Straight material up-row bent frame with high-adaptability feeding for aluminum profiles and implementation method of straight material up-row bent frame

An aluminum profile and adaptive technology, applied in the field of shelving, can solve the problems of low work efficiency, uncontrollable height, and increased land area, so as to achieve the effects of reducing land area, improving work efficiency, and improving storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

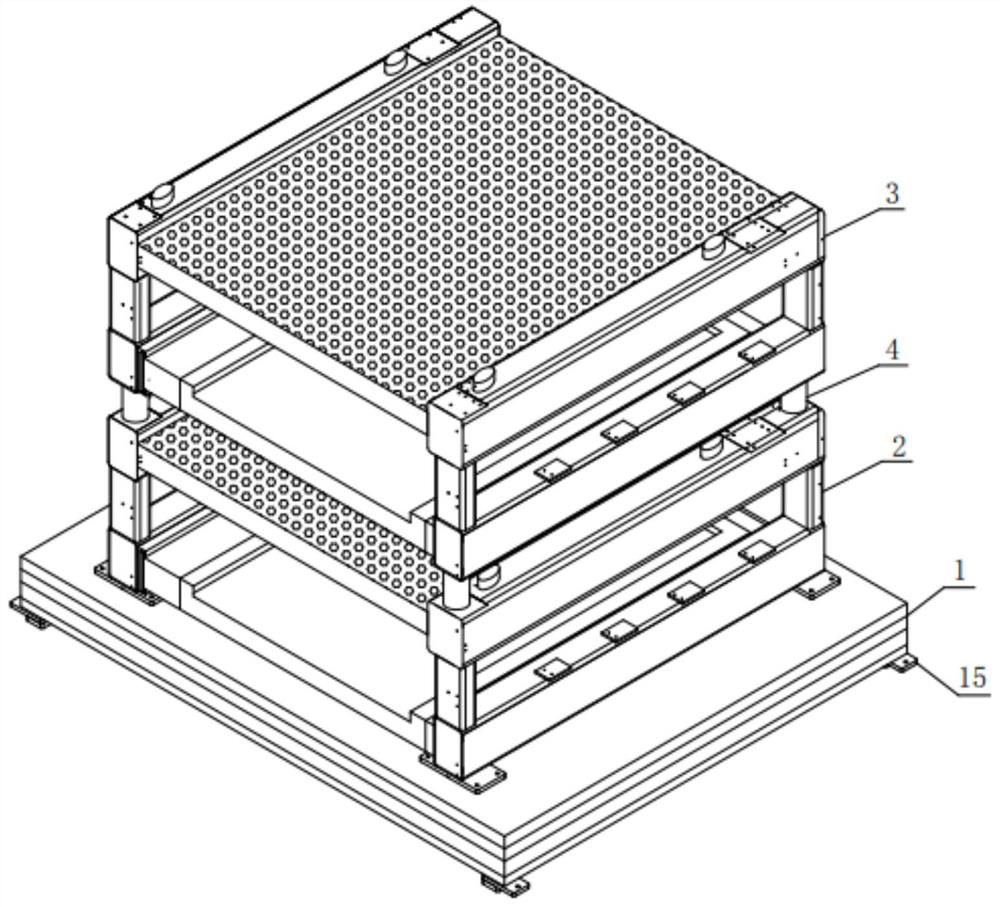

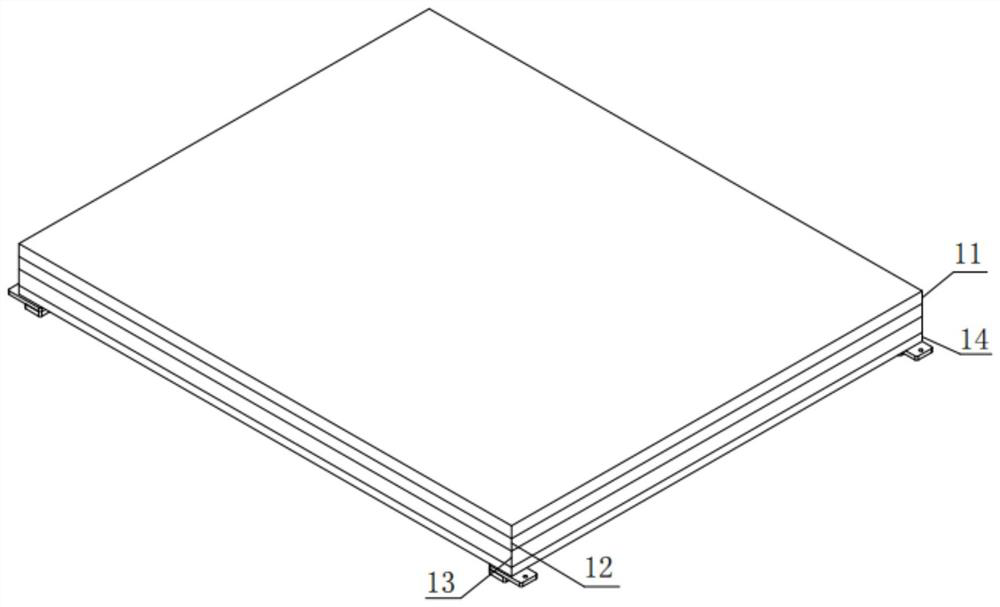

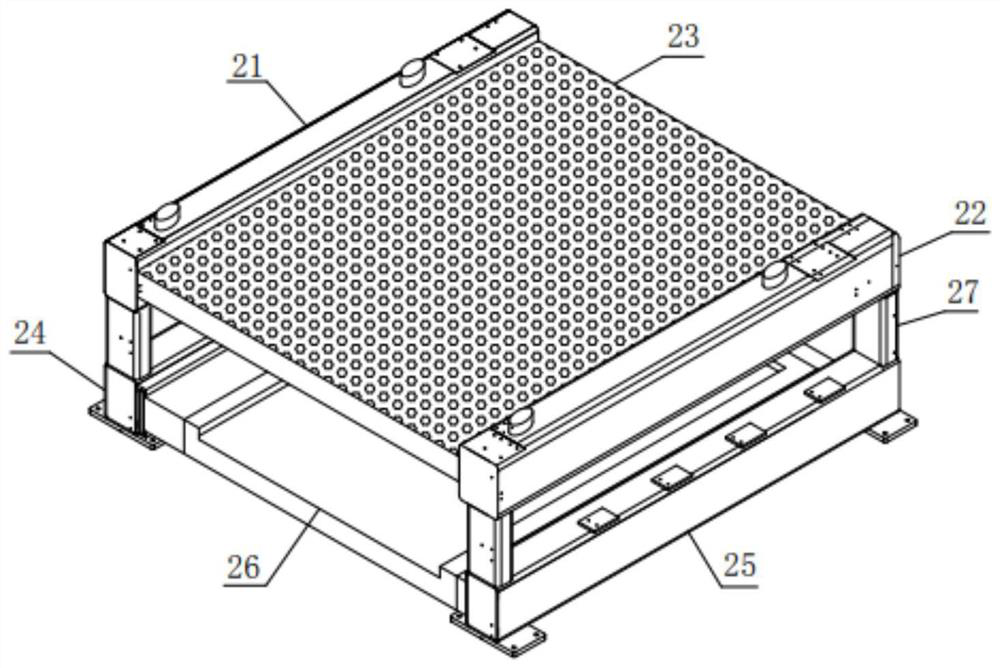

[0044] see Figure 1-8 , aluminum profile with high adaptability to the straight material upper rack, including the base plate 1, the first rack 2 and the second rack 3, where the upper end of the base plate 1 is installed with the first rack 2, the first row The second bent frame 3 is installed on the upper end of the frame 2, and the second bent frame 3 is connected with the first bent frame 2 through the lifting rod 4. When it is necessary to place aluminum profiles on the second bent frame 3, only the second bent The rack 3 can be put down, and the height can be adjusted according to the outer wall controller at will. It can be applied to various working environments, has strong practical performance, and can reduce the cumbersomeness of placing aluminum profiles in the past, greatly improving work efficiency. At the same time, the second rack 3. The upper end can still be stacked with bent racks. The placed structure is the same as that of the second bent rack 3 and the f...

Embodiment 2

