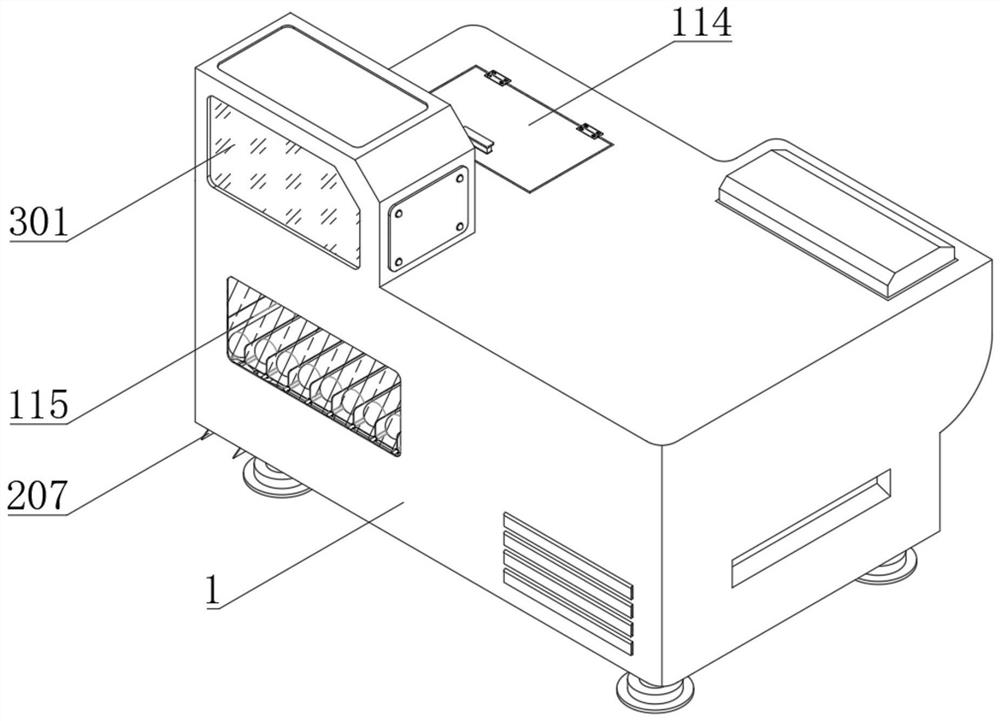

Self-service full-automatic roast sausage vending machine

A vending machine and fully automatic technology, which is applied in the field of sausage roasting machines, can solve the problem that customers need to wait for salesmen to buy sausages, and achieve the effects of saving labor intensity, reducing waiting time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

