Underwater anti-drag surface with gas production and capture alternating structure and preparation method of underwater anti-drag surface

A gas alternating and gas technology, which is applied in the field of underwater drag reduction surface and preparation with alternating structure of gas production and gas capture, can solve problems such as large energy consumption, and achieve the effects of low cost, uniform and stable gas generation, and continuous self-supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

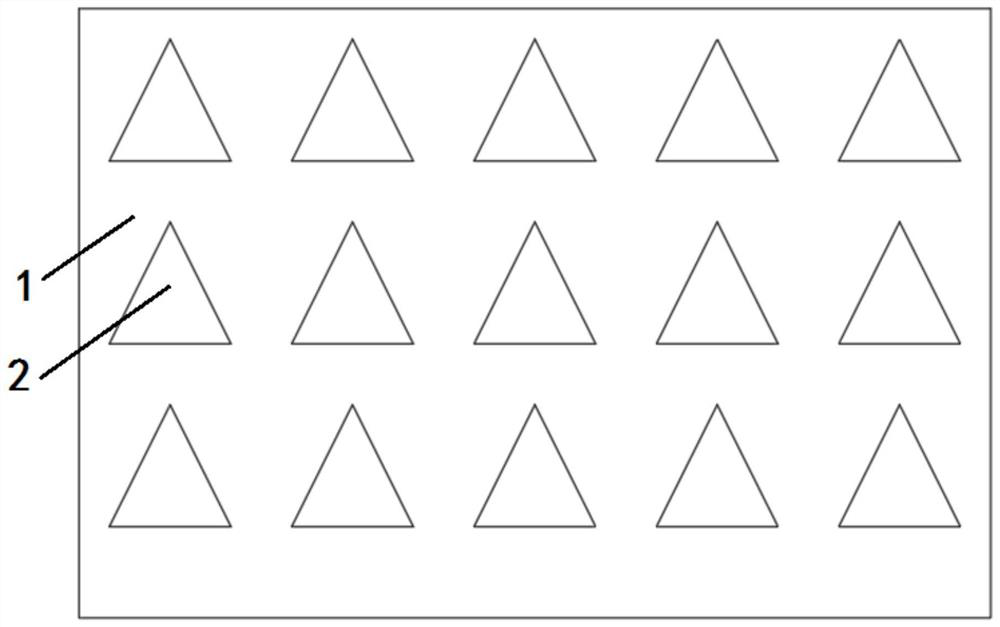

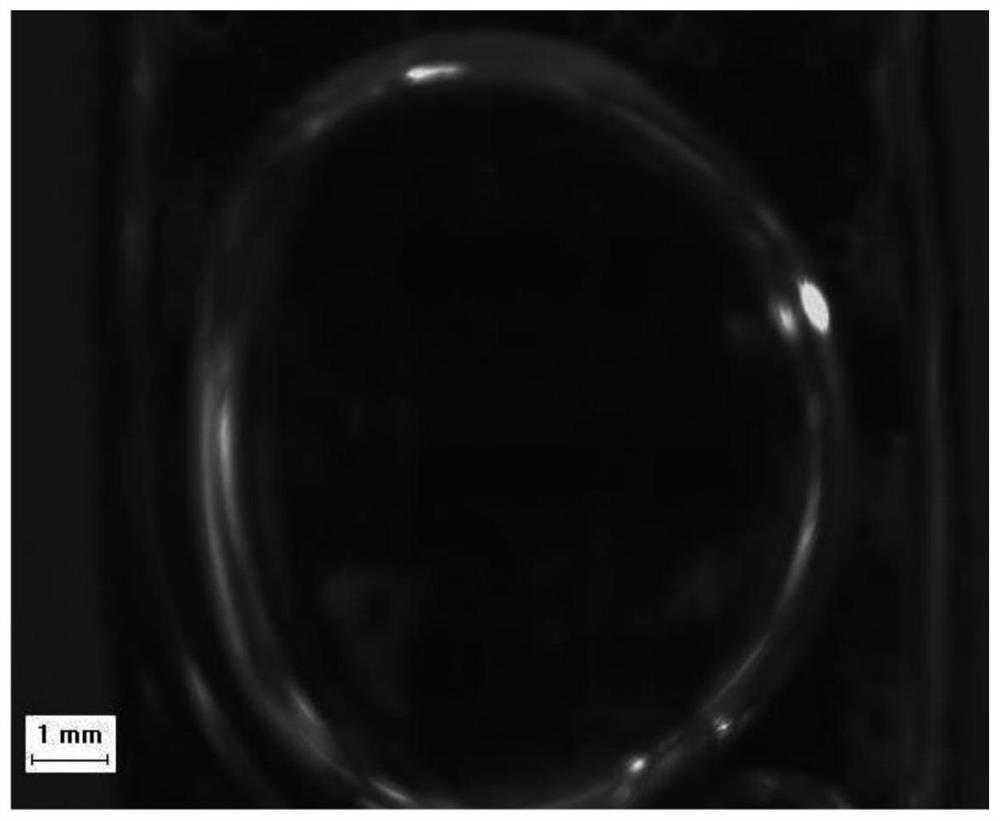

[0037] Such as Figure 1~3 As shown, an underwater drag reducing surface with alternating structure of gas production and gas capture, the drag reducing surface includes a substrate, the substrate is electrolyzed in a solution, the substrate is used as a cathode, and the solution can produce a solution of a gas, and a gas is generated at said substrate;

[0038] The solution may be an alkaline solution, such as potassium hydroxide solution, which generates hydrogen gas at the substrate during electrolysis.

[0039] The solution may be a neutral solution, such as sodium sulfate solution, which generates hydrogen gas at the substrate during the electrolysis process.

