Patents

Literature

36results about How to "Rapid air cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

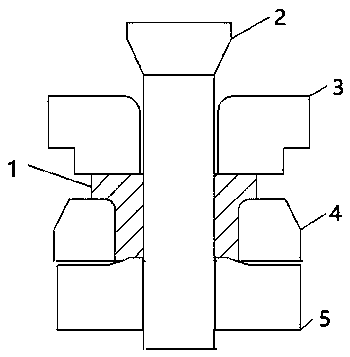

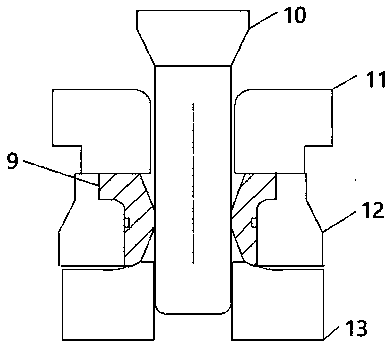

Forging method for outer ring or inner ring of double-row conical bearing

InactiveCN111531101AReduce the difficulty of subsequent processingSave raw materialsMetal-working apparatusPunchingManufactured material

The invention discloses a forging method for an outer ring or an inner ring of a double-row conical bearing. The forming method mainly includes the following steps of: a heading and back-extrusion step, a punching and leveling step, a reaming step and a shaping step. The forging method disclosed by the invention adopts a carbon steel material; an initial blank is forged and forming-forged; different forging molds with same proportion are adopted; and the advantages of the process reduce the subsequent machining difficulty of products and save raw materials.

