Wire clamping device used for mechanical construction and capable of preventing fracture of insulating layer

An insulating layer, anti-break technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of reducing the quality of the card wire, inconvenient cable tension, reducing the effect of the card wire, etc., to improve the quality of the card wire, improve work efficiency, Improve the effect of card line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

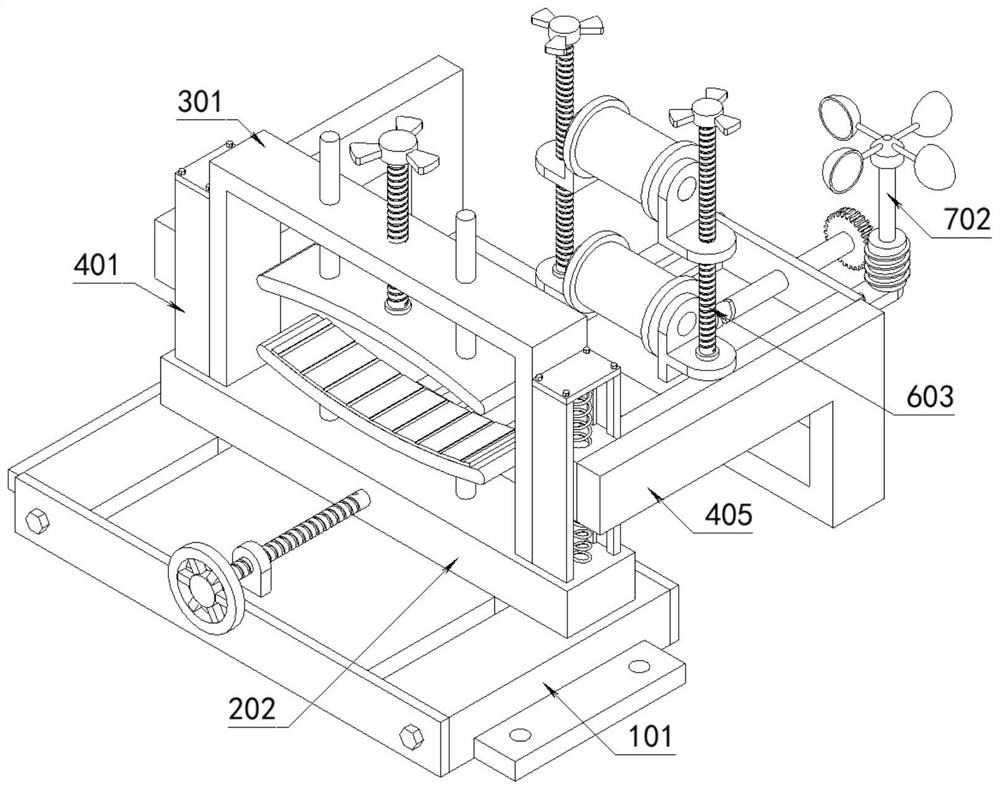

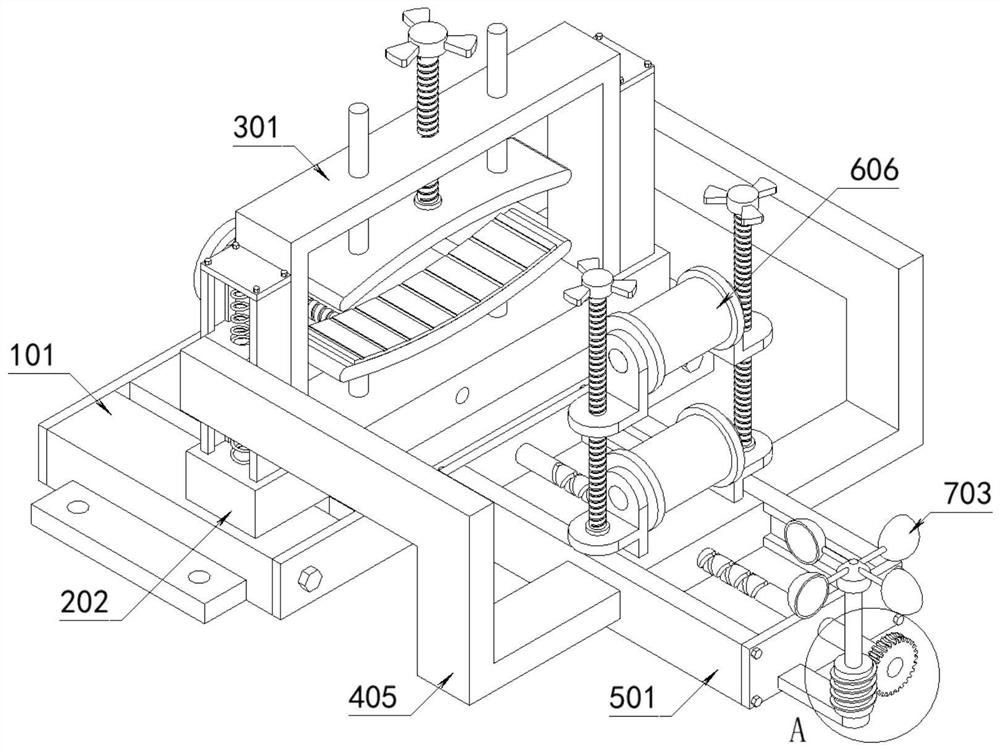

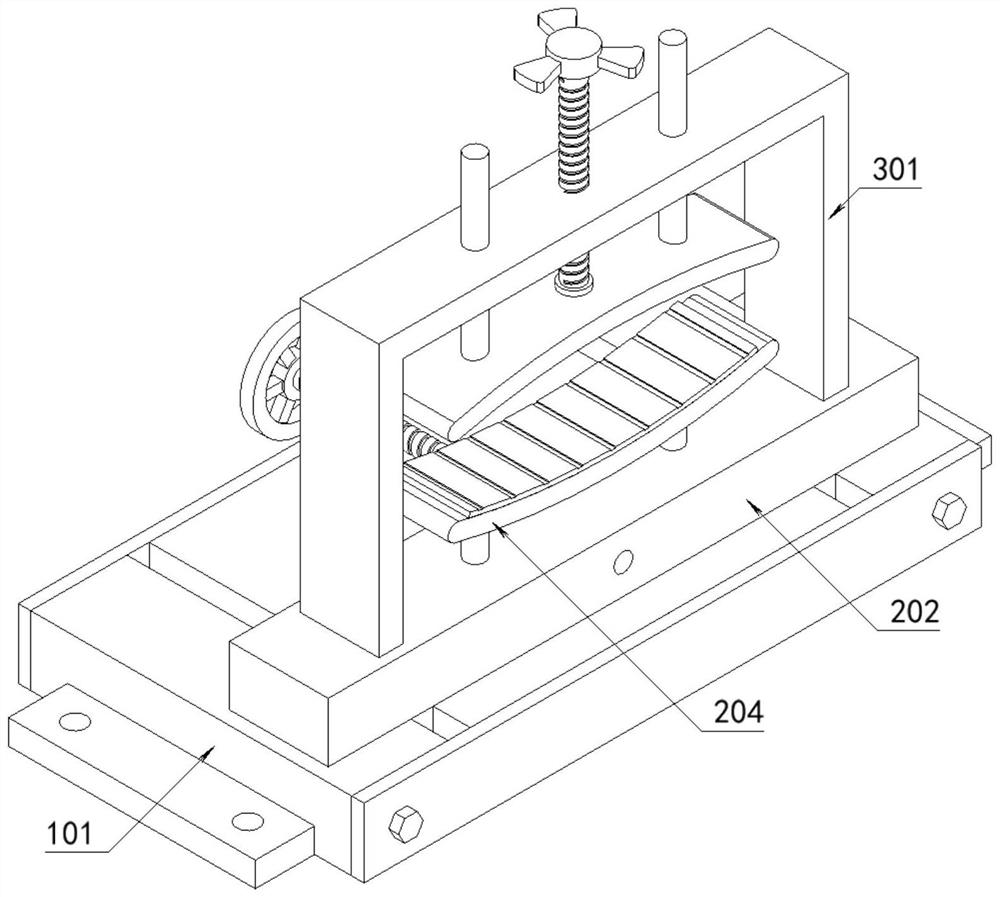

[0037] Example: Please refer to Figure 1 to Figure 12 :

[0038] The present invention proposes a wire clamping device for mechanized construction to prevent the breakage of the insulating layer, including a fixing device 1; a supporting device 2 is installed on the top of the fixing device 1, and a wire clamping assembly 3 is installed on the top of the supporting device 2; a connecting device 4 , there are two groups of connection devices 4, and the two groups of connection devices 4 are installed on the front and rear sides of the clamping assembly 3, and the installation assembly 5 is installed between the two groups of connection devices 4; the anti-breakage assembly 6, the anti-breakage assembly 6 It is installed on the top of the installation assembly 5, and the drive mechanism 7 is installed on the right side of the installation assembly 5.

[0039] In addition, according to an embodiment of the present invention, as Figure 4 to Figure 6 As shown, the fixing device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com