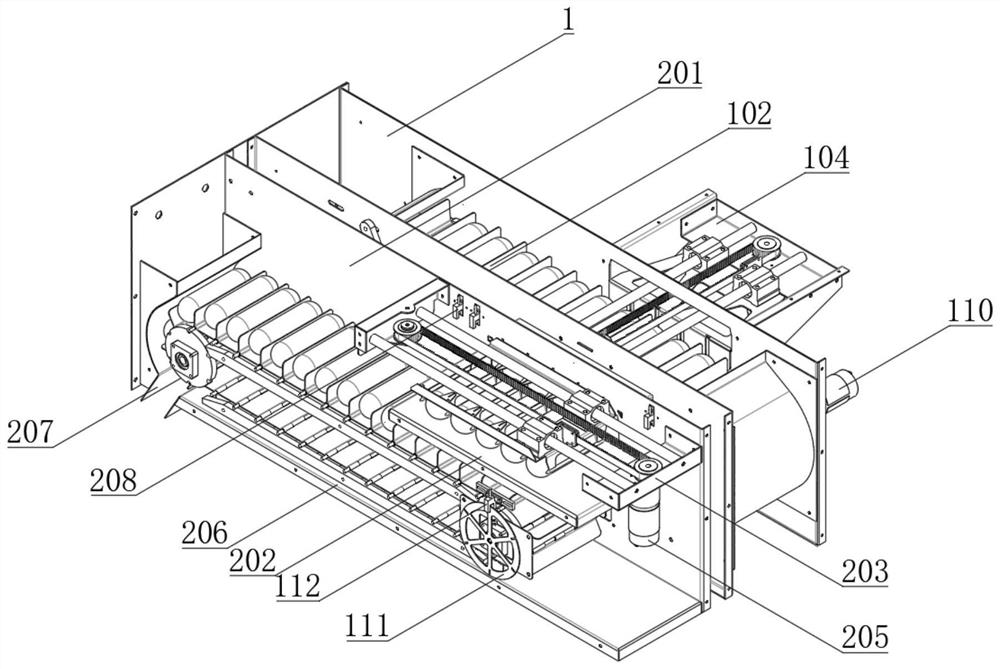

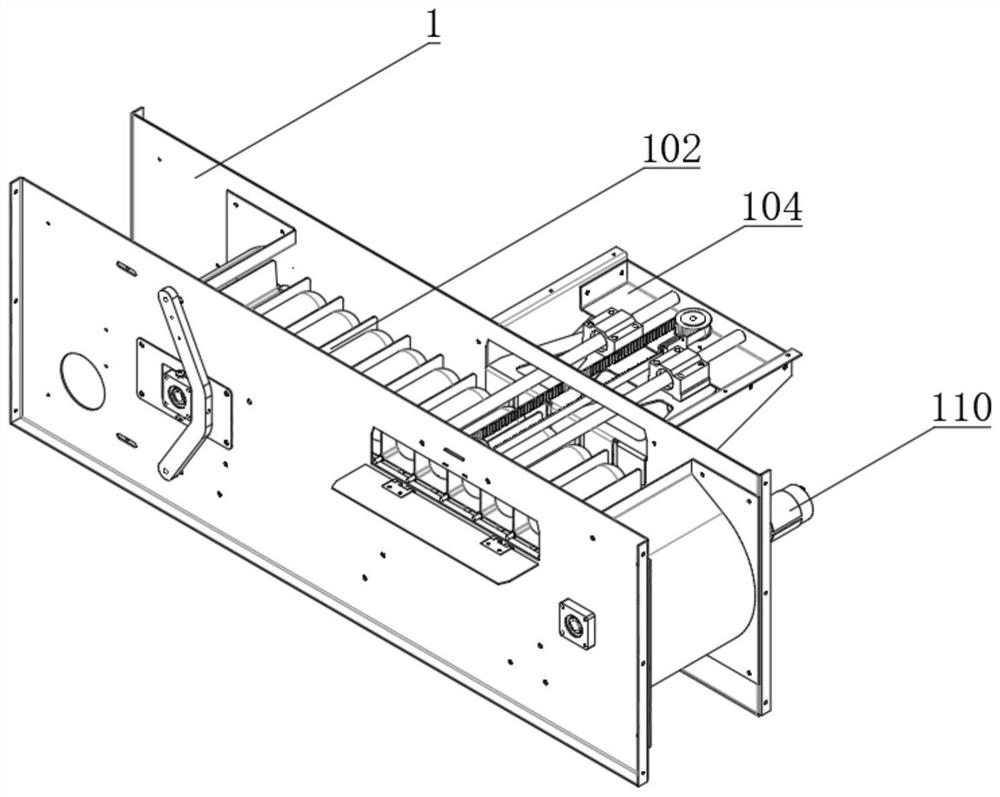

[0031] see Figure 1-7 , a full-automatic grilled sausage vending machine for unmanned vending, including a casing 1, an upper feeding bin 101 and a baking bin 201 are arranged inside the outer casing 1, and a transmission mechanism 102 is arranged inside the upper feeding bin 101 and the baking bin 201 One end of the loading bin 101 is equipped with a feeding mechanism, and the other end of the loading bin 101 communicates with the baking bin 201. The inner wall of the baking bin 201 is equipped with a baking plate 202, and the interior of the baking bin 201 is equipped with a sausage pushing mechanism. , a heat preservation zone is provided under the baking plate 202 .

[0032] In this embodiment, the sausage pushing mechanism pushes down the grilled sausage on the grilling plate 202, and can move the grilled sausage to prevent the grilled sausage from being burnt. The cooked sausages will fall on the conveying mechanism, and a heat preservation area is provided under the b...

Embodiment 2

[0035] According to Embodiment 1, the feeding mechanism includes a mounting frame 104 fixedly connected to the back side of the loading bin 101, the upper surface of the mounting frame 104 is fixedly connected with a crossbar 105, and the end of the crossbar 105 away from the mounting frame 104 is connected to the top of the loading bin 101. The inner wall is fixedly connected, and the outer surface of the cross bar 105 is sleeved with a push plate 106 .

[0036] In this embodiment, as an alternative, the crossbar 105 can be directly replaced by a hydraulic rod as a whole to provide a stronger thrust, and it is faster to push the sausage off the conveyor belt 102, and it can also improve the mounting frame 104. The quantity is adjusted. If the baking plate 202 is larger, multiple sets of push plates 106 can be set, so that a greater number of sausages can be pushed at one time.

Embodiment 3

[0038] According to Embodiment 2, the lower surface of the mounting frame 104 is fixedly connected with a No. 1 motor 107, and the output end of the No. 1 motor 107 is equipped with a synchronous belt 108. The inner wall of the feed bin 101 is fixedly connected, and the upper surface of the push plate 106 is fixedly connected with the outer surface of the synchronous belt 108 .

[0039] In this embodiment, as an alternative, the synchronous belt 108 can be replaced by a chain, and the driven wheel 109 can be replaced by a gear, and a runner can be added in the middle of the synchronous belt 108 for auxiliary rotation to prevent the synchronous belt 108 from falling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com