Cherry tomato picking method and cherry tomato picking manipulator

A technology of cherry tomatoes and manipulators, applied in picking machines, manipulators, program-controlled manipulators, etc., can solve the problems of low efficiency, small spacing, low picking efficiency, etc., and achieve high efficiency and good integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

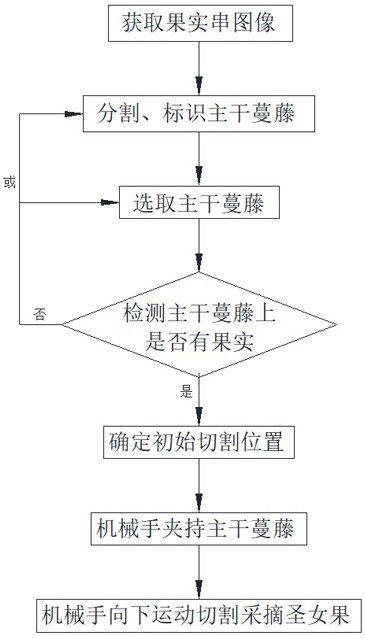

[0032] see Figure 1-Figure 3 , the present embodiment discloses a method for picking cherry tomatoes, comprising the following steps:

[0033] (1) Shoot the virgin fruit tree through the shooting device to obtain the image of the fruit string to be picked, such as figure 2 As shown; the shooting device in this embodiment includes a depth camera.

[0034] (2) The real-time segmentation model in the control recognition system analyzes and recognizes the images of the fruit clusters to be picked, and segments the main vines for specific identification. Specifically, the real-time segmentation model is the SOLOv2 model, which has the advantages of being dynamic, faster and stronger, and can quickly and accurately complete the segmentation and identification of the main vine in the fruit bunch image. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com