Experimental method for stone impact prevention performance of rubble road and whole vehicle

A technology for gravel roads and gravel, which is applied in the field of gravel roads and in the field of vehicle anti-stone impact performance experiments, can solve the problem of high stone impact strength in the chassis area, reduce maintenance costs, avoid road water accumulation, and ensure accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

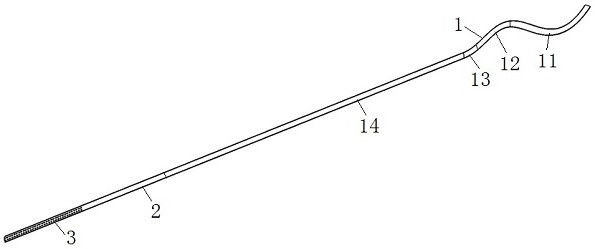

[0028] see figure 1 , the gravel road shown includes a gravel road section 1, a deceleration road section 2 and a clearing road section 3 connected in sequence, and the gravel road section 1 includes a first curve 11, a second curve 12, and a transition curve connected in sequence 13 and the straight road 14, the turning of the first curve 11 and the second curve 12 is opposite.

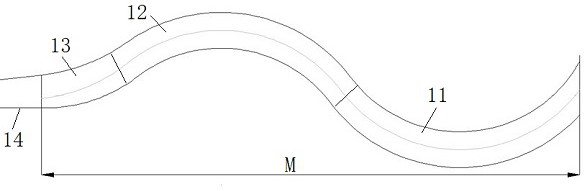

[0029] In order to ensure that the vehicle can pass through the first curve 11 and the second curve 12 smoothly, specifically, the first curve 11 is a right-hand curve with a turning radius of 25m; the second curve 12 is a left-hand curve, The turning radius is 25m; the turning radius of the transition curve 13 is 28m. see figure 2 , The sum of the lengths of the first curve 11, the second curve 12, and the transition curve 13 is 100m, and the width of the first curve 11, the second cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com