Auxiliary crank arm device for moving diesel generator in workshop

A technology of diesel generator and crank arm, which is applied in the direction of lifting device, transportation and packaging, load hanging components, etc., can solve the problem that it is infeasible to remove the roof of the nuclear power plant building, and it is impossible to move the diesel generator used in the nuclear power plant and the large diesel generator equipment. and other problems, to achieve the effect of simple structure, convenient movement and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

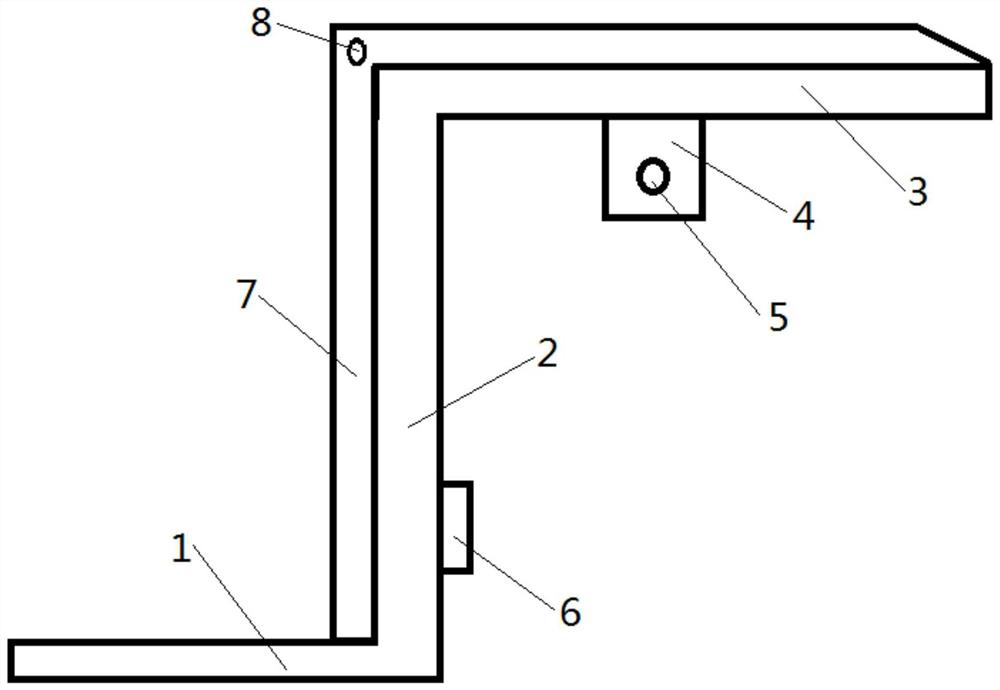

[0022] refer to figure 1 , this embodiment provides an auxiliary crank arm device for moving a diesel generator in a factory building, including a base 1, a vertical support frame 2, and a beam 3, the lower end of the vertical support frame 2 is connected to the base 1, and the The upper end of the vertical support frame 2 is connected with the crossbeam 3, and the crossbeam 3 extends downwards with a connection block 4, and the connection block 4 is provided with pin holes 5. When the auxiliary crank arm device is in use, the four The auxiliary crank arm device is installed at the four corners of the diesel generator, and the lifting lugs at the four corners of the diesel generator are connected to the pin holes 5 through pins, and the auxiliary crank arm device is realized by setting a hydraulic jack under the base 1 Lift together with diesel generator. At the same time, since the four corners all use auxiliary crank devices, the diesel generator can maintain a horizontal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com