Illuminating device and imaging method for visual inspection of defects on outer surface of steel pipe

A lighting device and visual inspection technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as uneven lighting of steel pipes, and achieve the goal of preventing serious reflections, leak detection, and 360° uniform lighting imaging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

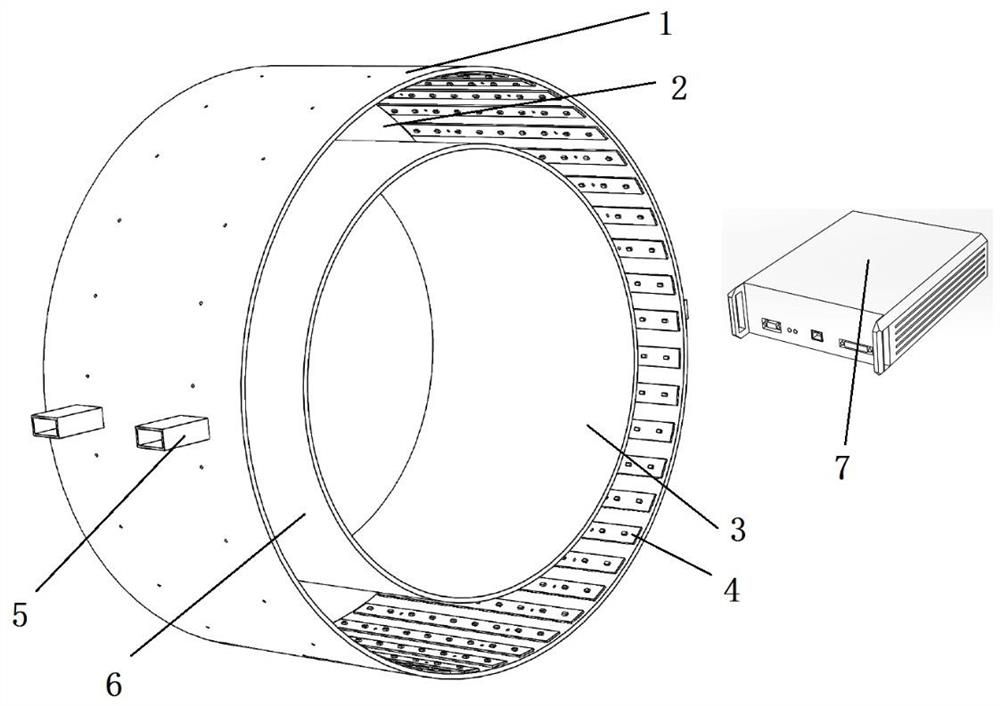

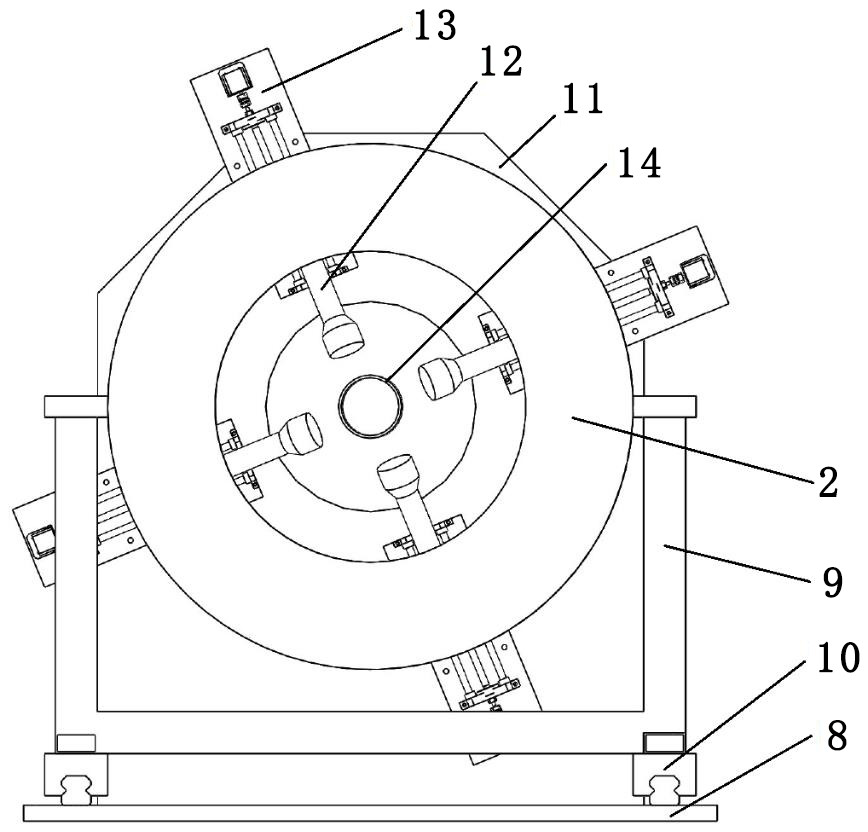

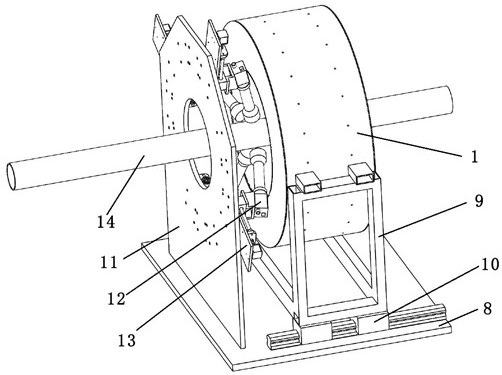

[0028] Such as Figure 1-3 As shown, a lighting device for visual detection of defects on the outer surface of steel pipes includes a lamp housing 1 and a lamp shade 3 arranged concentrically, the lamp housing 3 is located in the lamp housing 1, and a connecting The side plate 2, the side plate 2 is located on the opposite sides of the lamp housing 1 and the lampshade 3; the inner wall of the lamp housing 1 is provided with a plurality of circumferentially arranged LED light strips 4, and the LED light strips 4 are arranged facing the lampshade 3; the lampshade 3 It is made of transparent material, and the outer surface of the lampshade 3 is attached with a uniform light film 6; the lamp housing 1 is provided with a drive controller 7 electrically connected to the LED light bar 4, and the drive controller 7 synchronously controls all the LED light bars...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com