the chicken house, prefabricated wall panels are inconvenient to install and disassemble, and affect the installation of the chicken house Various equipment and other issues, to achieve the effect of convenient assembly and use, structural optimization, rapid assembly and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

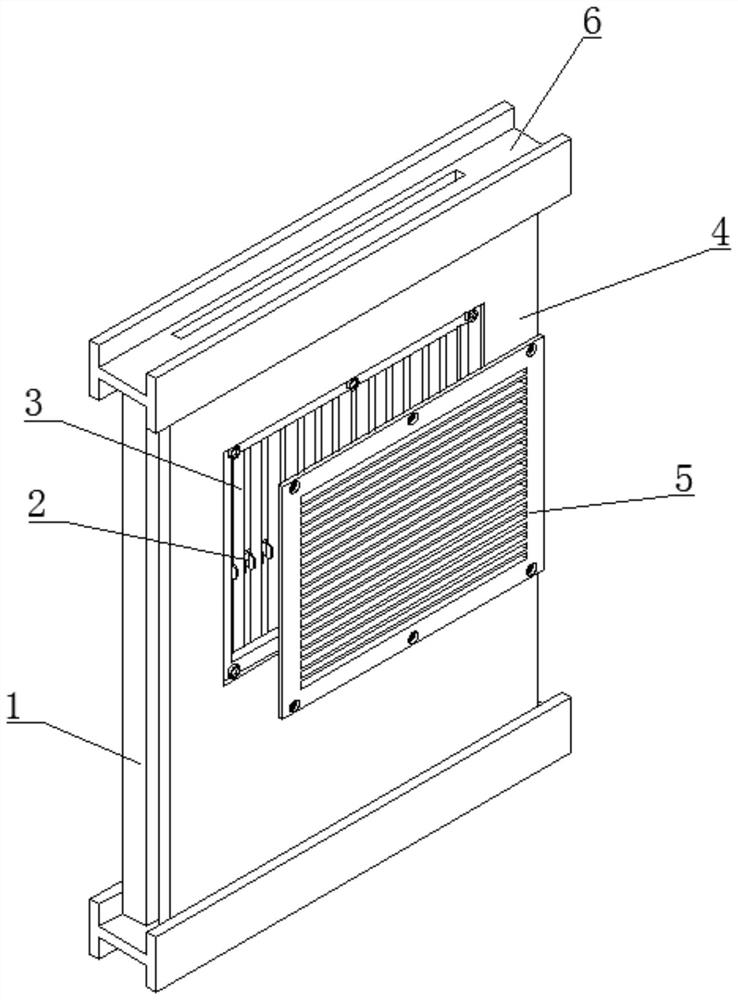

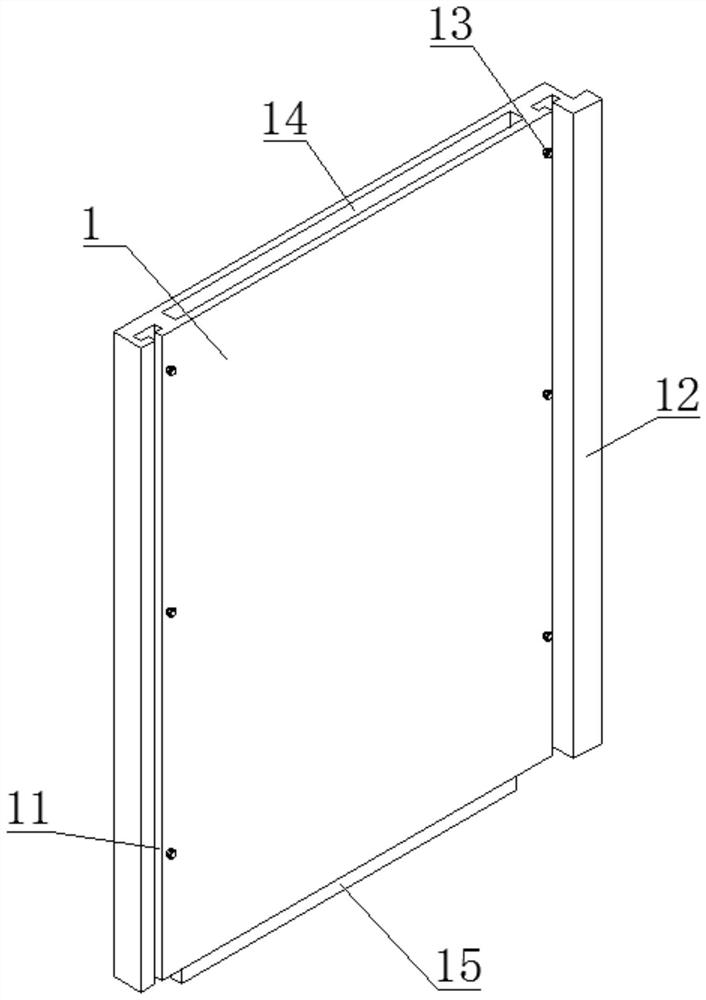

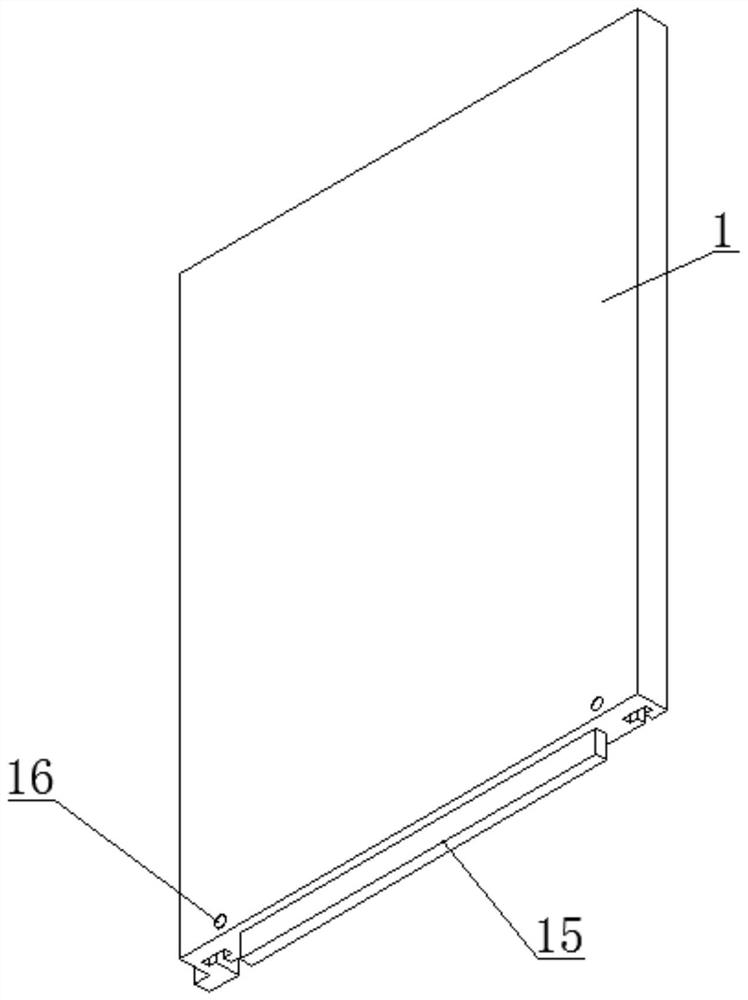

[0027] Example: refer to figure 1 Shown: a prefabricated wall panel that is easy to install, including a first assembly plate 1, a number of clamping plates 2 are installed on the front of the first assembly plate 1 from top to bottom, and a second assembly plate is clamped on the front of the first assembly plate 1 3. A heat exchange coil 4 is installed between the first assembly plate 1 and the second assembly plate 3, and the heat exchange coil 4 is stuck on the card plate 2. The upper part of the second assembly plate 3 is provided with a heat dissipation frame 5, and the first Assembly plate 1 and second assembly plate 3 top and bottom are all provided with cross bar 6; It is convenient to fix the heat exchange coil 4 and facilitate the stable operation of the heat exchange coil 4. The second assembly plate 3 is convenient to shield the heat exchange coil 4, which not only protects the heat exchange coil, but also increases the strength of the wall to dissipate heat. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com