[0040] Described substrate is copper-nickel porous foam film 1 (as figure 2 Shown), the copper-nickel porous foam film 1 is fixed with a plurality of biaxially oriented polypropylene films (BOPP) 2, and there is a gap between two adjacent biaxially oriented polypropylene films 2, and the biaxially oriented polyp...

Embodiment 2

[0047] Such as Figure 1~3 As shown, a preparation method of an underwater drag-reducing surface with an alternating structure of gas production and gas capture, including:

[0048] (1) Cut the pure copper sheet into a rectangle of 15mm×10mm×0.2mm, polish it with 1000#, 2000#, 3000# sandpaper until it is bright, and use it as a working electrode.

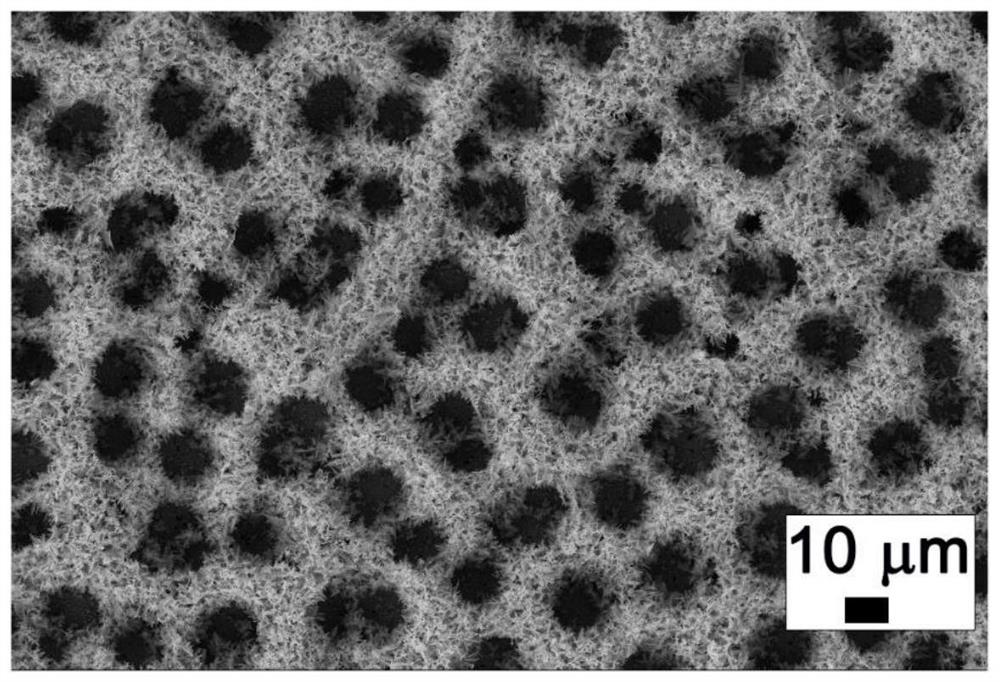

[0049] (2) NiSO with 0.5~1.0M (mol / L) 4 ·6H 2 O, 0.01~0.05M CuSO 4 ·5H 2 O, 1.5-2.0M H 2 SO 4 , 1~1.5M HCL is used as the electrolyte, a cylindrical platinum wire with a diameter of 0.5mm is used as the counter electrode, 3M KCL is used as the reference electrode, and 1~2A / cm 2 Electrochemical deposition of three systems was carried out on the working electrode with a current density of 100-150 s to obtain a copper-nickel porous foam film 1 with a pore size of 60-100 μm and a thickness of 50-100 μm (such as figure 2 shown), which is used as the substrate for underwater drag reduction and self-generation of gas.

[0050] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com