Owner:冠县中圆轴承有限公司

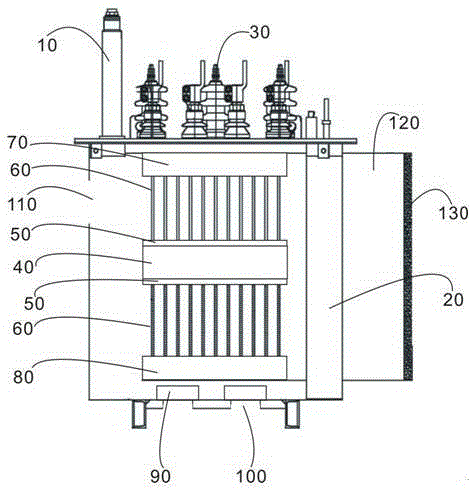

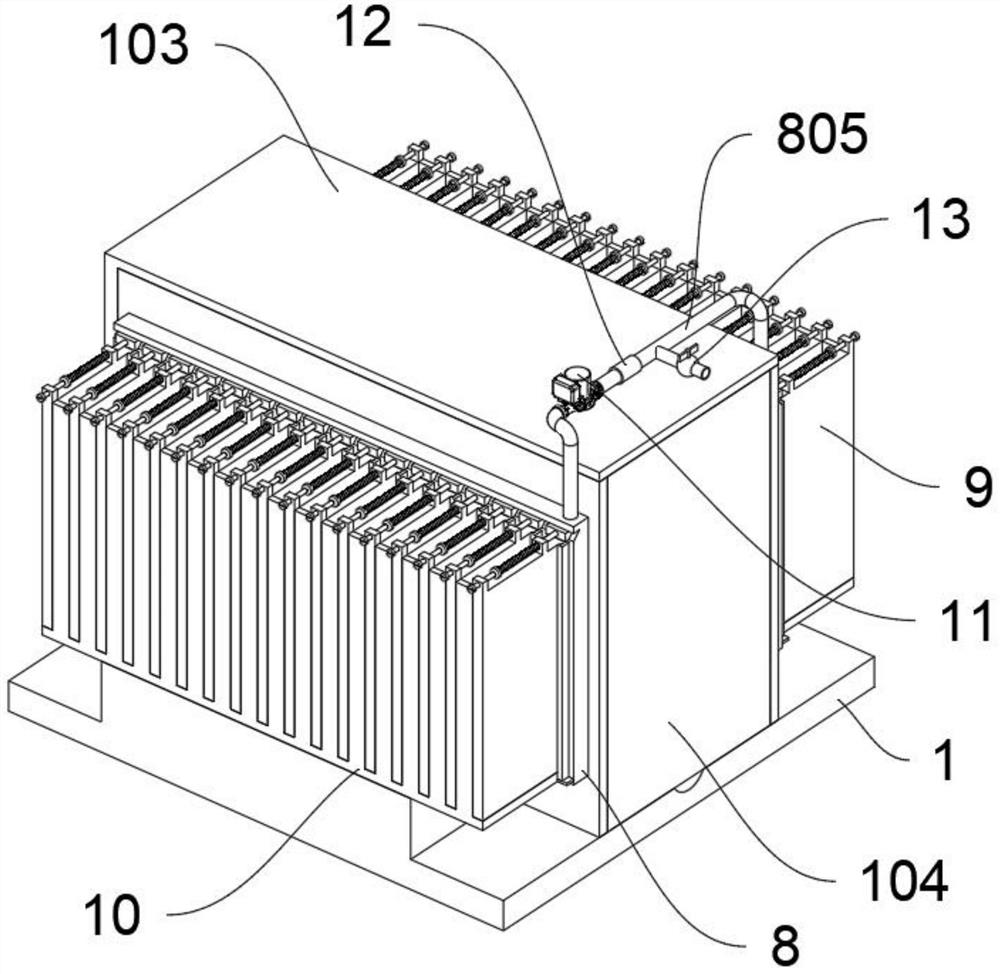

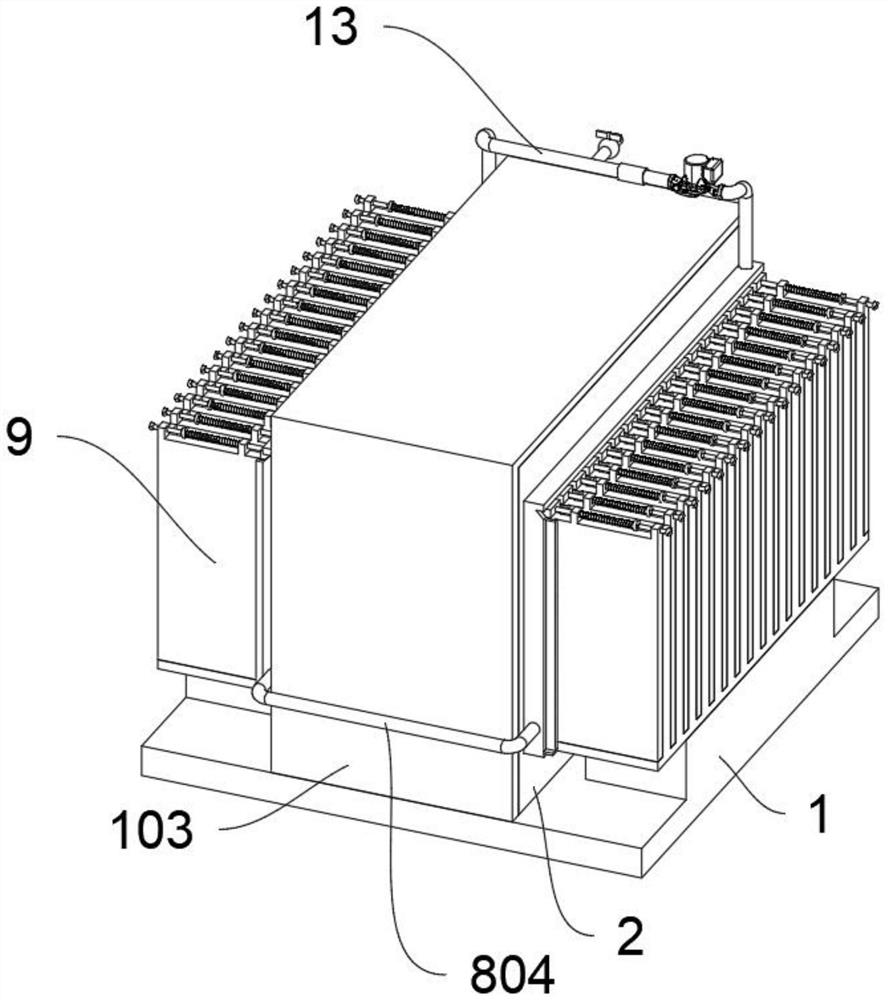

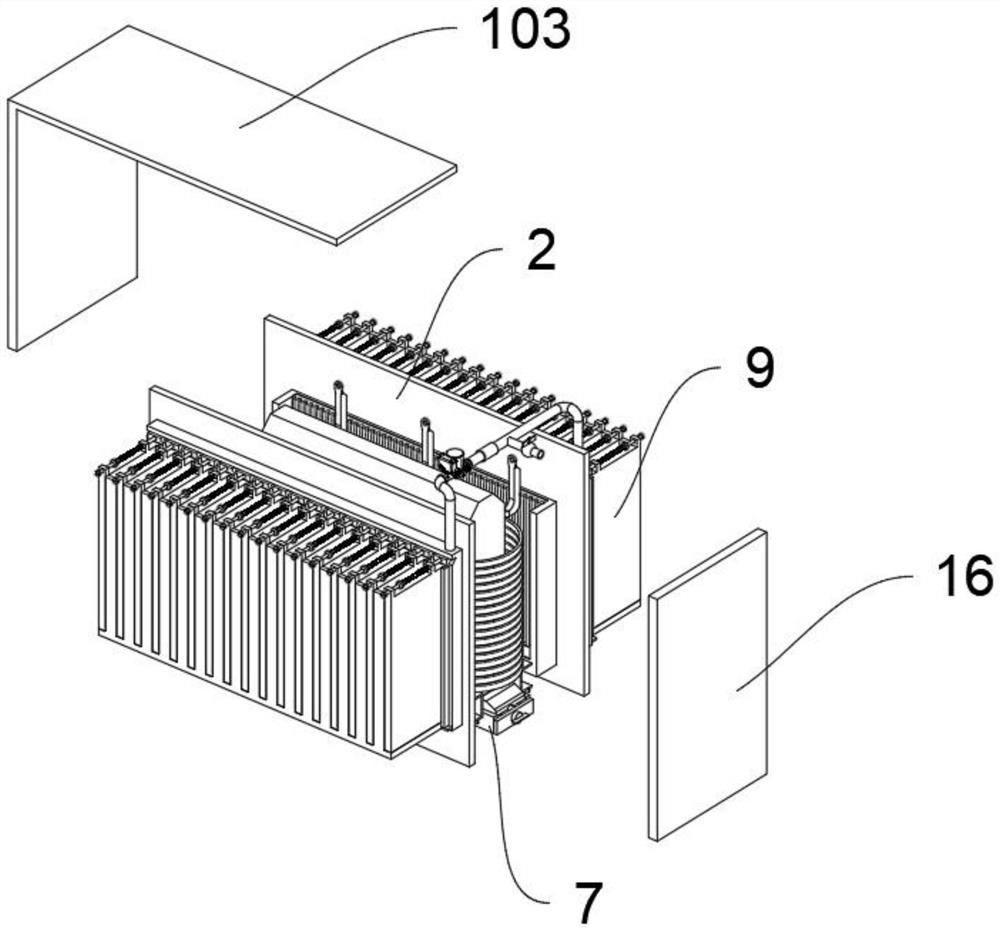

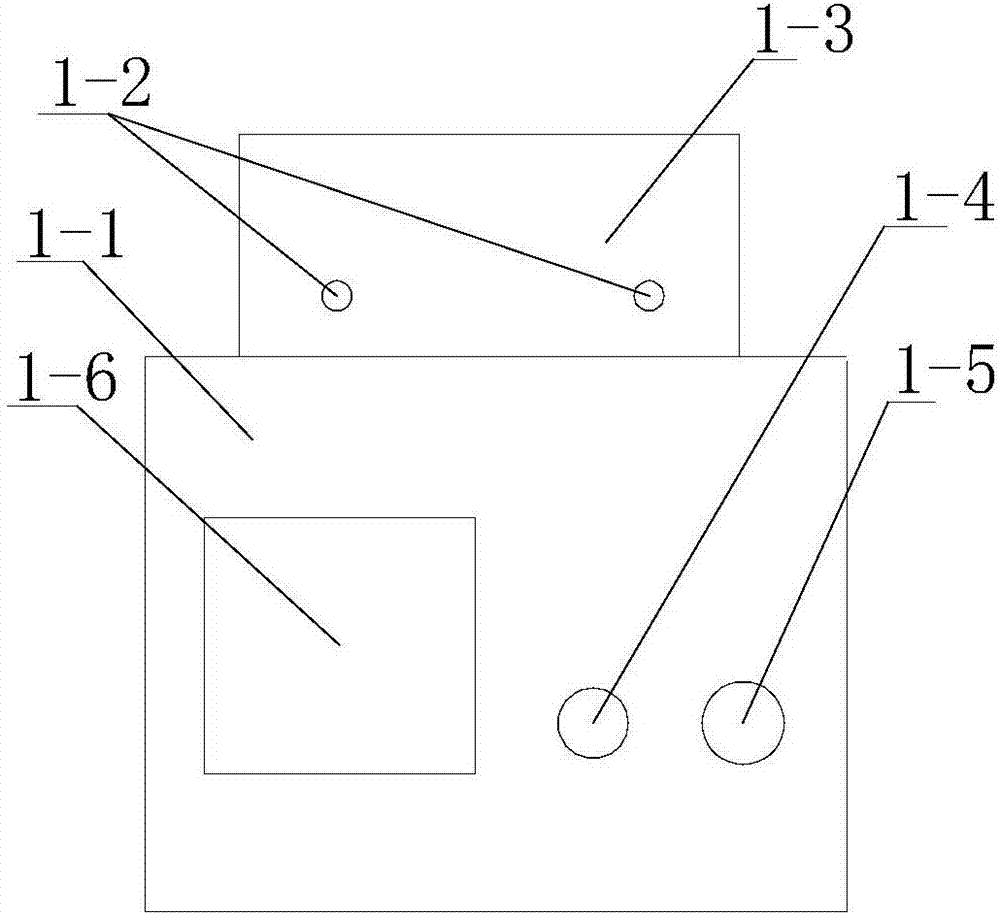

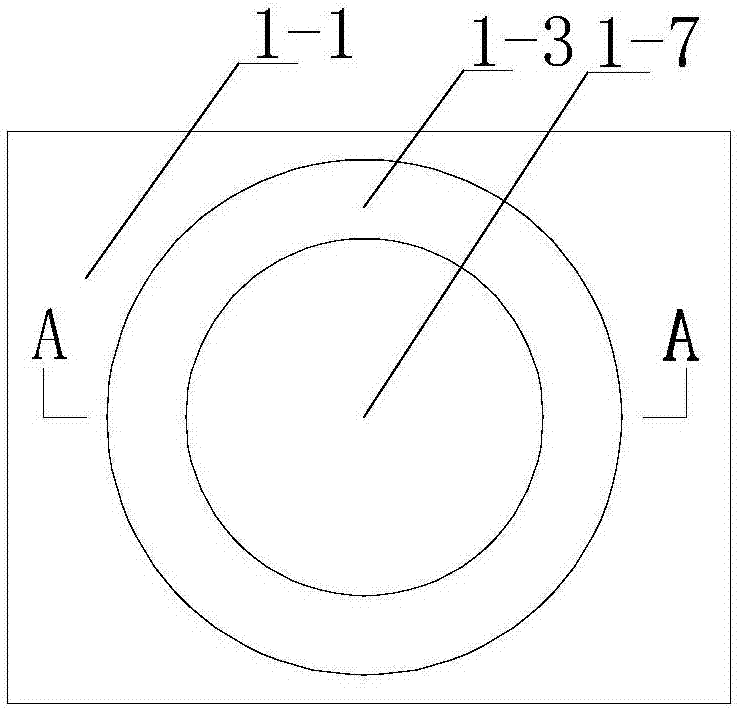

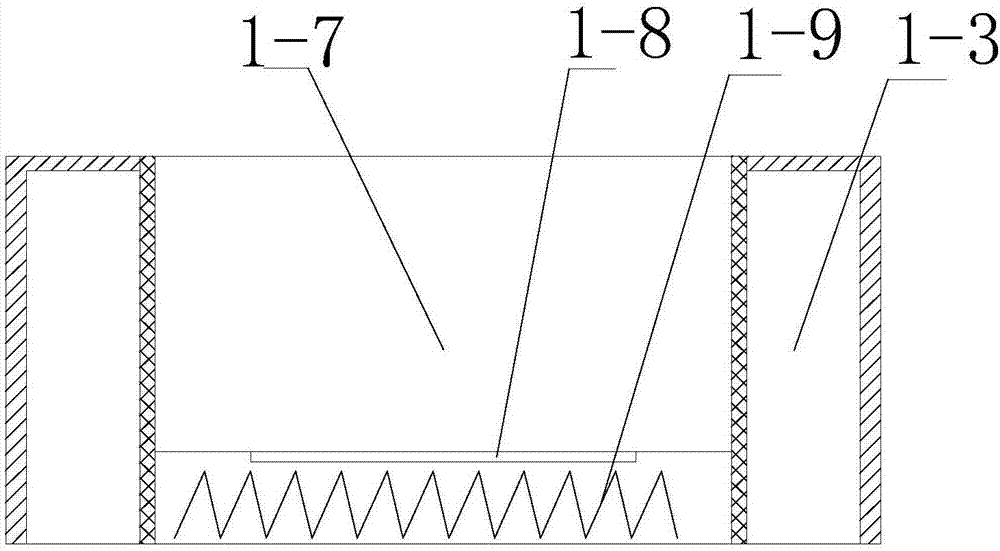

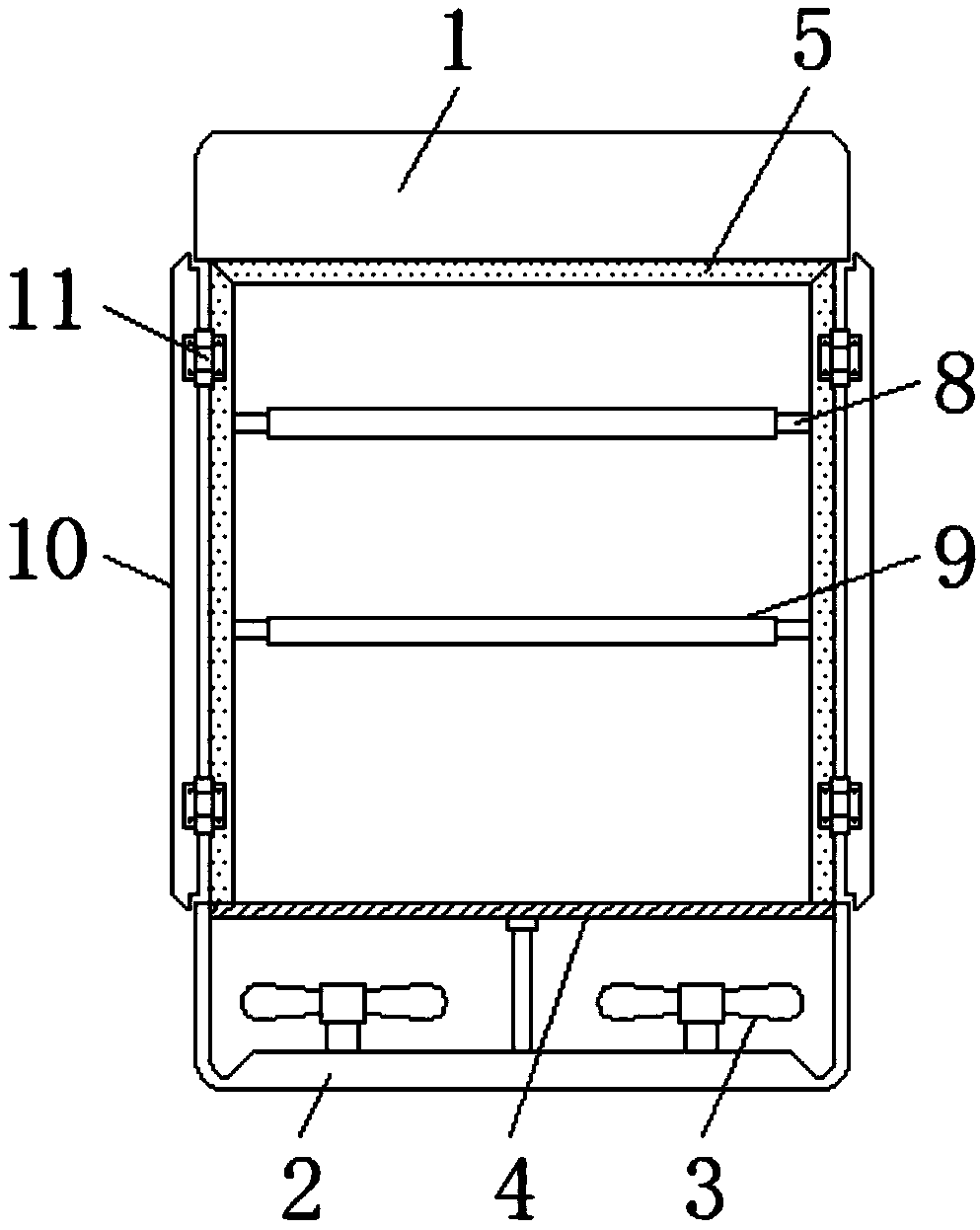

Oil-immersed power transformer

InactiveCN105405591ARapid air coolingReduce the temperatureTransformers/inductances coolingTransformerEngineering

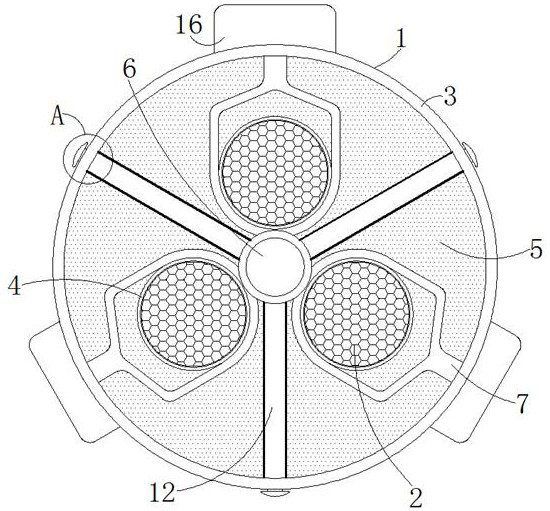

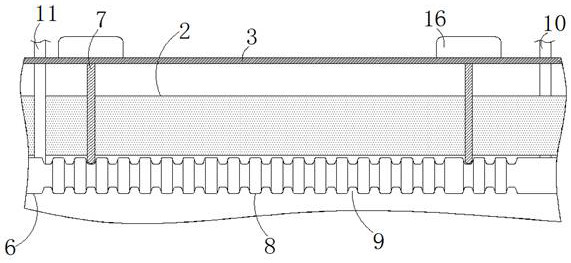

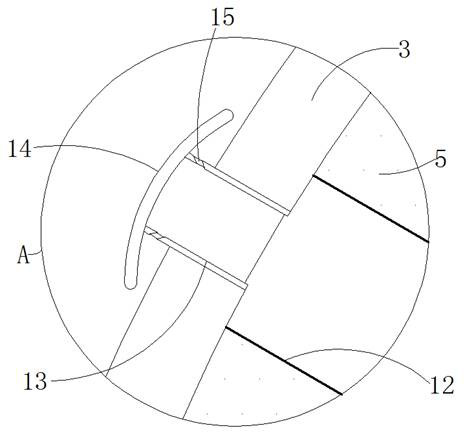

