Method for pre-stressed reinforcing concrete compression member

A compression member, prestressing technology, applied in building construction, building maintenance, construction, etc., can solve the problems of thickness error of force transmission plate, complicated construction process, large cumulative error, etc., to reduce the stress level of the original structure, eliminate the Strain hysteresis, the effect of improving the total bearing capacity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

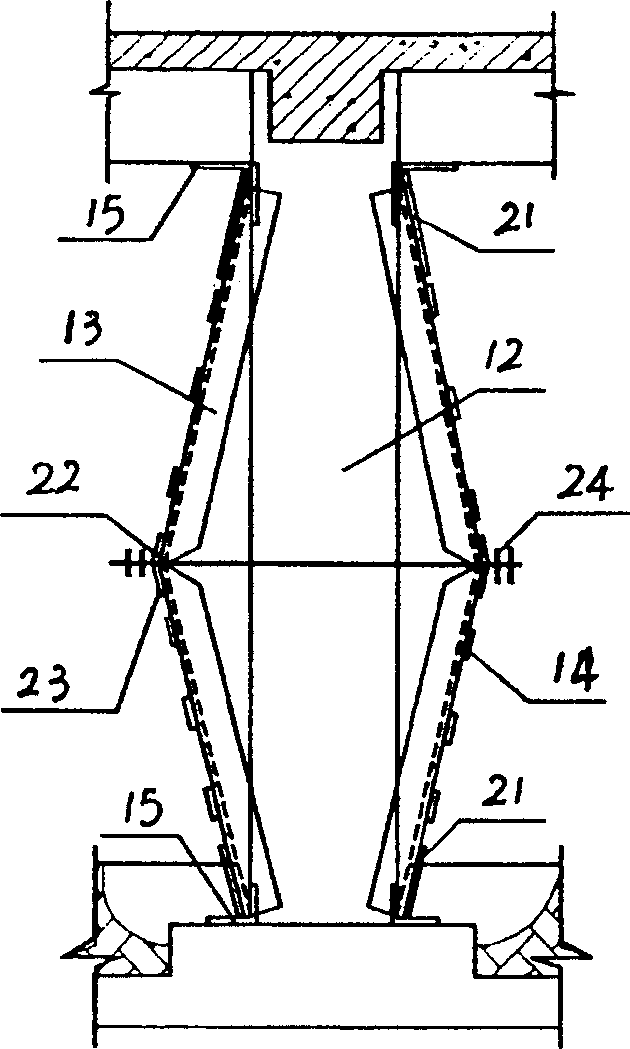

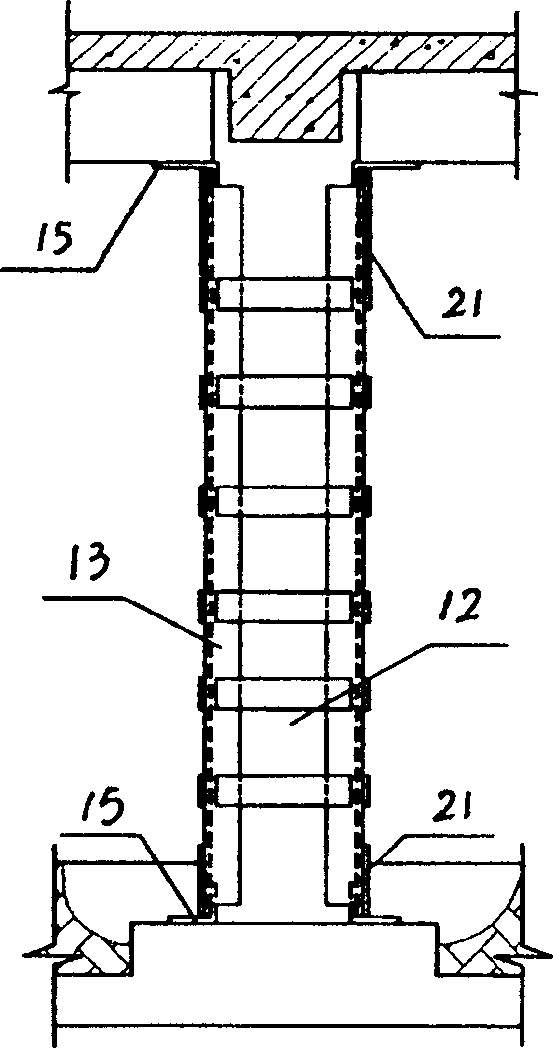

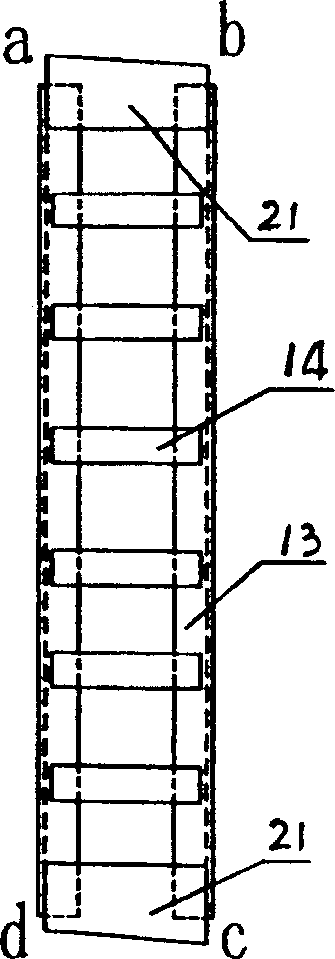

[0096] Such as Image 6 , Figure 7 As shown, the method of prestressing reinforced concrete compression members is divided into five steps: 1) prestress calculation, 2) jack torsion calculation, 3) outsourcing strut angle steel and jack installation, 4) prestress application, 5) Fixing and jack removal. 1), prestress calculation

[0097] a. Axial Force Calculation

[0098] (1) Determine the full axial compressive bearing capacity N to be borne after reinforcement;

[0099] (2) According to the current "Code for Design of Concrete Structures" (GBJ10-89), calculate the axial compressive bearing capacity of the original reinforced concrete N0 :

[0100] N 0 =(A co f co +A' so f' yo ) (4.1)

[0101] where N 0 ——the axial compressive bearing capacity of the original column;

[0102] ——coefficient of stability of original column;

[0103] A co - the cross-sectional area of the original column;

[0104] f co — design value of concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com