Telescopic railway ballast bed fine material blowing, sucking and collecting device

A track bed and small technology is applied in the field of retractable railway track bed blowing and absorbing devices for fine materials, which can solve the problems of insufficient obstacle avoidance, low work efficiency, poor adaptability, etc., and achieve the effect of improving cleaning efficiency and cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

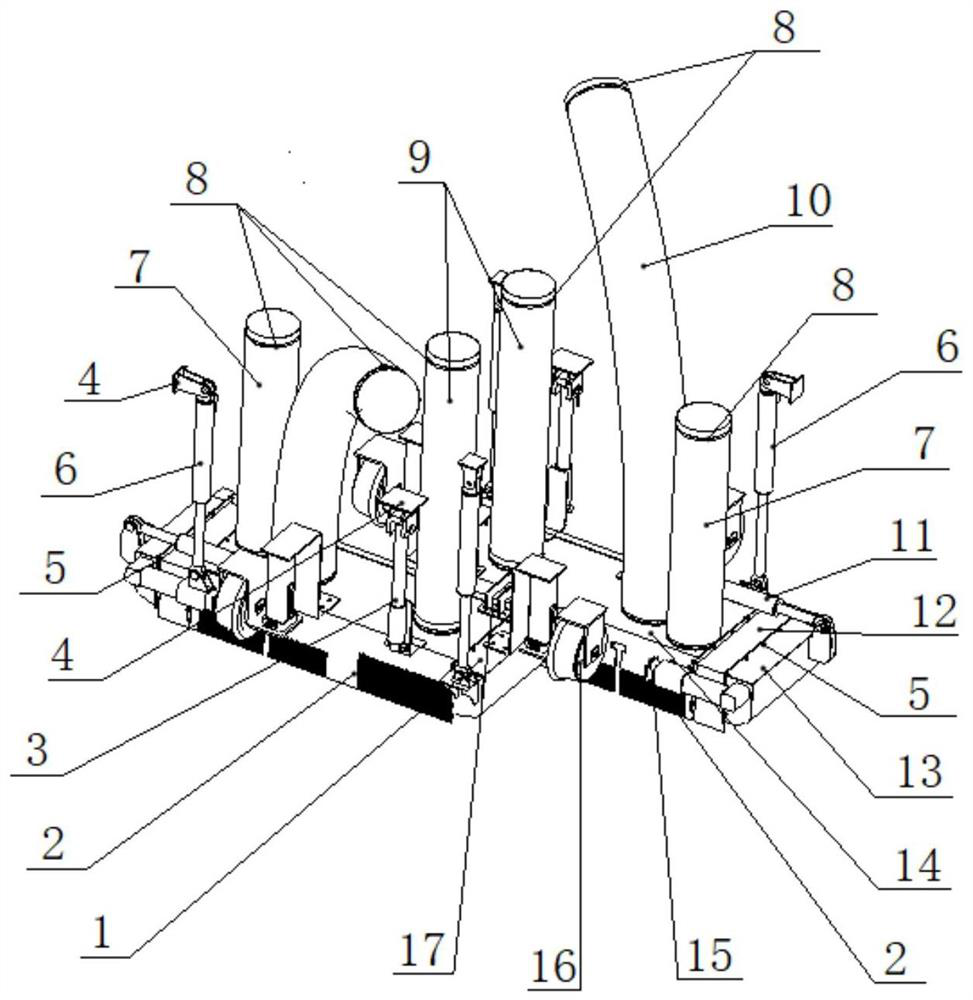

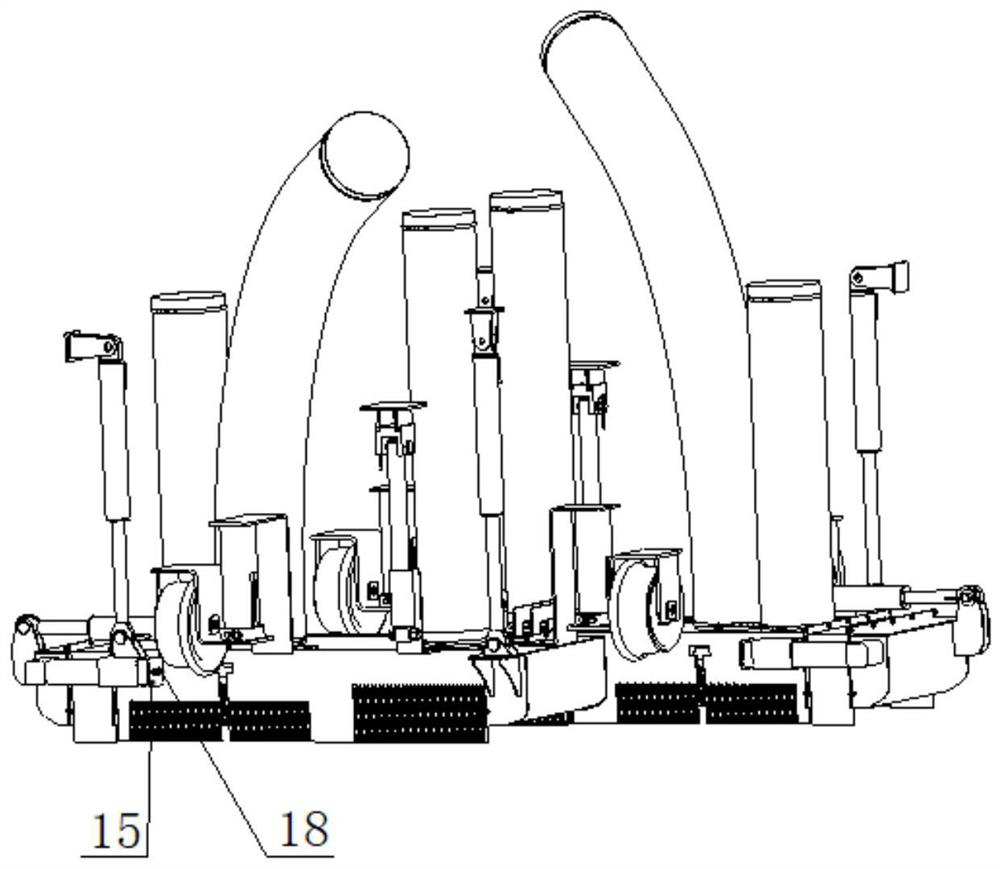

[0044] This embodiment discloses a retractable railway track bed fine material blowing and collecting device, such as figure 1 , figure 2 , image 3 As shown, the main body includes blowing and suction shells 14 distributed symmetrically in a staggered manner and their installation attachments, and the blowing and suction shells 14 are fixed together by connecting supports 17 .

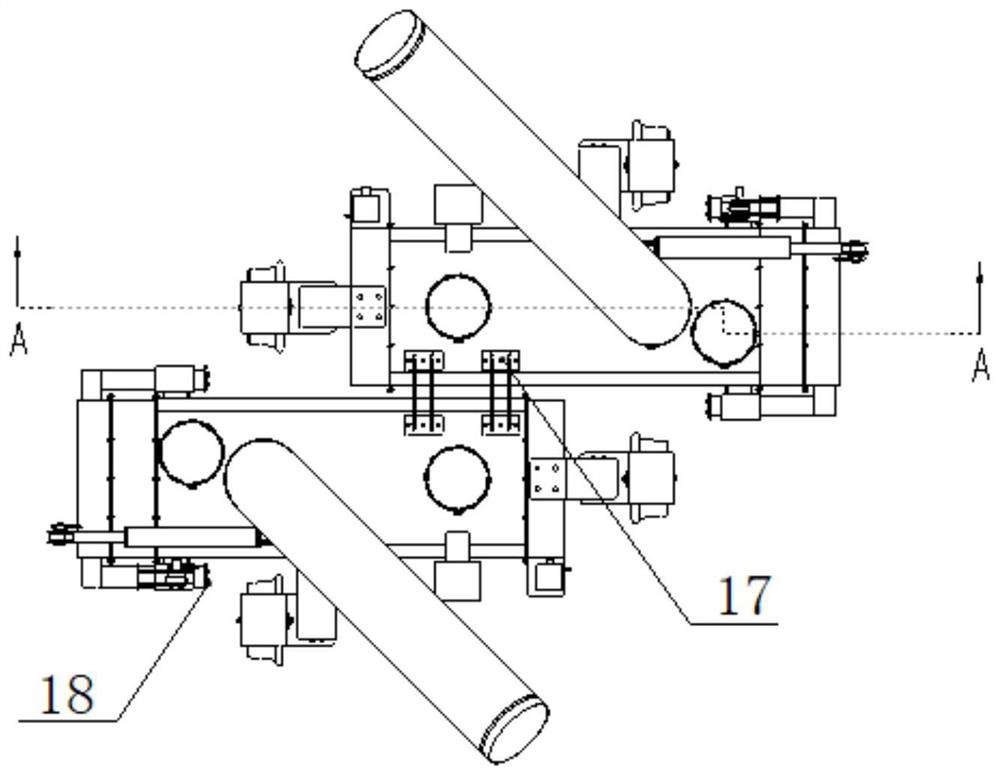

[0045] to combine Figure 5 , Figure 6 , Figure 7 ,in Figure 6 For the upward viewing angle, Figure 7 Shown is a schematic diagram of the blower cover with the top plate 1402 removed. Figure 7As shown, the right air duct deflector 1408, the left air duct deflector 1414, and two side air duct deflectors 141...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com