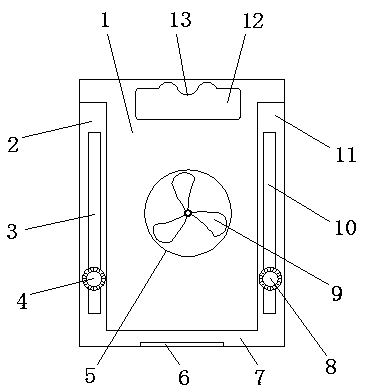

The invention provides an oil-immersed power transformer. The oil-immersed power transformer comprises a safety air channel, a transformer box, an insulating sleeve, a transformer body, a heat-exchanging tube, an upper condenser, a lower condenser, thermal conductive discs, and a heat-exchanging fan; the thermal conductive discs for performing heat conduction are arranged on the upper surface and the lower surface of the transformer body; the upper condenser is arranged above the transformer box; the lower condenser, an air inlet and the heat-exchanging are arranged below the transformer box; the upper condenser and the lower condenser are connected with the thermal conductive discs through the heat-exchanging tube; and at least an air outlet is formed in the side wall of the transformer box. The heat-exchanging tube can rapidly cool the heat absorbed by the thermal conductive discs through the upper condenser and the lower condenser; meanwhile, the air inlet below the transformer box, the heat-exchanging fan and the air outlet in the side wall can rapidly perform air cooling on the transformer so as to greatly reduce the temperature of the transformer, so that the service life and the safety performance of the transformer can be improved.

