Jack guide sleeve tightening machine

A technology for guide sleeves and jacks, which is applied in the direction of hand-held tools, workpiece clamping devices, manufacturing tools, etc., and can solve the problems of inability to guarantee the thread tightening effect and pre-tightening force of guide sleeves, low production efficiency and assembly quality of jacks, and high labor intensity etc. to achieve the effect of reducing labor intensity of workers, improving tightening efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific working processes are provided, but the protection scope of the present invention is not limited to the following Described embodiment.

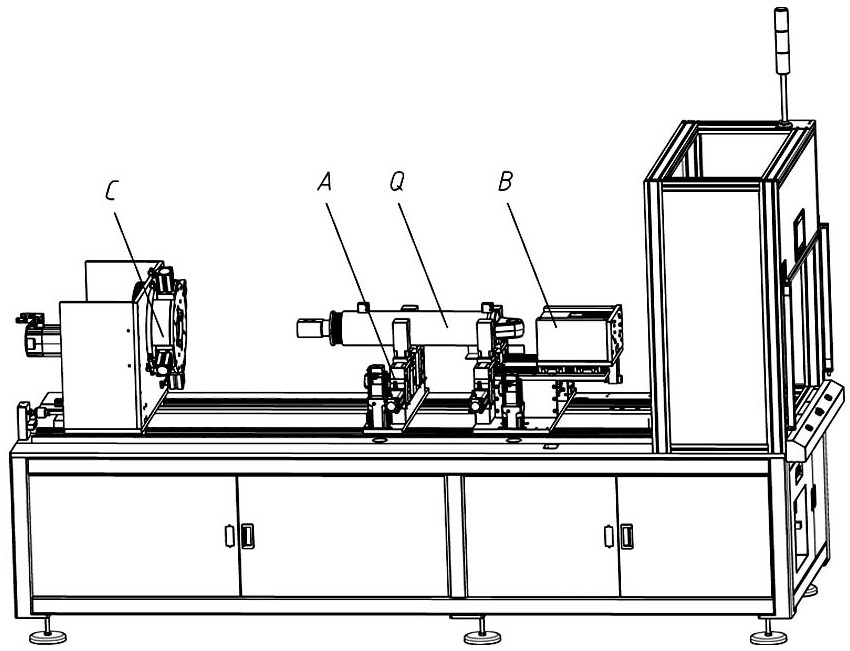

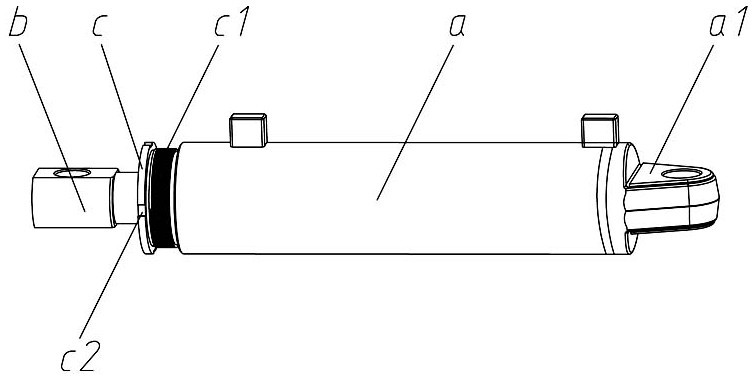

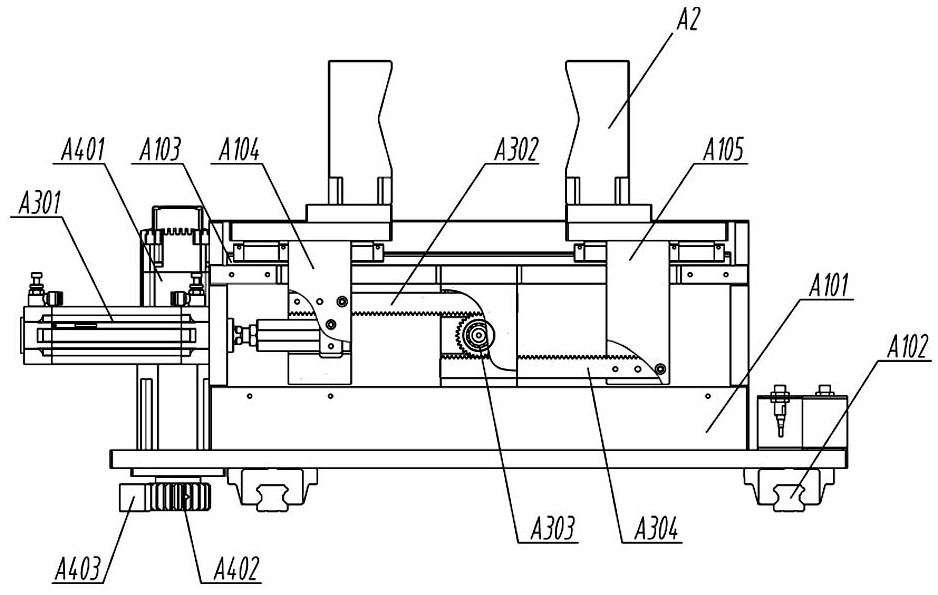

[0042] Such as Figure 1-6 As shown, the jack guide sleeve tightening machine according to the present invention is composed of a clamping mechanism A, a non-rotating mechanism B and a tightening mechanism C arranged on the console. It is suitable for the jack Q which is assembled with cylinder a and piston rod b (see figure 2 ), wherein, the head of the cylinder a is provided with an internal thread c1 that is compatible with the guide sleeve c, the tail of the cylinder a is provided with a pin hole ear a1, and the outer edge of the flange of the guide sleeve c is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com