Cellulose-based structural floor panel assembly

A component and panel technology, applied in the direction of floor slabs, building components, structural elements, etc., can solve problems such as hindering rapid panel manufacturing, structural limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

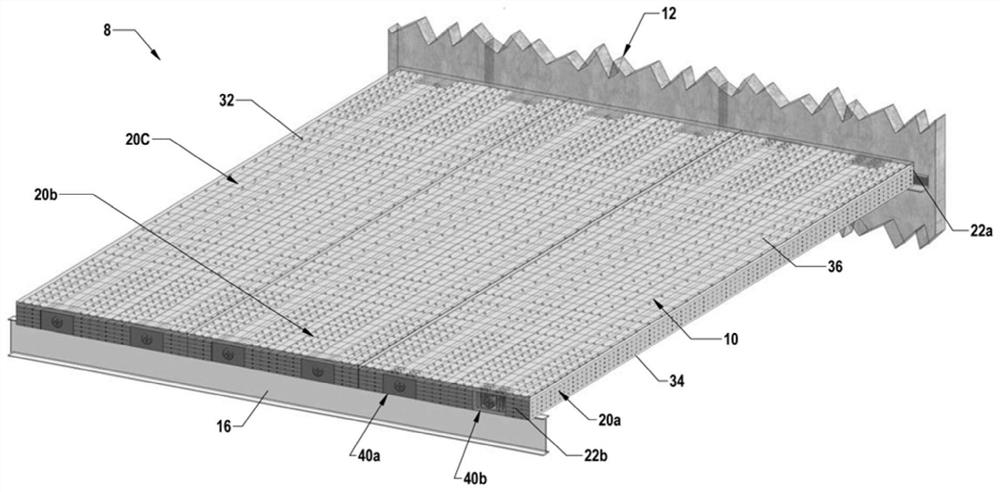

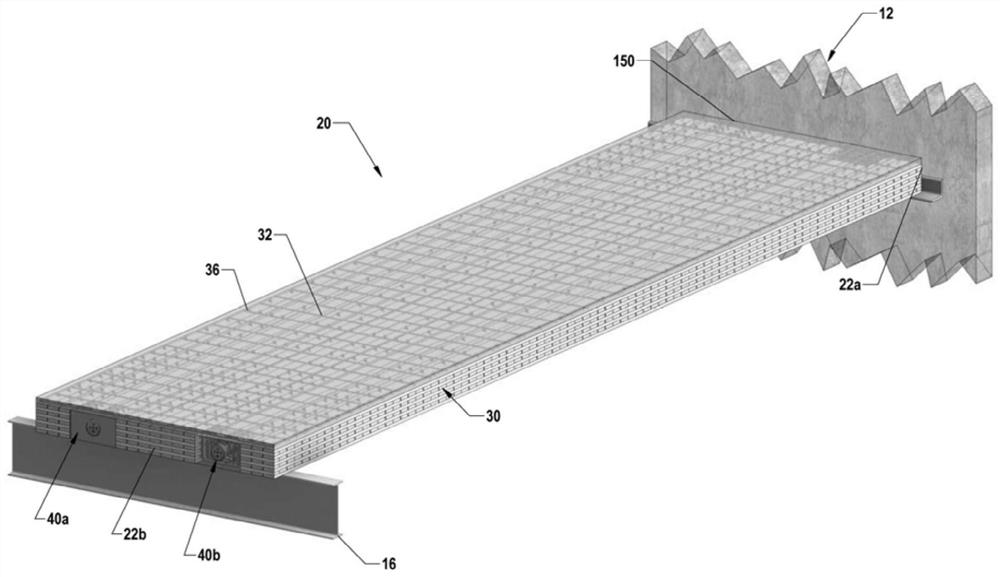

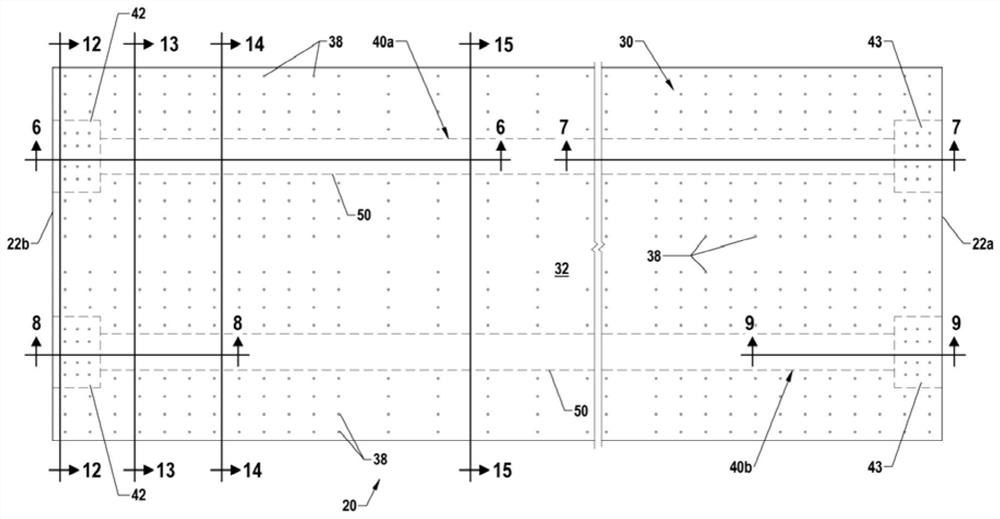

[0121] refer to figure 1 , shows a partial cross-sectional view of a Class A high rise building 8 having a building floor 10 formed using a plurality of structural floor panel assemblies 20a, 20b, 20c; and covered by a top concrete layer 36. As will be described, each of the floor panel assemblies 20a, 20b, and 20c are preferably prefabricated off-site as at least partially prefabricated units. The floor panel assembly 20 is delivered substantially ready for installation in a substantially unsupported position completely spanning between the building elevator core 12 and the outermost building perimeter supports, such as the peripherally extending I-beam supports 16, or other such steel or concrete structures.

[0122] figure 1 Each floor panel assembly 20a, 20b, 20c is shown because each is generally rectangular and extends longitudinally from a respective innermost first end 22a fixedly coupled to the building core 12 to a solid to the outermost second end 22b of the peri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com