Blue light scanning part integration detection tool and part quality evaluation method

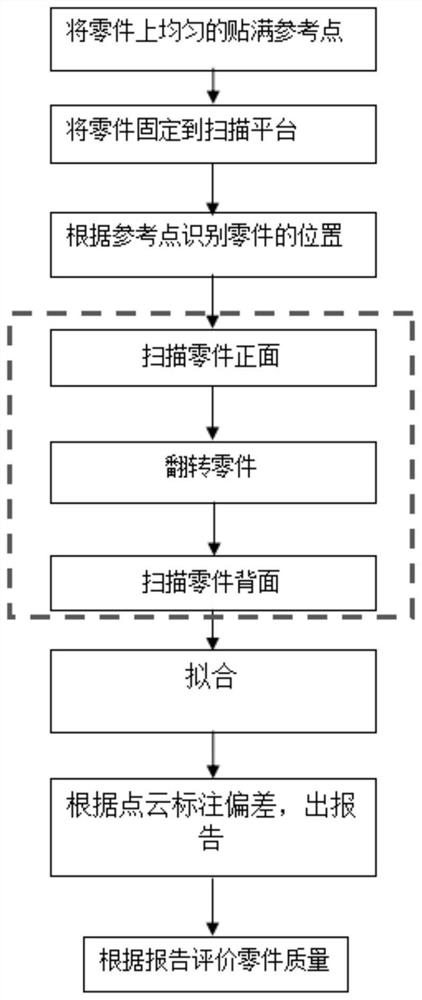

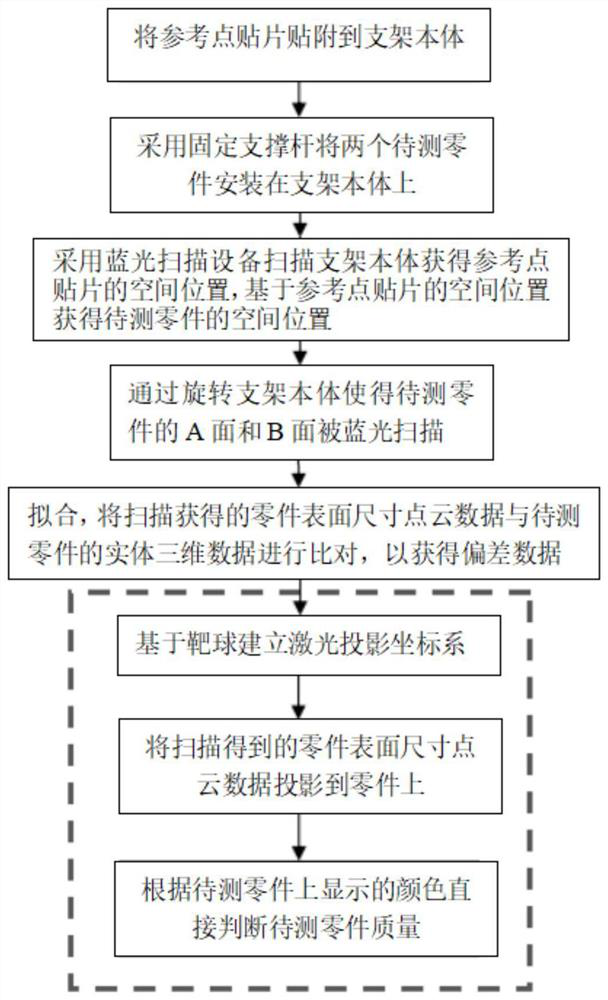

A technology that integrates inspection and parts, and is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means. It can solve problems such as high employee skill requirements, low work efficiency, and high labor costs. Convenient and fast, avoid repeated pasting, high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The blue-ray scanning part integrated detection tool and part quality evaluation method described in the present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments. However, the explanation and description do not constitute an improper limitation on the technical solution of the present invention.

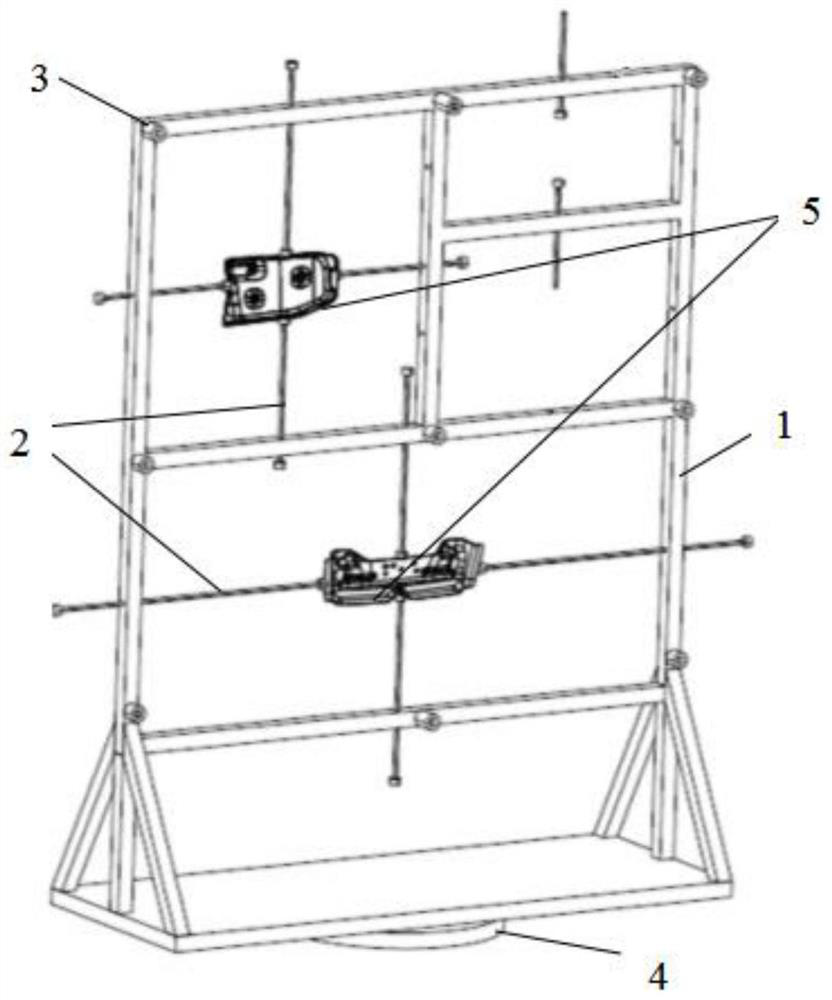

[0054] figure 2 It is a structural schematic diagram of an integrated detection tool for blue-ray scanning parts in an embodiment of the present invention.

[0055] like figure 2 As shown, in this embodiment, the integrated inspection tool for blue light scanning parts of the present invention may include: a bracket body 1 , a fixed support rod 2 , several target ball positioning posts 3 and a base 4 . Wherein, the bracket body 1 can be arranged on the base 4 through a rotating shaft (not shown in the figure), and the bracket body 1 can rotate around an axis extending along the height direction th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com