Straightening equipment for reinforcing steel bars

A technology for steel bars and equipment, applied in the field of steel bar straightening equipment, can solve problems such as inability to complete steel bar straightening, and achieve the effect of improving the straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

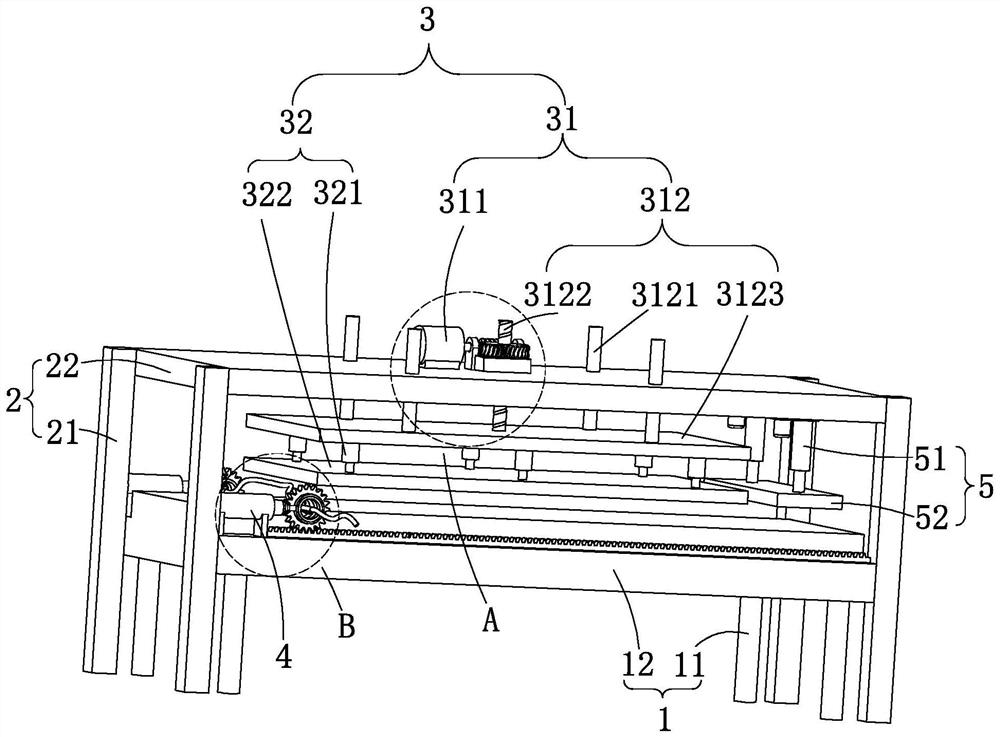

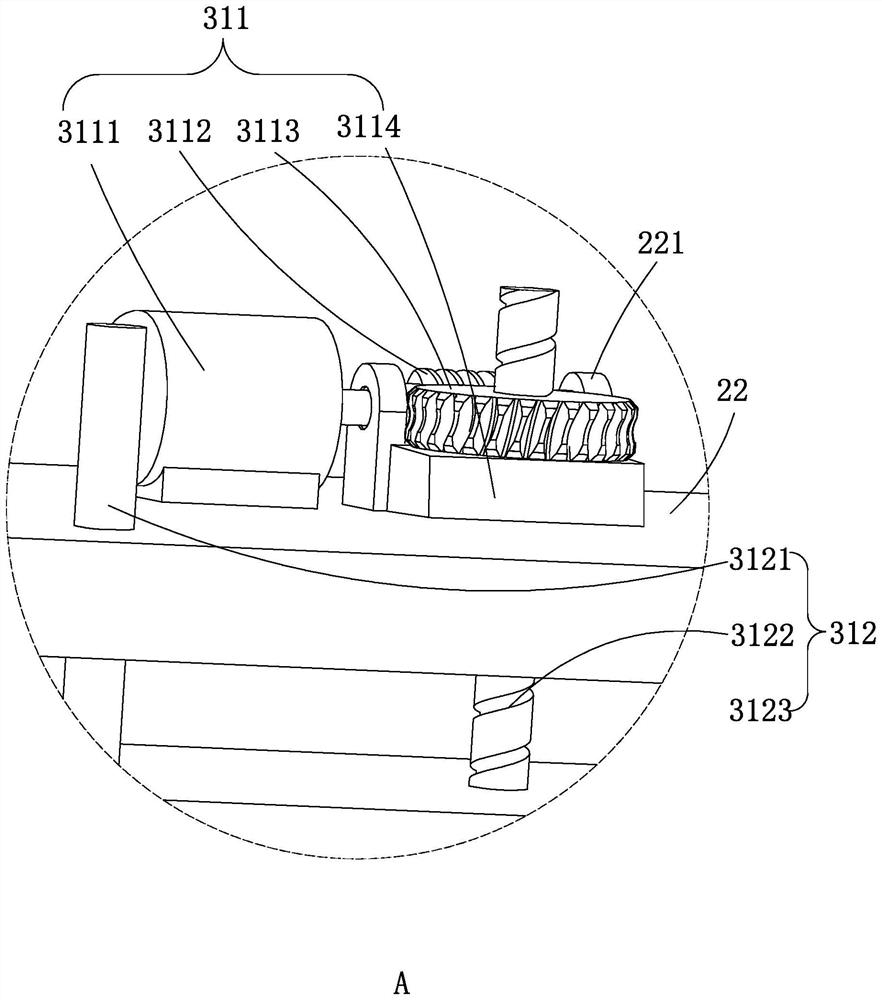

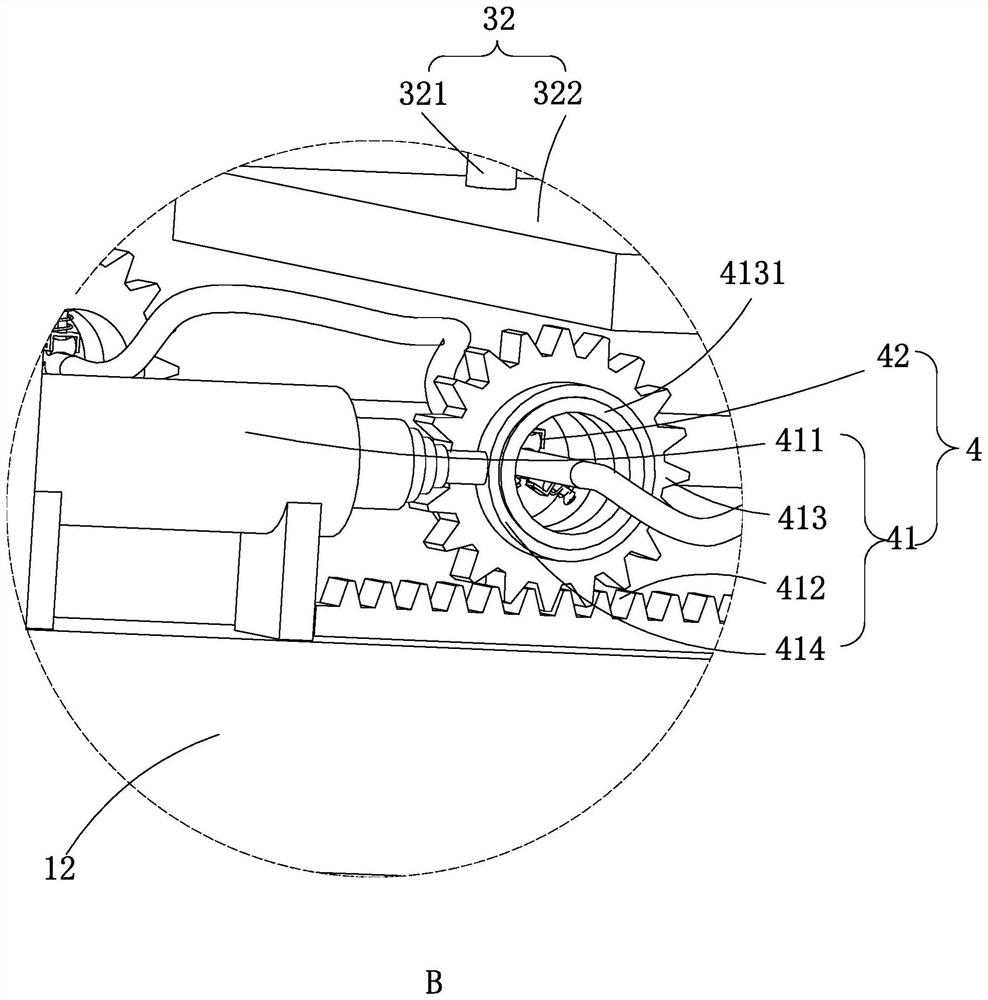

[0033] The following is attached Figure 1-4 The application is described in further detail.

[0034] The embodiment of the present application discloses a straightening device for steel bars. refer to figure 1 , a kind of straightening equipment for steel bars, including a processing table 1 stable on the ground, a mounting frame 2 stable on the ground, a strong pressure mechanism 3 connected to the mounting frame 2 for straightening steel bars, and connected to the processing table 1 opposite The moving mechanism 4 on both sides is used to make the steel bar roll, and the correction mechanism 5 connected to the mounting frame 2 to fine-tune the surface of the steel bar. The pressing mechanism 3 and the correction mechanism 5 are both located directly above the processing table 1. The bottom surface of the pressing mechanism 3 reaches the processing The minimum distance from the upper surface of table 1 and the minimum distance from the bottom surface of correction mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com