Owner:YANGZHOU GUORUI NEW ENERGY TECH CO LTD

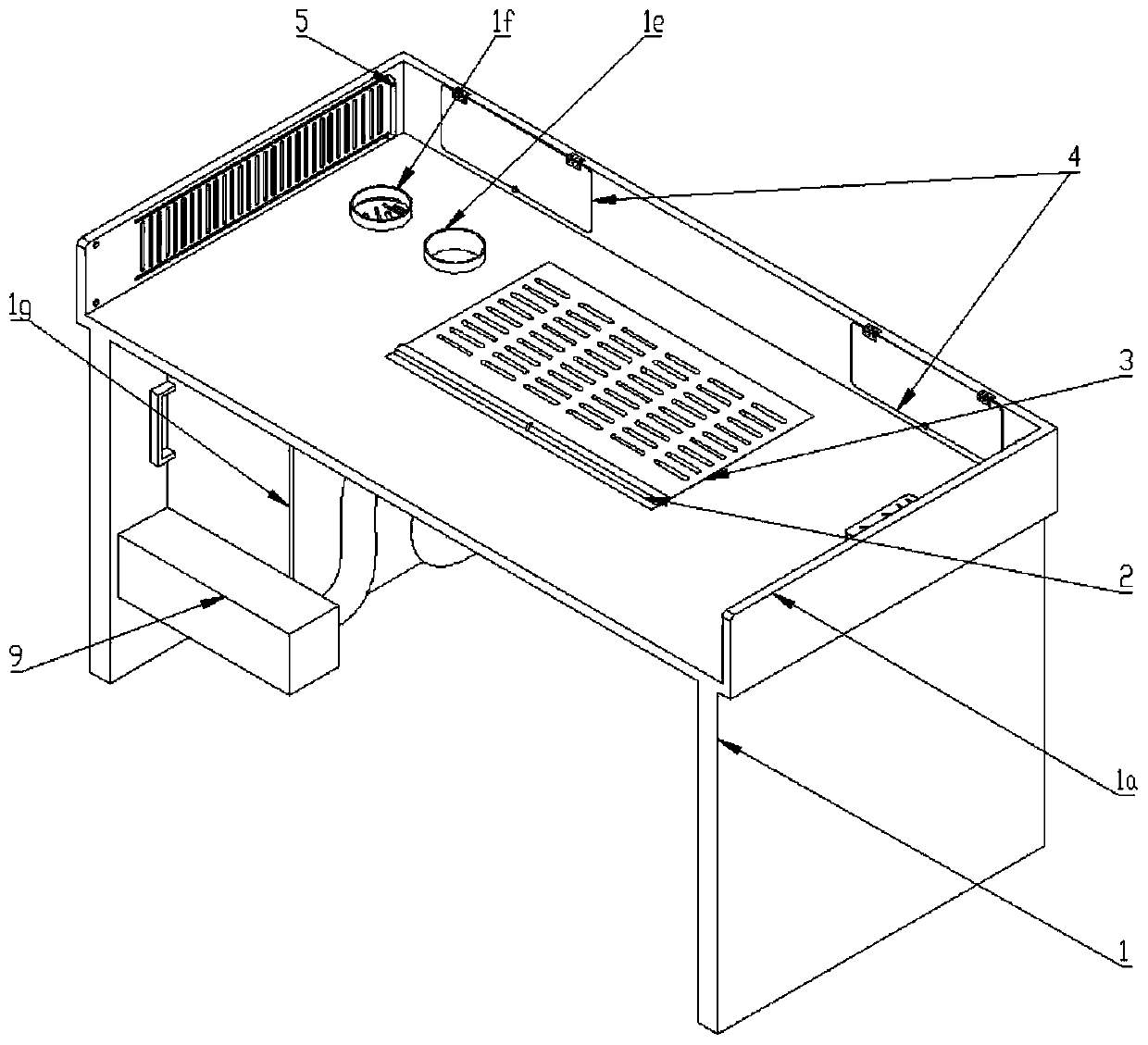

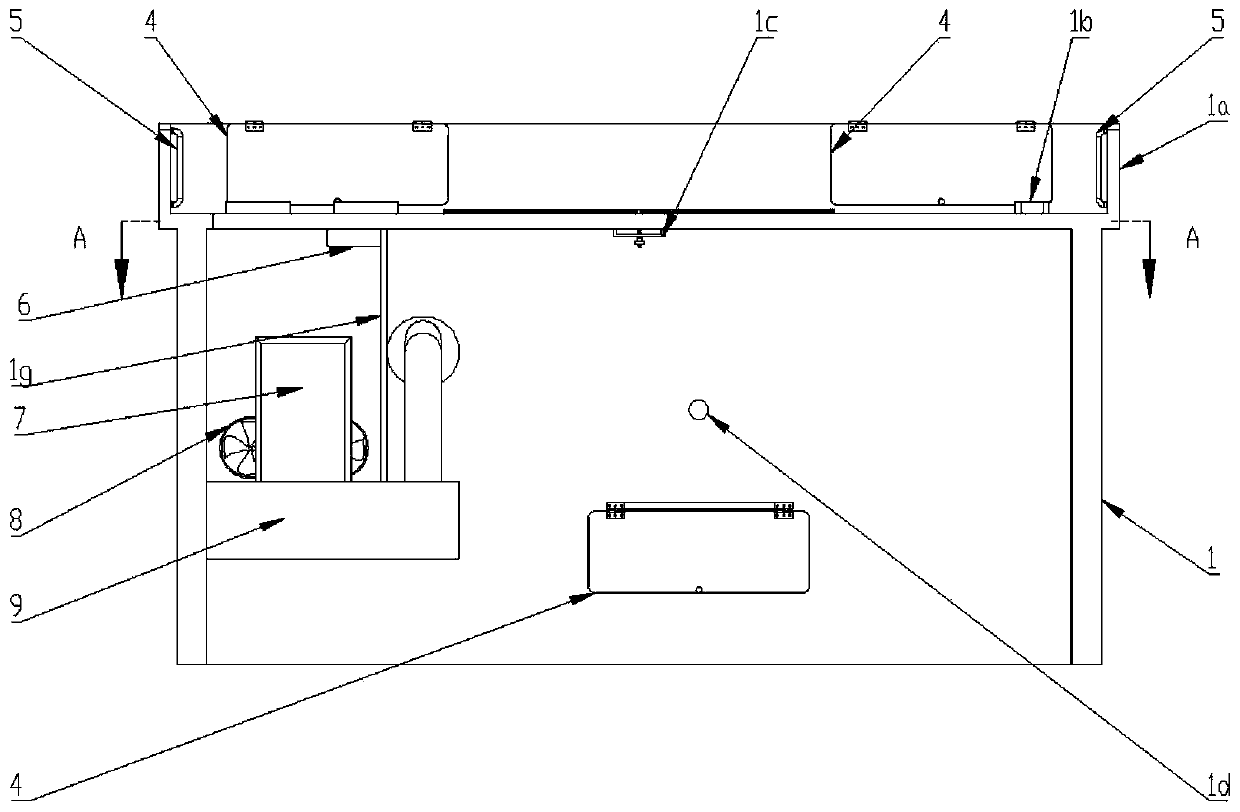

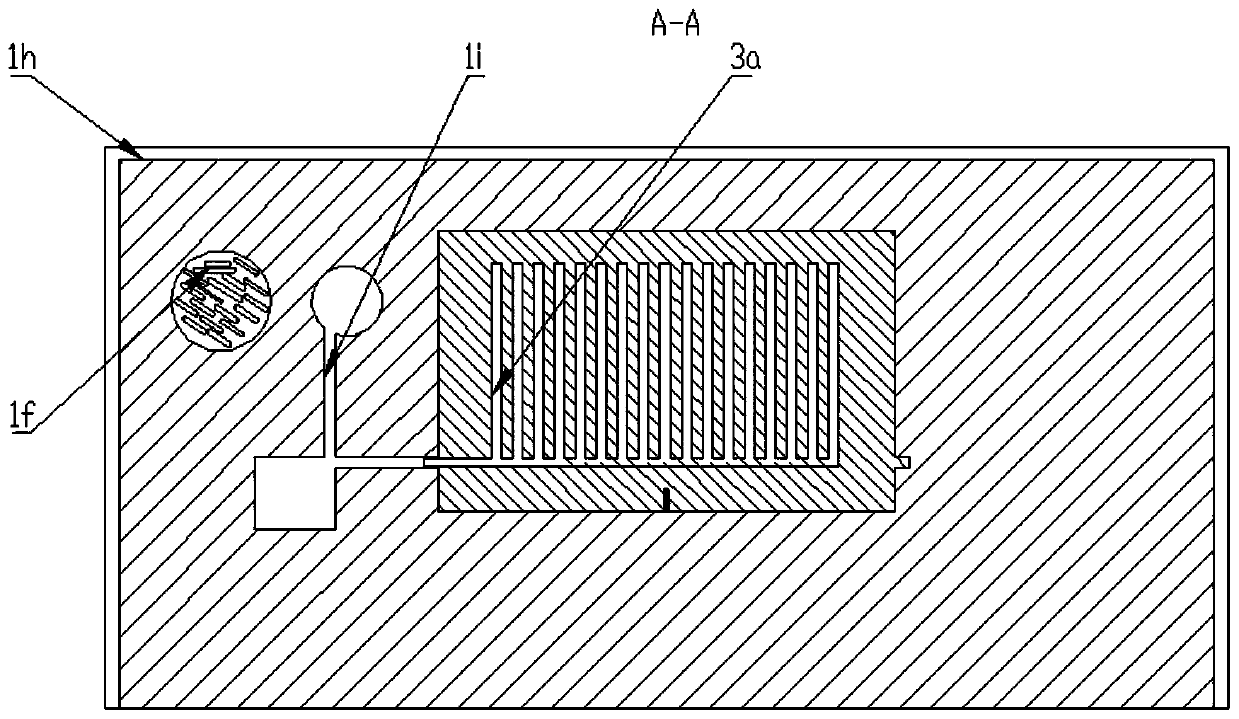

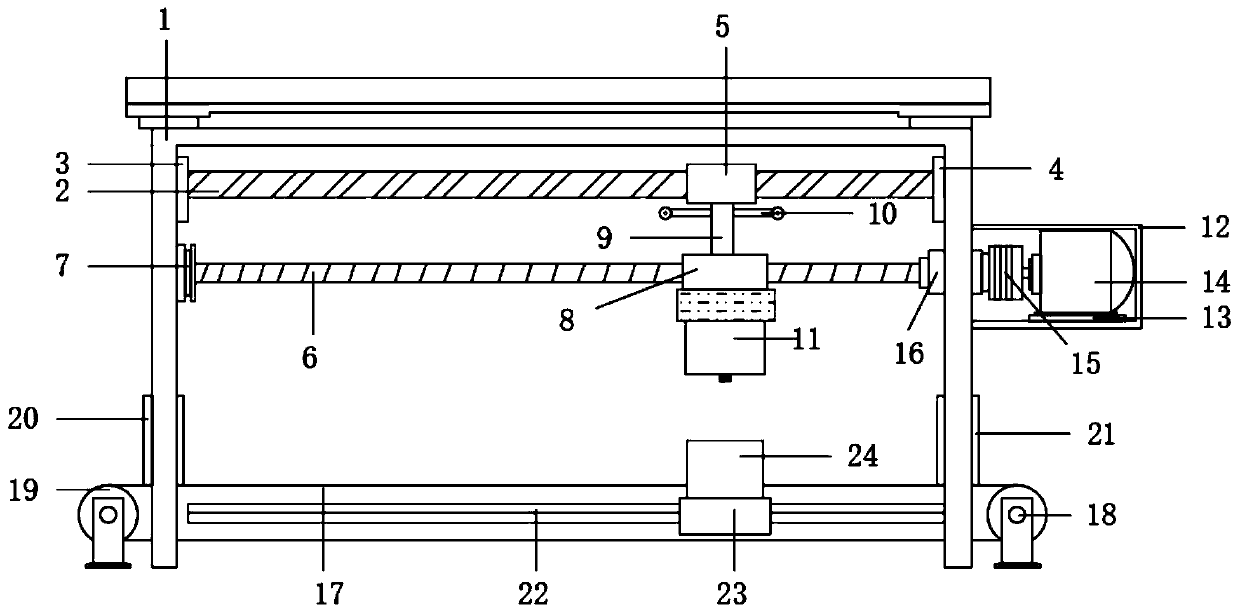

Office table capable of automatically controlling supply of cooling and heating

The invention relates to an office table capable of automatically controlling supply of cooling and heating, and can effectively solve the problems that the prior art cannot quickly cool down computerproducts, cannot provide cold air or warm air, and does not have a dust absorption function. The technical scheme is that the office table comprises a table body; baffles are fixed on three sides ofthe table top of the table body; the middle of the table top of the table body is provided with a flap hole; a flap is hinged inside the flap hole; a drag link mechanism is arranged on the flap; a plurality of air outlets are arranged on the table body and the baffles; folding wind shielding plates are slidably arranged at the air outlets on the two sides of the baffles; overturning wind shieldingplates are arranged on the baffles and the table body; the overturning wind shielding plate on the table body is located directly in front of the air outlet on the table body; and the table body is fixedly provided with a placing box under the table top. According to the office table capable of automatically controlling supply of cooling and heating provided by the invention, a display screen ofa computer host can be quickly subjected to air cooling, an air supply mechanism can be selected for heating or cooling, a dust collecting mechanism performs dust collection while heating and cooling,thus the office table is energy-saving and environment-friendly, and is an innovation on office tables.

Owner:ZHENGZHOU UNIV +1

Casting part isolation cooling device

The invention discloses a casting part isolation cooling device. The casting part isolation cooling device comprises a cooling box, wherein the outer side surface of the cooling box is provided with atransparent observation window, a first box door is arranged below one side of the cooling box, a second box door is arranged on the other side, away from the first box door, of the lower part of thecooling box, and a horizontal conveying belt is arranged below the first box door and the second box door. By arranging a water spraying and cooling mechanism capable of horizontally moving, sprayingand cooling can be conducted on the casting part which moves on the horizontal conveying belt, and rapid refrigeration can be achieved when the spraying and cooling are undergoing according to the principle that a refrigerant vaporizes and absorbs heat. A evaporation pipe is vertically arranged on one side of a fan, and cold air is blown to the horizontal conveying belt by a fan blade while the refrigerating is undergoing uniformly, therefore the casting part can be rapidly blown and cooled. The casting part isolation cooling device has the advantages of simple structure, high efficiency, easy repairing and maintaining and less workload for constructors, thus greatly improving the operation efficiency.

