Special high-voltage cable for large electromechanical equipment

A technology for electromechanical equipment and high-voltage cables, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of inconvenient bending of cables, rupture and leakage, etc., achieve rapid air-cooled heat dissipation, comprehensive heat dissipation, and avoid rapid aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

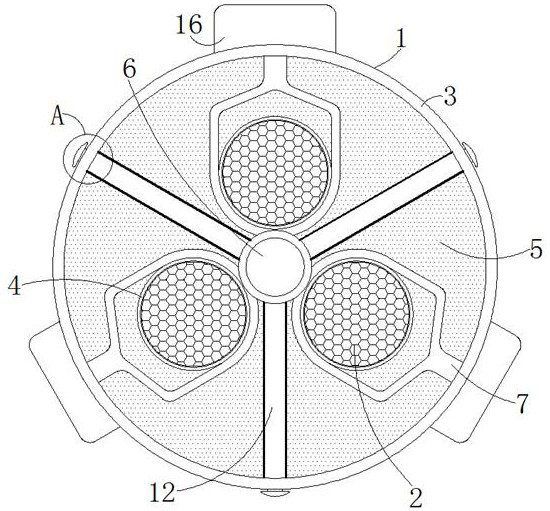

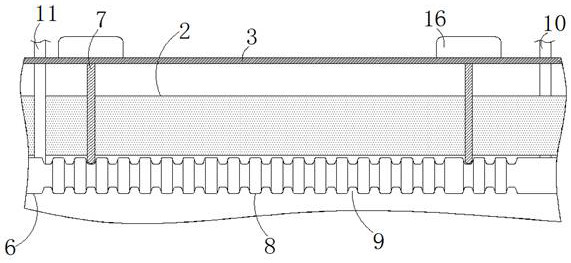

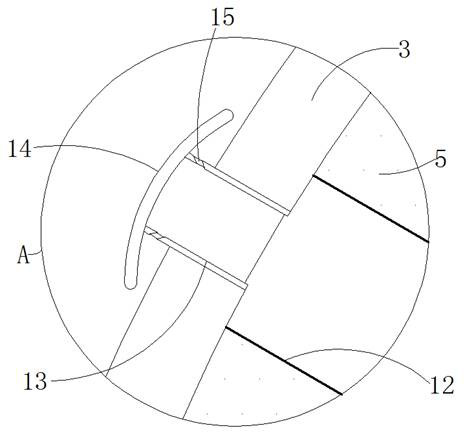

[0028] A special high-voltage cable for large-scale electromechanical equipment, including a cable body 1, a conductor 2, a sheath 3, an insulating layer 4 and a filling layer 5, the cable body 1 is composed of a sheath 3 and a conductor 2, and the conductor 2 contains a copper core and is wrapped in a The outer insulating layer 4, and the periphery of the conductor 2 is provided with a filling layer 5, and the filling layer 5 is located between the outer skin 3 and the conductor 2, and the outer side of the conductor 2 is provided with a surrounding distribution of heat conduction strips 7, and the inner wall of the heat conduction strip 7 and The outer walls of the insulating layer 4 are attached to each other, the center of the cable body 1 is provided with a flow pipe 6, and the pipe wall of the flow pipe 6 is provided with a raised portion 8 and a recessed portion 9, the recessed portion 9 is an elastic structure, and the recessed portion 9 The elastic deformation makes th...

no. 2 example

[0031] A special high-voltage cable for large-scale electromechanical equipment, including a cable body 1, a conductor 2, a sheath 3, an insulating layer 4 and a filling layer 5, the cable body 1 is composed of a sheath 3 and a conductor 2, and the conductor 2 contains a copper core and is wrapped in a The outer insulating layer 4, and the periphery of the conductor 2 is provided with a filling layer 5, and the filling layer 5 is located between the outer skin 3 and the conductor 2, and the outer side of the conductor 2 is provided with a surrounding distribution of heat conduction strips 7, and the inner wall of the heat conduction strip 7 and The outer walls of the insulating layer 4 are attached to each other, the center of the cable body 1 is provided with a flow pipe 6, and the pipe wall of the flow pipe 6 is provided with a raised portion 8 and a recessed portion 9, the recessed portion 9 is an elastic structure, and the recessed portion 9 The elastic deformation makes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com