Automatic driving chassis drive-by-wire system of mining dump truck

A self-driving technology for dump trucks, applied in electric braking systems, electric vehicles, vehicle components, etc., can solve problems such as high failure rate, poor reliability, and poor control accuracy, so as to reduce hardware, reduce failure rate, and improve The effect of control accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

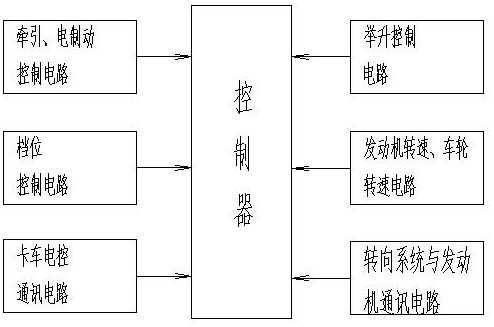

[0027] A control-by-wire system for an automatic driving chassis of a mining dump truck, which consists of: a controller, a traction and electric brake control circuit, a gear control circuit, a truck electronic control communication circuit, a lift control circuit, engine speed and wheel The speed circuit and the communication circuit between the steering system and the engine;

[0028] The traction and electric brake control circuit, the gear position control circuit, the truck electronic control communication circuit, the lift control circuit, the engine speed and wheel speed circuit and the steering The system and the engine communication circuit are respectively electrically connected to the controller;

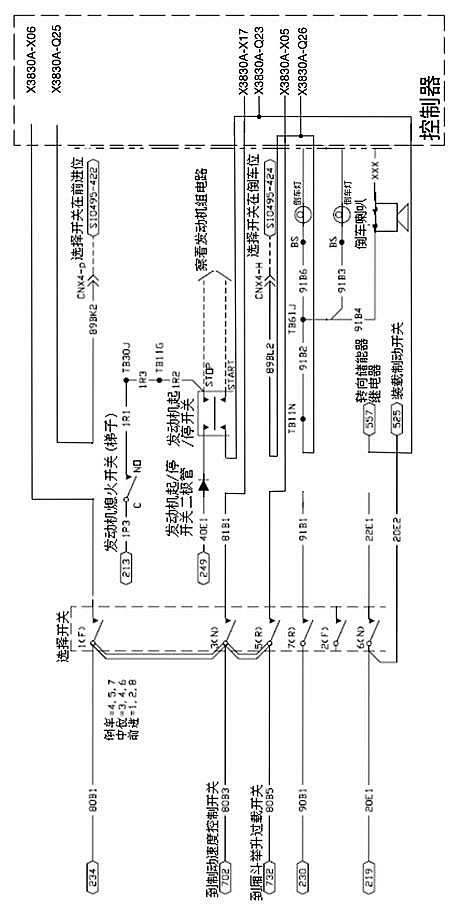

[0029] The gear position control circuit engine flameout switch, engine start / stop switch, selector switch, brake speed control switch and box lift overload switch, the brake speed control switch and the box lift overload switch The switches are respectively electricall...

Embodiment 2

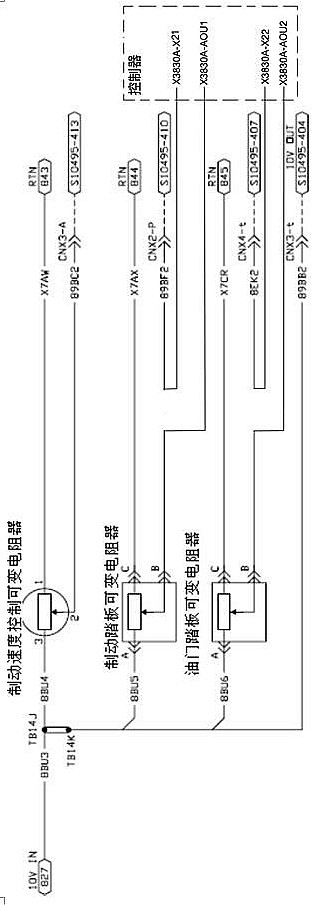

[0032] According to the mining dump truck automatic driving chassis wire control system described in Embodiment 1, the traction and electric braking control circuit includes a braking speed control variable resistor and a brake pedal variable resistor connected in parallel and gas pedal variable resistor.

Embodiment 3

[0034] According to the mine dump truck automatic driving chassis control-by-wire system described in Embodiment 1 or 2, the front wheel angle sensor is installed on the end cover of the vertical shaft of the front wheel or on the power steering cylinder.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap