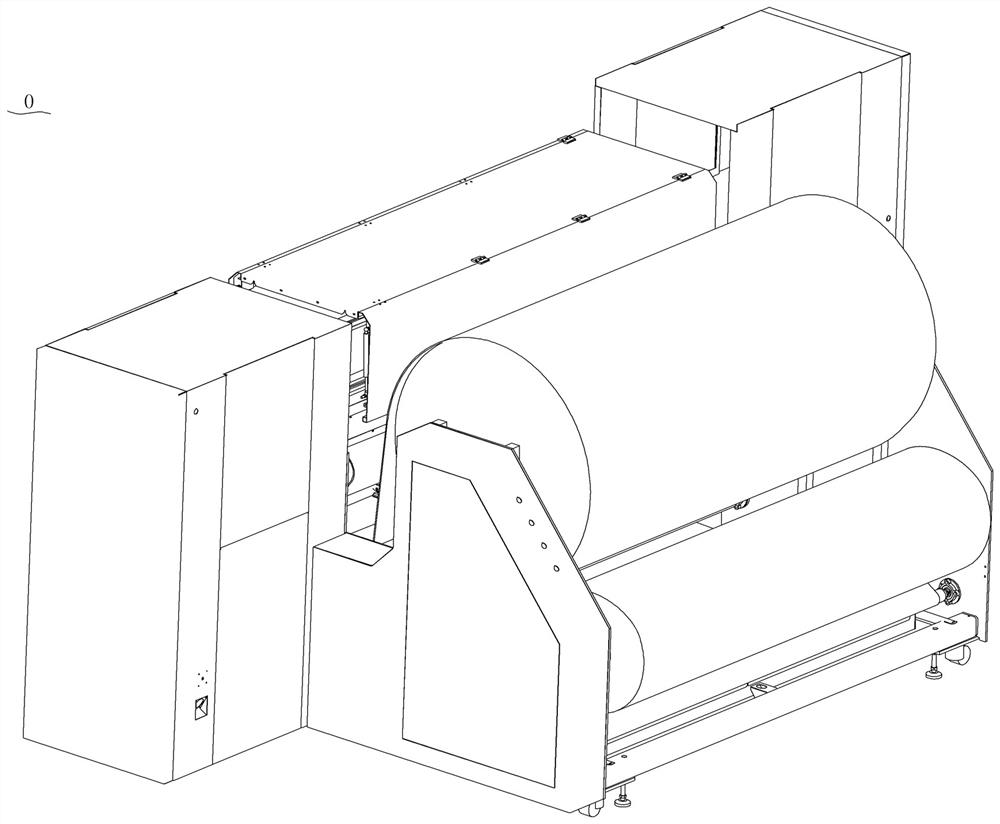

Industrial digital printing machine

A digital printing machine, printing machine technology, applied in the direction of printing, printing devices, transfer materials, etc., can solve the problems of inability to adjust the position, unable to ensure uniform flow of printed matter, and affect the printing effect, so as to achieve the effect of ensuring the printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

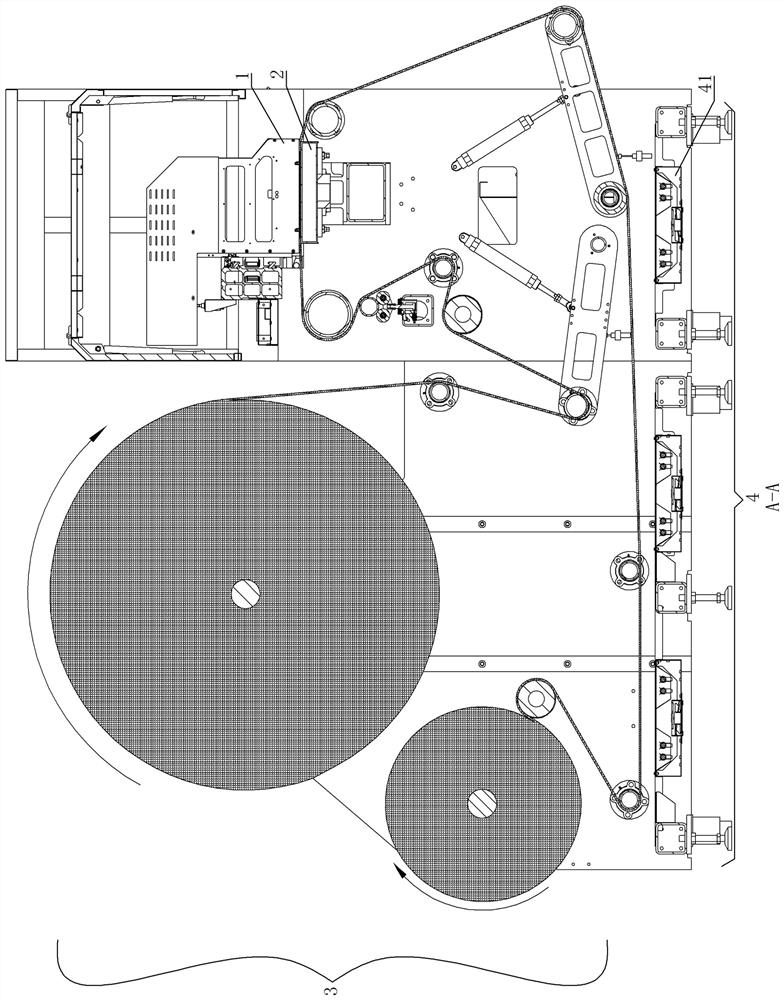

[0049] Example: see Figure 1-28 , an industrial digital printing machine, including a nozzle trolley arranged inside the printing machine, a printing platform, a printed matter guiding system and a drying system arranged perpendicular to the printing machine; the drying system is arranged on the printed matter guiding system Next; the nozzle trolley is on the printing platform to print on the printed matter; the printed matter guiding system guides the printed matter so that the printed flow passes through the printing platform;

[0050] The nozzle trolley is set above the printing platform, and the rear wall is connected to the lifting plate; the lifting plate has a left and right moving component, which drives the nozzle trolley to move left and right; the back wall of the trolley is provided with a plumb long hole; there are plumb screws passing through the plumb long hole and the lifting The plate is connected; through the cooperation of the plumb long hole and the plumb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com