Owner:夏成雷

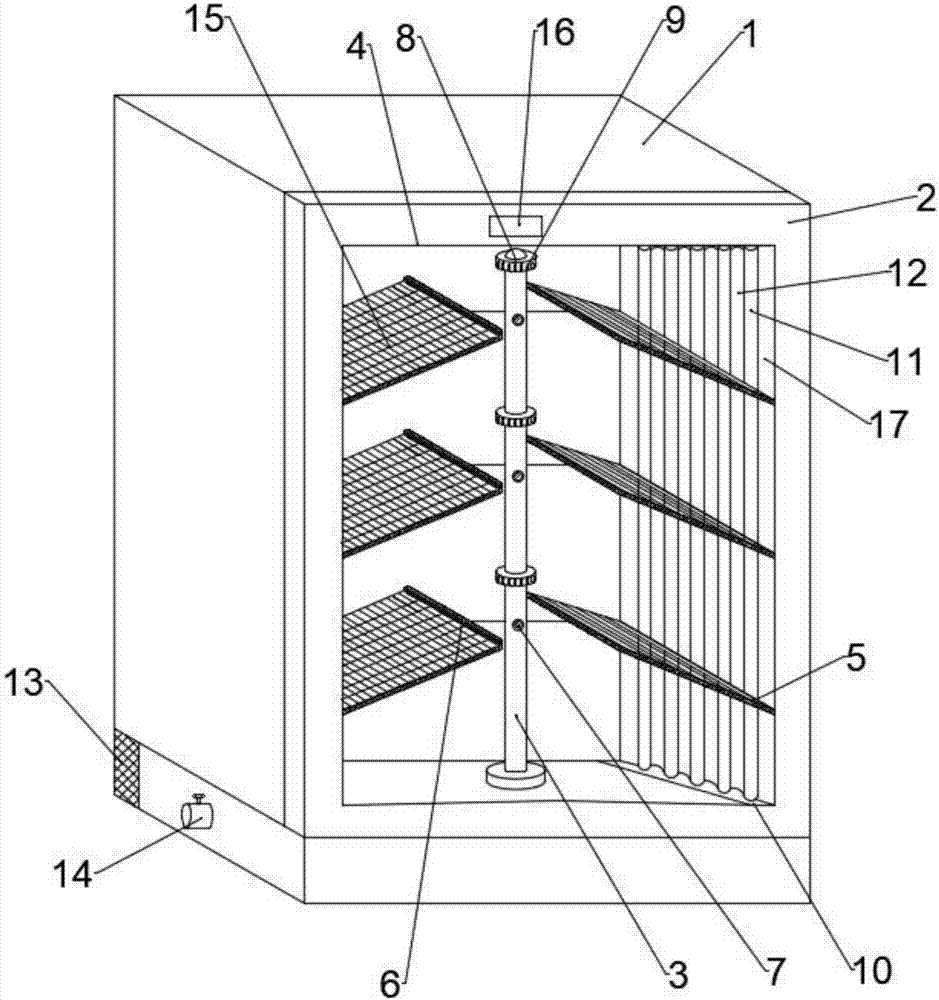

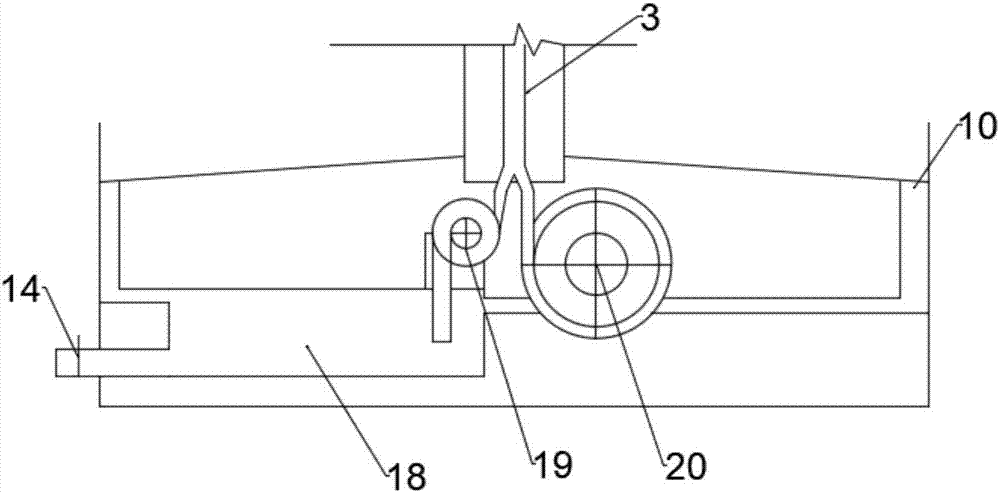

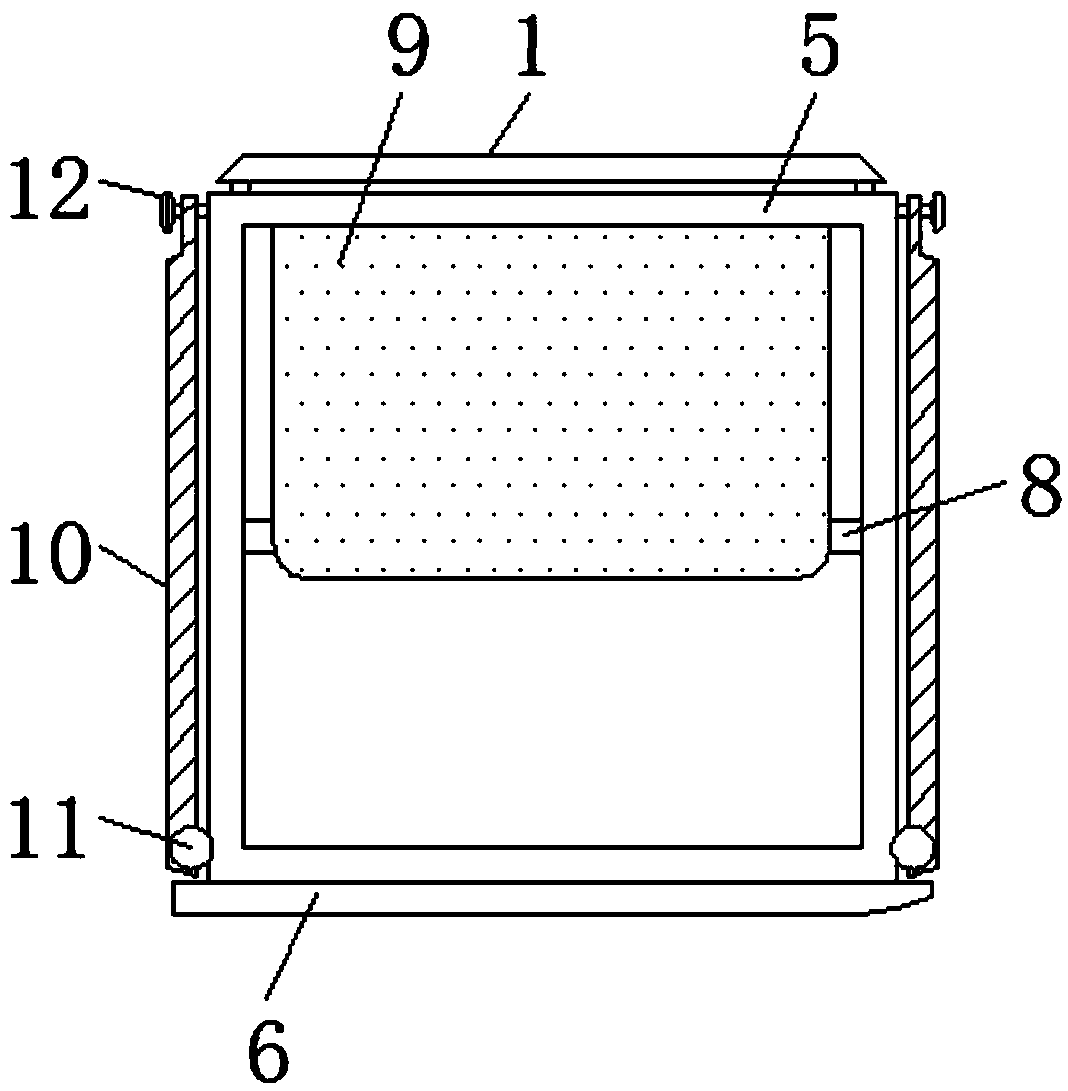

Germination accelerating device for watermelon seeds

InactiveCN107455043AIncrease germination areaPromote germinationGerminating apparatusEngineeringMoisture sensor

The invention discloses a germination accelerating device for watermelon seeds. The device comprises a box body and a box door, wherein the inner walls on two sides of the interior of the box body are provided with ceramic inner walls, the ceramic inner walls are lengthways provided with a plurality of strip-shaped electric heating plates, launders are arranged among the strip-shaped electric heating plates, the surfaces of the ceramic inner walls form a 45-degree angle with a horizontal plane and are provided with a plurality of groups of seed shelves, a mat net is interweaved between the rectangular seed shelves, the tops of the seed shelves are provided with sliding rails, an integration pipe is lengthways arranged at the bottom in the box body, the integration pipe is arranged between the seed shelves of two side walls of the box body, the integration pipe is provided with a plurality of swivel heads and temperature and humidity sensors, the side surfaces of the disc-shaped swivel heads are provided with spray orifices, the temperature and humidity sensors are arranged on the downsides of the swivel heads, a water tank is arranged at the bottom of the box body, the water tank is internally provided with a minitype water pump, the right end of the water tank is provided with a small-sized draught fan, and the minitype water pump and the small-sized draught fan are connected with the integration pipe through a pipeline.

Owner:颍上县田菊家庭农场

