Robot for grabbing cylindrical workpiece

A robot and cylindrical technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easy slipping, axial instability of cylindrical workpieces, and inability to support and clamp cylindrical workpieces, etc., to achieve The effects of avoiding slippage, improving transportation stability, and improving grasping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

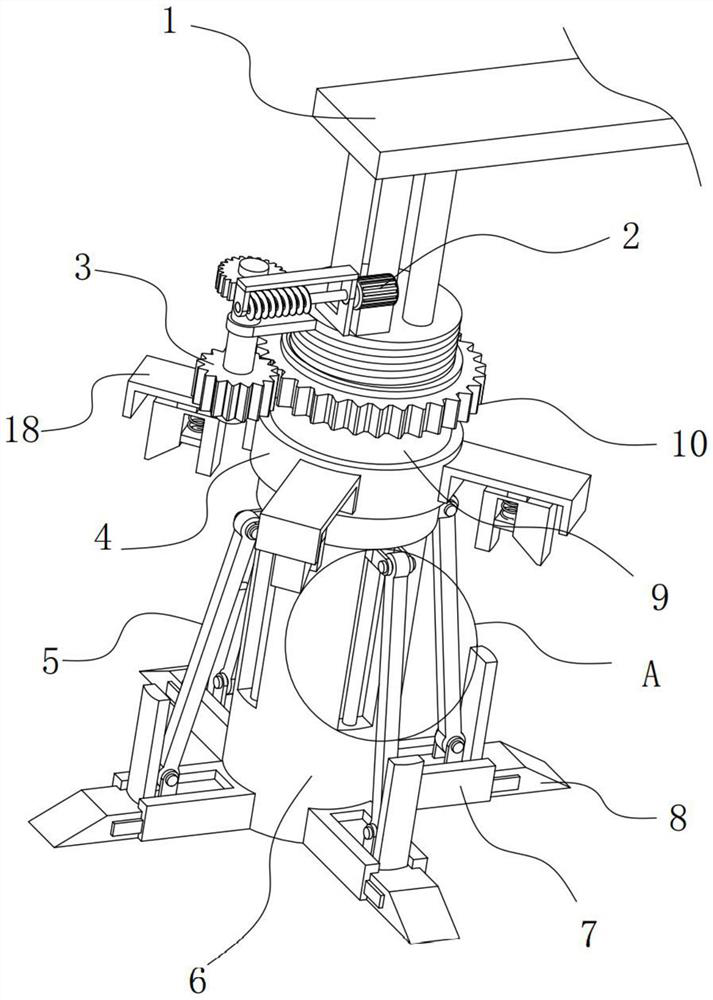

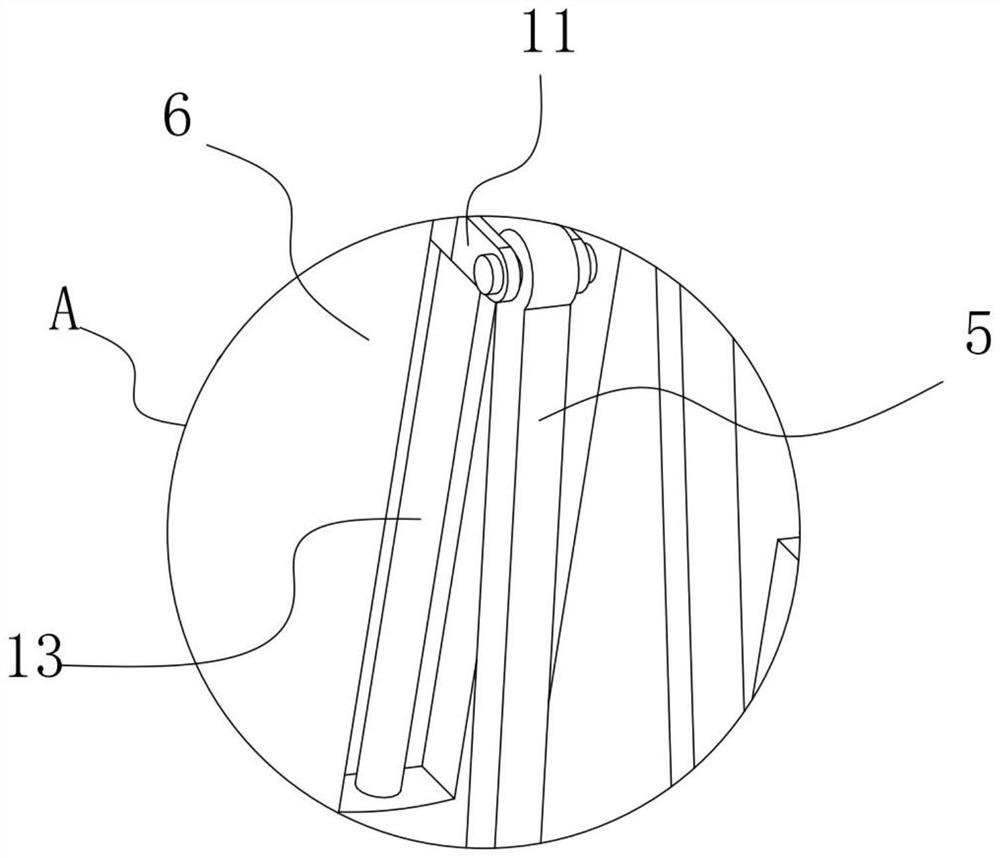

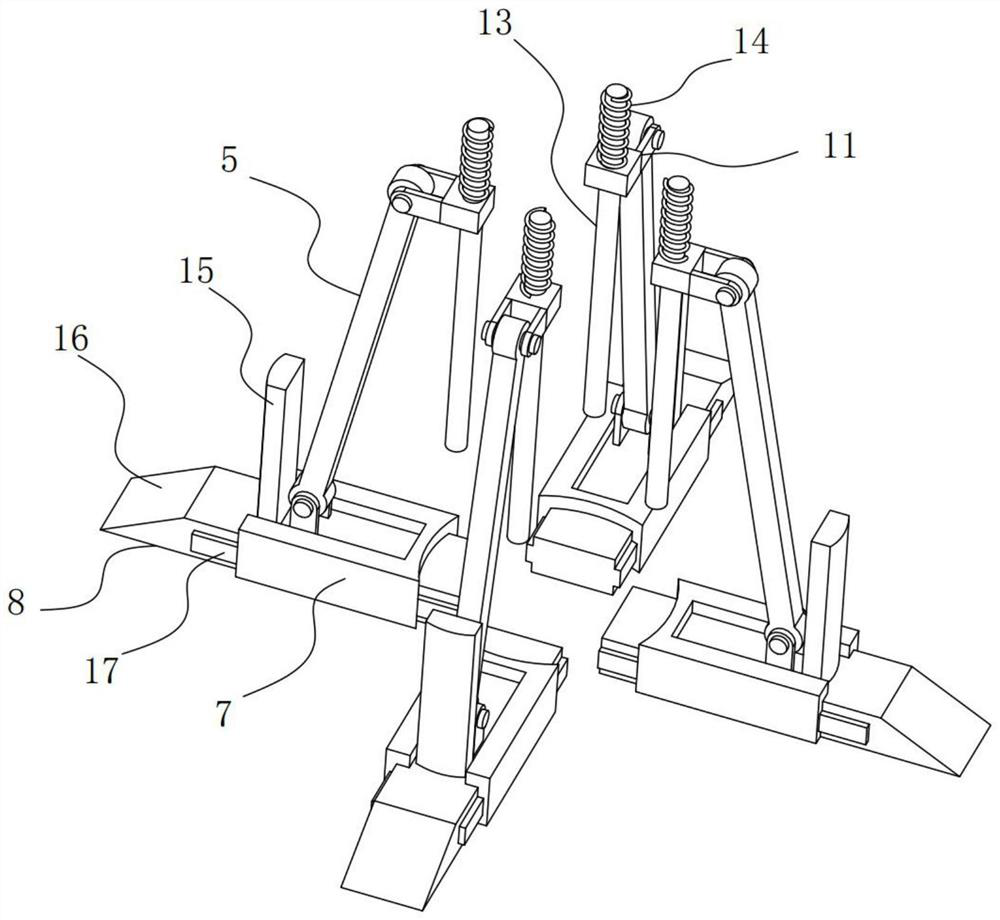

[0022] see Figure 1-5 , a robot for grabbing a cylindrical workpiece, including a connecting frame 1, a column 6 is fixed on the connecting frame 1, a plurality of guide sleeves 7 are installed on the side wall of the column 6, and each guide sleeve 7 is slidably installed with The extension plate 8 is provided with a wedge surface I16, the threaded sleeve 9 is threaded on the column 6, and a thrust mechanism is connected between the threaded sleeve 9 and the guide sleeve plate 7, and the threaded sleeve 9 is connected by a bearing. A collar 4 is installed, and an extension frame 18 is fixed on the side wall of the collar 4, and an axial clamping mechanism is installed on the extension frame 18.

[0023] The connecting frame 1 in this robot is connected with the external control equipment, and the position of the connecting frame 1 is adjusted through the existing external control equipment, so that the column 6 can be extended into the interior of the cylindrical workpiece, ...

Embodiment 2

[0030] see Figure 1-5 , on the basis of Embodiment 1, in addition, the clamping mechanism includes a limit rod 22 and a horizontal slider 20 slidingly sleeved on the limit rod 22, and a clamp 23 is fixed on the lateral slider 20, and the lateral slider 20 A connecting spring 19 is connected with the extension frame 18 , and a card seat 23 is fixed on the transverse slider 20 , and a pressing assembly is installed on the card seat 23 .

[0031] The pressing assembly includes a sliding groove 26 provided on the card seat 23, on which a pressing plate 25 is slidably installed, and a pushing spring 21 is connected between the pressing plate 25 and the card seat 23, and a wedge surface II24 is provided on the card seat 23.

[0032] Through the above arrangement, in the process of the vertical movement of the threaded sleeve 9, the threaded sleeve 9 can drive the collar 4 to move, and the extension frame 18 on the collar 4 moves to realize the downward movement of the deck 23, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com