Continuous automatic binding machine and use method thereof

A binding machine and automatic technology, applied in botany equipment and methods, applications, horticulture, etc., can solve the problems of increasing enterprise costs, slow operation efficiency, and air compaction of bacterial bags, and achieve fast knotting operations and intelligent knotting knot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

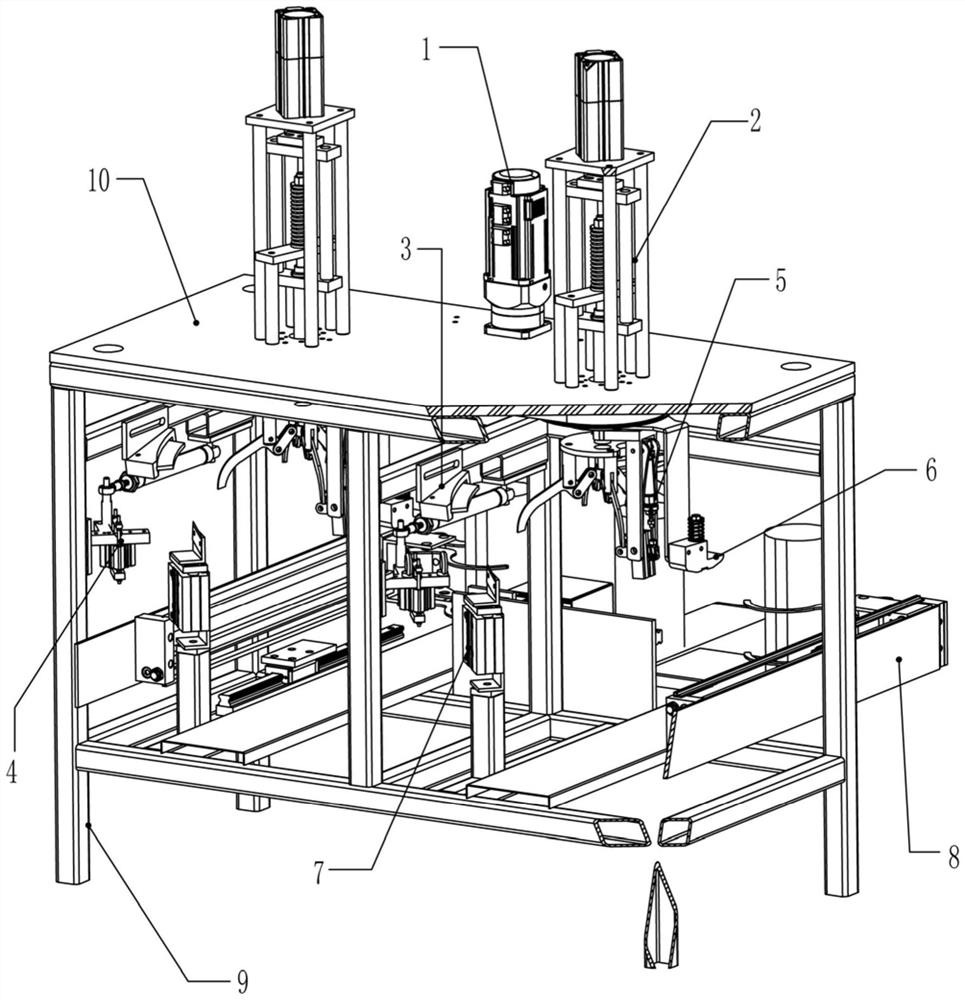

[0035] A continuous automatic binding machine, such as Figure 1-11As shown, it includes a servo power mechanism 1, a bag lifting mechanism 2, a rope-off mechanism 3, a rope-feeding and pulling mechanism 4, a rope-knotting mechanism 5, a rope-clamping mechanism 6, a rope-cutting mechanism 7, a feeding mechanism 8, a machine Frame 9 and main board 10; Main board 10 is installed on the top of frame 9; Servo power mechanism 1, folder bag elevating mechanism 2 are all installed on main board 10; The rope winding mechanism 6 is connected to the output end of the servo power mechanism 1 by transmission, the rope knotting mechanism 5 is connected to the output end of the bag lifting mechanism 2 by transmission, the rope sending mechanism 4 is installed on the side of the frame 9, the rope cutting mechanism 7, the feeding The mechanism 8 is installed on the frame 9, the output end of the feeding mechanism 8 is located directly below the output end of the bag lifting mechanism 2, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com