[0049] see Figure 1-10 , aluminum profile with high adaptability to the straight material upper rack, including the base plate 1, the first rack 2 and the second rack 3, where the upper end of the base plate 1 is installed with the first rack 2, the first row The second bent frame 3 is installed on the upper end of the frame 2, and the second bent frame 3 is connected with the first bent frame 2 through the lifting rod 4. When it is necessary to place aluminum profiles on the second bent frame 3, only the second bent The rack 3 can be put down, and the height can be adjusted according to the outer wall controller at will. It can be applied to various working environments, has strong practical performance, and can reduce the cumbersomeness of placing aluminum profiles in the past, greatly improving work efficiency. At the same time, the second rack 3. The upper end can still be stacked with bent racks. The placed structure is the same as that of the second bent rack 3 and the ...

Embodiment approach

[0053] The implementation method of the straight material upper row rack with high adaptability for feeding aluminum profiles includes the following steps:

[0054] The first step: when the aluminum profile needs to be put into the bent shelf, the shelf plate connecting block 261 is slid out from the special-shaped groove 252 through the external controller;

[0055] Step 2: After the shelf plate connecting block 261 slides out, put the aluminum profile into the shelf groove 262;

[0056] Step 3: After the shelf board 26 in the first rack 2 is full of goods, the goods can be placed in the second rack 3;

[0057] Step 4: The first bent frame 2 and the second bent frame 3 can be lifted and lowered by the lifting rod 4 .

[0058]To sum up, this aluminum profile uses a straight material upper row shelf with high adaptability for feeding and its implementation method. After the shelf slot 262 is moved out, the aluminum profile can be easily placed on the shelf slot 262. The first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap