All-ceramic removable denture structure and manufacturing method thereof

A production method and denture technology, applied in the field of removable dentures and medical devices, can solve problems such as affecting the daily life of patients, affecting the sense of use experience, and long maintenance cycle time, so as to reduce production costs and cycles, improve user experience, and avoid problems. The effect of uneven stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

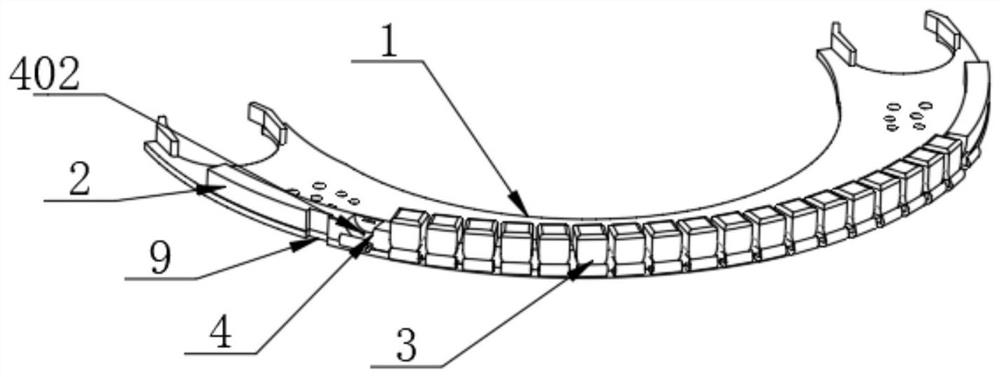

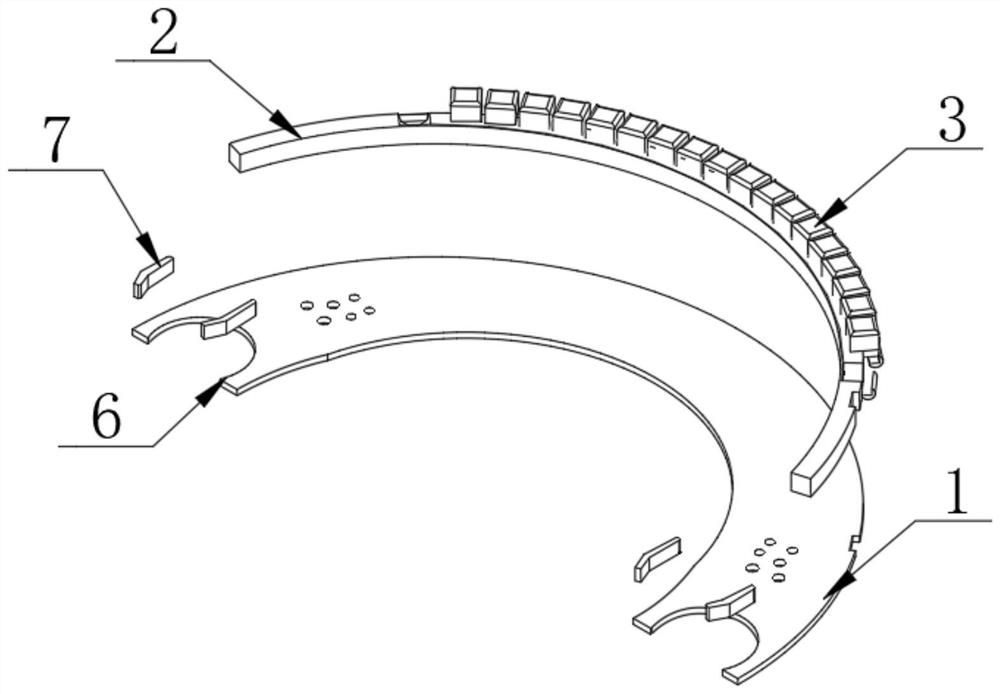

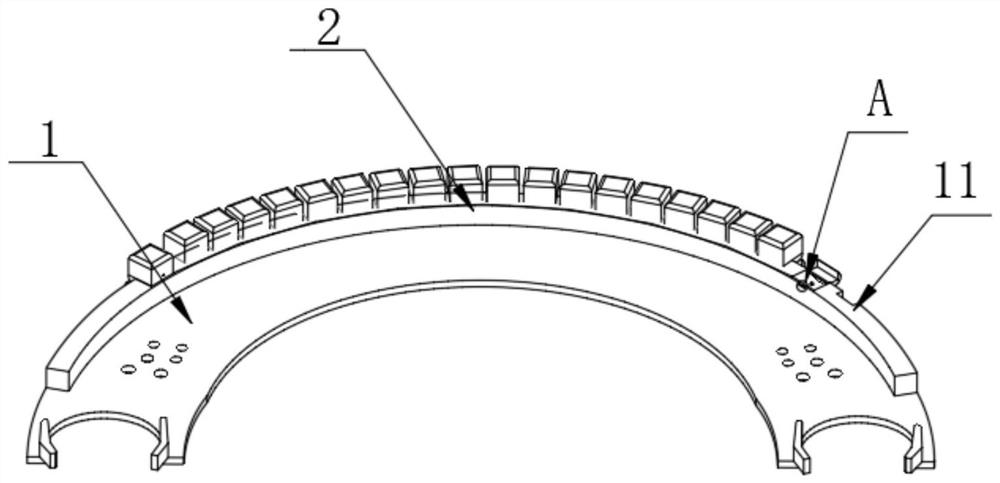

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8, this embodiment discloses a removable denture structure made of all-ceramic, including a base plate 1 that fits the oral cavity structure, a connecting plate 2 is fixedly connected to the top of the base plate 1, and a plurality of positioning grooves 4 are opened on the top of the connecting plate 2, and a plurality of Artificial teeth 3 are provided inside the positioning grooves 4, and a plurality of adjustment grooves 403 corresponding to the positioning grooves 4 are provided on the outside of the connecting plate 2. Fixing parts are provided between the connecting plate 2 and the artificial teeth 3, and the artificial teeth 3 and the artificial teeth 3 are connected to each other. The connecting plate 2 is connected by a fixing piece, the fixing piece includes a first connecting block 401, the first connecting block 401 is arranged inside the adjusting groove 403, a screw 405 is provide...

Embodiment 2

[0040] see again figure 1 , figure 2 , Figure 5 and Figure 6 , both sides of the top of the substrate 1 are provided with a number of lamination holes 10, both ends of the substrate 1 are provided with fixing grooves 6, both sides of the two fixing grooves 6 are provided with fixing strips 7, and the fixing strips 7 are fixedly connected to the top of the substrate 1, By setting the fixing groove 6 inside the oral cavity and matching the jaws with each other, the base plate 1 is more stable when it is fixed, and the fixing strip 7 is clamped to the joint by external force. Fitting the first fitting part 9, a second fitting part 11 with the same size as the first fitting part 9 is opened on the outside of the connecting plate 2, and the first fitting part 9 is fitted with the remaining tooth roots in the patient's oral cavity , to avoid discomfort for the patient.

[0041] Specifically, by opening a number of bonding holes 10 on the top of the substrate 1, the bonding be...

Embodiment 3

[0043] see again figure 1 , figure 2 , Figure 5 and Figure 6 , the present embodiment discloses that the artificial tooth 3 material in the removable denture structure made of all-ceramic adopts an all-ceramic crown. Teeth can be divided into 1. Glass-ceramic all-ceramic teeth. Such as: Empress I, II, and III generations of hot-pressed porcelain crowns, glass-infiltrated porcelain crowns, and glass-ceramic crowns ground by CAD / CAM technology, etc. 2. Alumina and zirconia all-ceramic teeth, through the application of CAD / CAM technology to grind the alumina and zirconia inner crowns, and then add the outer layer of porcelain through layered porcelain technology, the finished all-ceramic teeth or no outer layer The full zirconium crown decorated with porcelain can be properly selected according to the needs of the patient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com