Lens module, manufacturing method of lens module and electronic equipment

A lens module and manufacturing method technology, applied in installation, optics, instruments, etc., can solve the problems of reducing the imaging quality of the lens module, pollution, obstructing the passage of light through the convex structure, etc., so as to reduce the risk of being scratched or contaminated with stains. Risk, increase the screen ratio, reduce the effect of the risk of demoulding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] Words such as "first" and "second" in the description of the present application are used for description purposes only, and should not be understood as indicating or implying relative importance or implicitly indicating the quantity of indicated technical features.

[0093] In this application, unless otherwise clearly stipulated and limited, the term "connection" should be understood in a broad sense, for example, "connection" can be a fixed connection, a detachable connection, or an integral body; it can be a direct connection, or Can be connected indirectly through intermediaries.

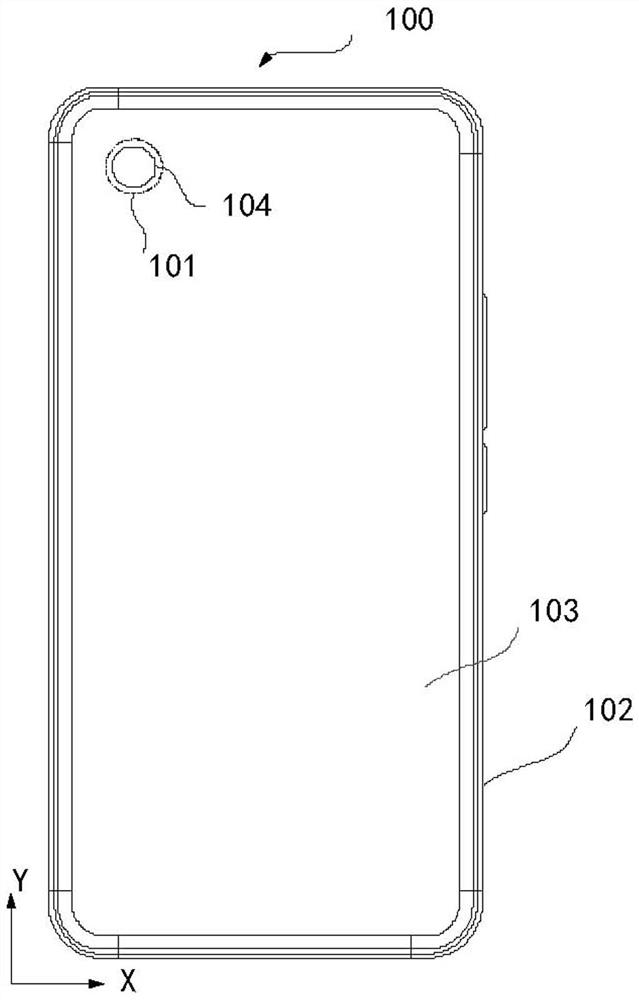

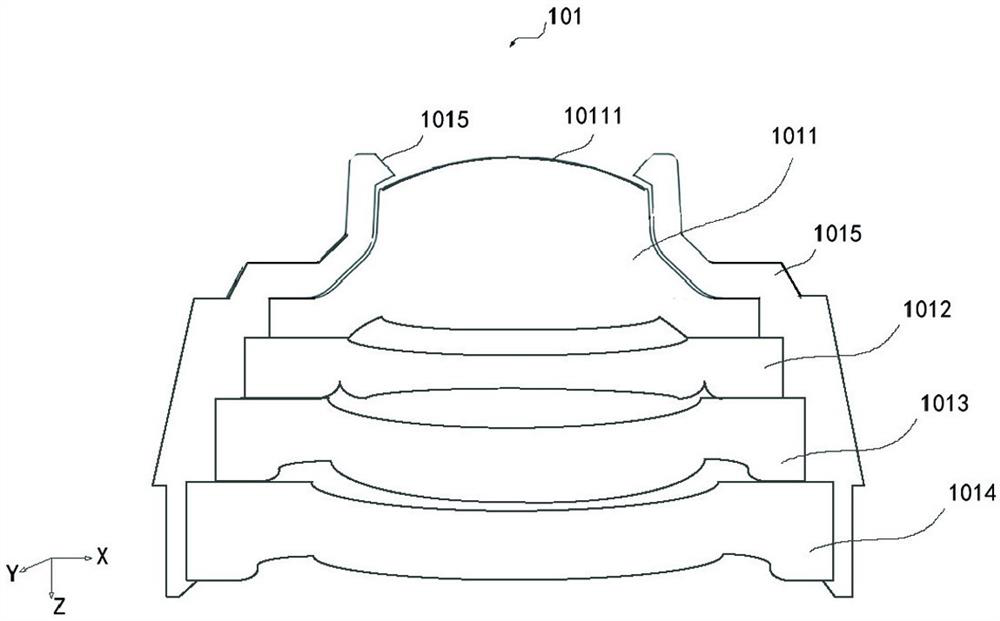

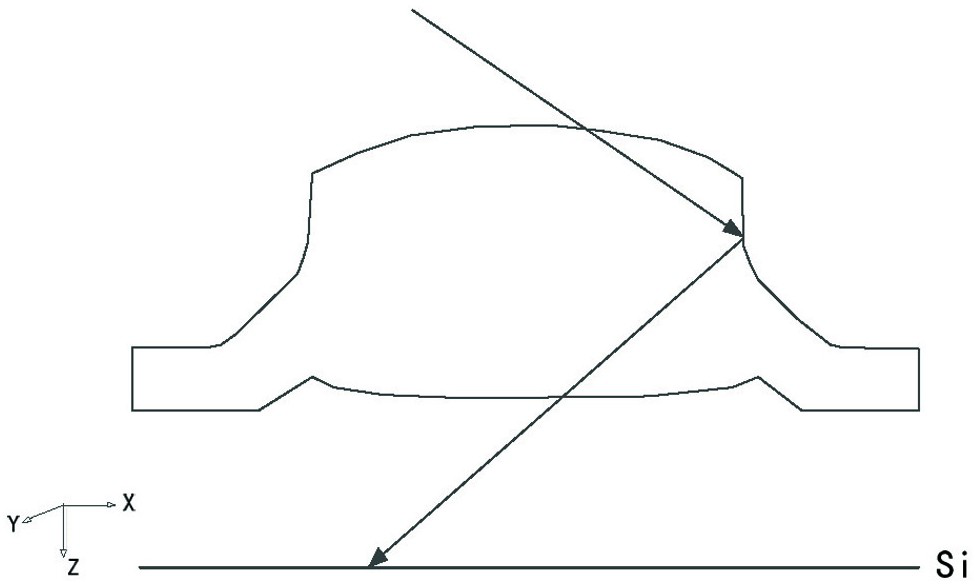

[0094] With the popularization of technology, more and more electronic devices have a shooting function. Specifically, in order to realize the shooting function of the electronic device, a lens module is arranged in the electronic device.

[0095] The embodiment of the present application does not specifically limit the type of electronic device, and the electronic device can be a mobil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com