3D printing energy storage container shell

A 3D printing and container technology, applied in the field of containers, can solve problems such as insufficient strength, and achieve the effects of preventing shaking, ensuring safe transportation, and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

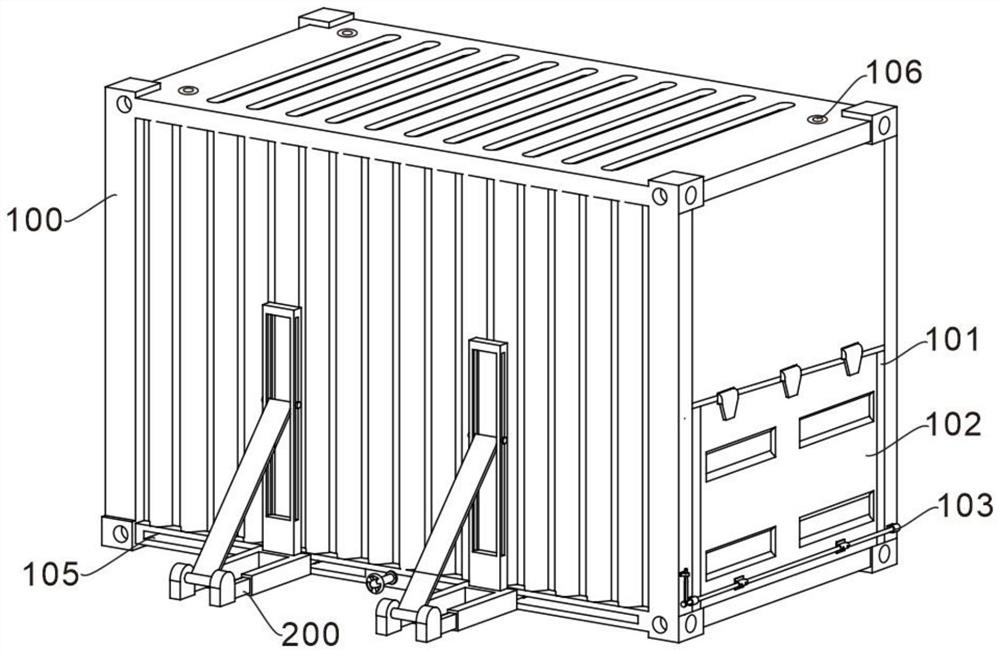

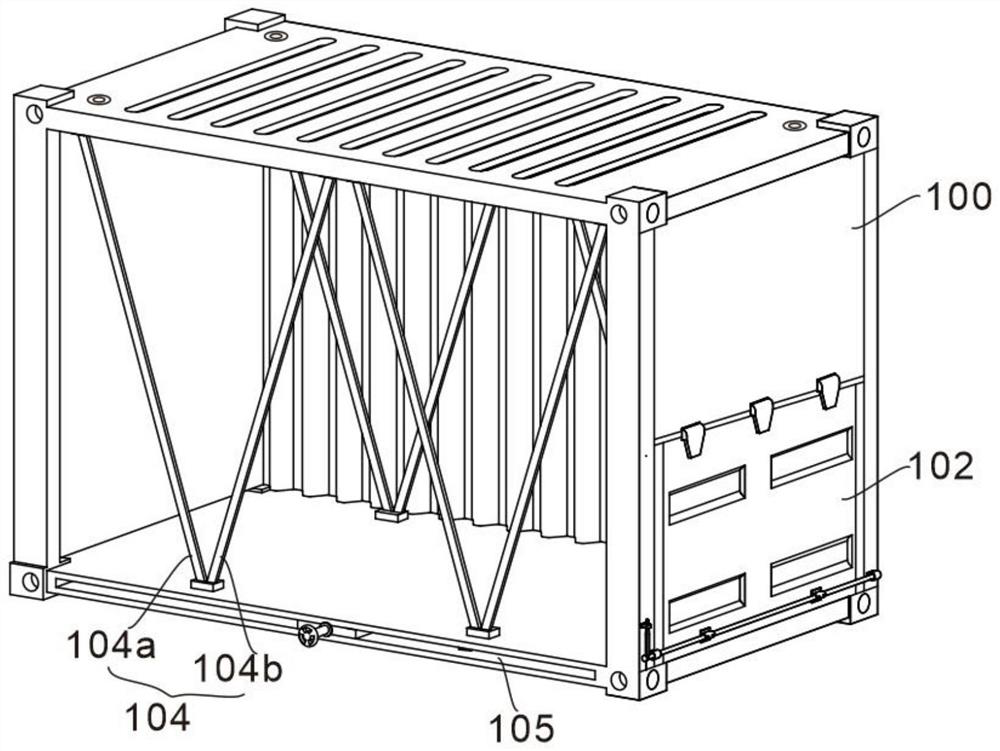

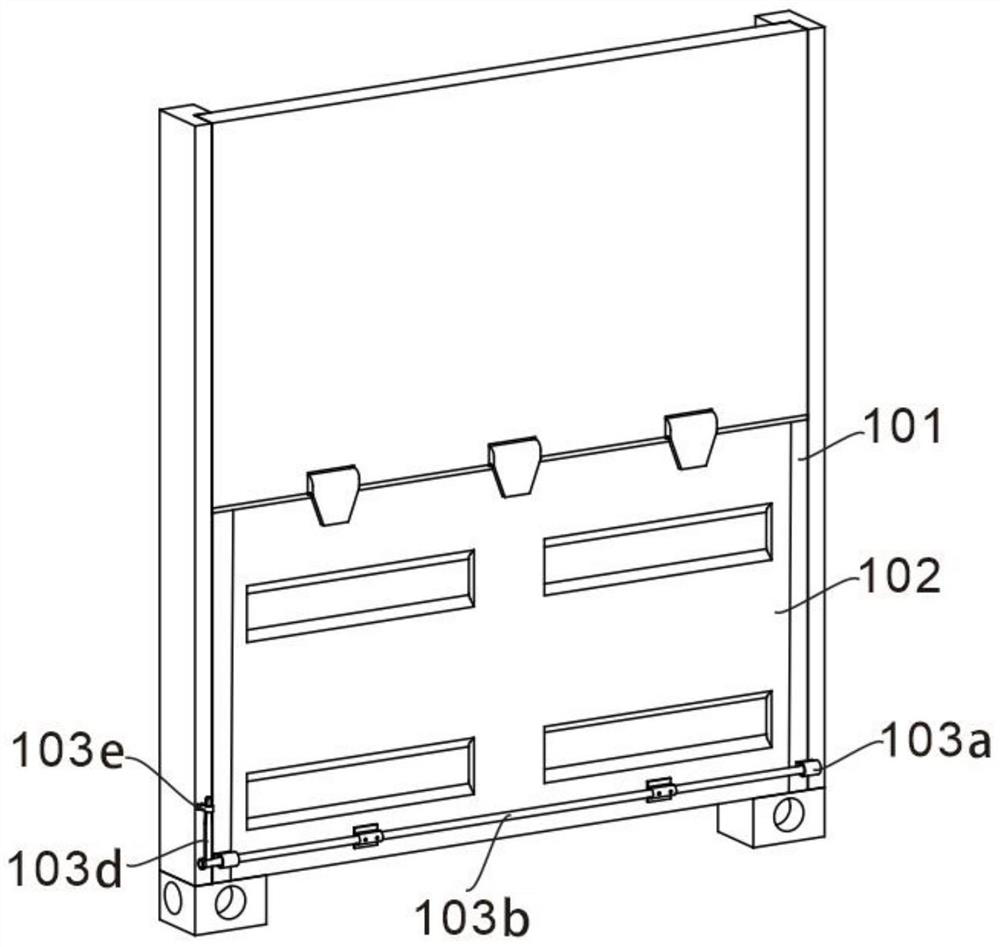

[0029] refer to Figure 1 to Figure 4 , which is the first embodiment of the present invention, this embodiment provides a 3D printed energy storage container shell, which includes a box body 100, the box body 100 is manufactured by 3D printing technology, and the bottom of one side of the box body 100 is provided with Door frame 101, the top of door frame 101 is rotatably connected with box door 102, and lock piece 103 is arranged between box door 102 and box body 100, box door 102 is used for opening or closing the outlet of box body 100, and lock piece 103 is used for fixing Box door 102, box body 100 interior is provided with reinforcing piece 104, and reinforcing piece 104 is used for enhancing the overall solidity of box body 100, and box body 100 bottom two sides are provided with accommodating cavity 105; Support assembly 200, comprises moving piece 201 and The supporting part 202, the supporting part 202 is connected with the moving part 201, the moving part 201 is ar...

Embodiment 2

[0035] refer to Figure 1 to Figure 8, is the second embodiment of the present invention, and it is different from the first embodiment in that: the moving part 201 includes a rotating hand wheel 201a, a first bevel gear 201b, a second bevel gear 201c and a rotating screw rod 201d, and the rotating hand wheel 201a Connected with the first bevel gear 201b, the rotating hand wheel 201a extends from the cavity 101 to the outside of the box body 100, the second bevel gear 201c meshes with the first bevel gear 201b, and the second bevel gear 201c is connected with the rotating screw rod 201d, The end of the rotating screw 201d away from the second bevel gear 201c is connected to the inner wall of the cavity 101 .

[0036] A displacement bolt 201e is sleeved on the outer side of the rotating screw 201d, and the displacement bolt 201e is connected with a telescopic rod 201f, and the telescopic rod 201f is connected with a sliding block 201g, and the sliding block 201g passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com