Special high-voltage cable for large electromechanical equipment

PendingCN114188083AGuaranteed cooling effectThermal real-time monitoring and assistanceInsulated cablesInsulated conductorsElectrical conductorCopper wire

The invention discloses a special high-voltage cable for large electromechanical equipment, which comprises a cable body, a conductor, an outer skin, an insulating layer and a filling layer, the cable body is composed of the outer skin and the conductor, the conductor comprises a copper wire core and the insulating layer wrapping the outer side, the outer side of the conductor is provided with a heat conduction strip which is distributed in a surrounding manner, and the heat conduction strip is arranged on the outer side of the cable body. The inner wall of the heat conduction strip is attached to the outer wall of the insulating layer, the pipe wall of the runner pipe is provided with a protruding part and a concave part, the concave part is of an elastic structure, and the elastic deformation of the concave part enables the runner pipe to be bent along with the cable body without being bent. According to the special high-voltage cable for the large electromechanical equipment, an internal fluid passing structure of the cable is redesigned, so that on the basis of effectively ensuring the heat dissipation effect, the passing structure can be correspondingly bent but not bent to be matched with necessary bending of the cable body during laying; and meanwhile, real-time monitoring and auxiliary heat dissipation can be carried out on heat generated by the conductor by utilizing a corresponding heat conduction mechanism.

Owner:王若琦

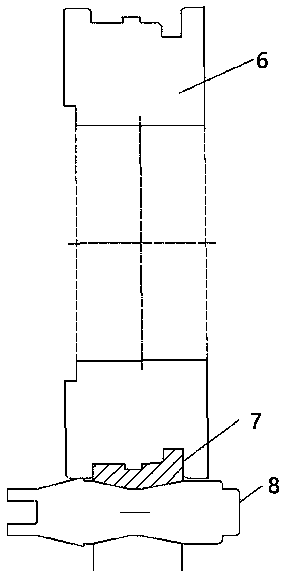

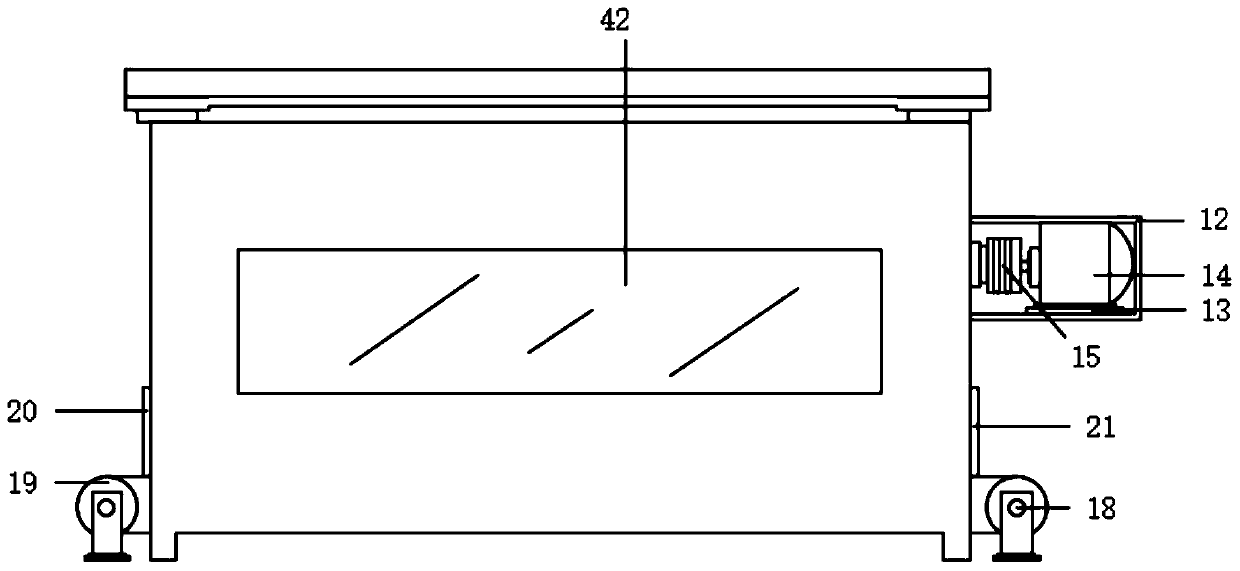

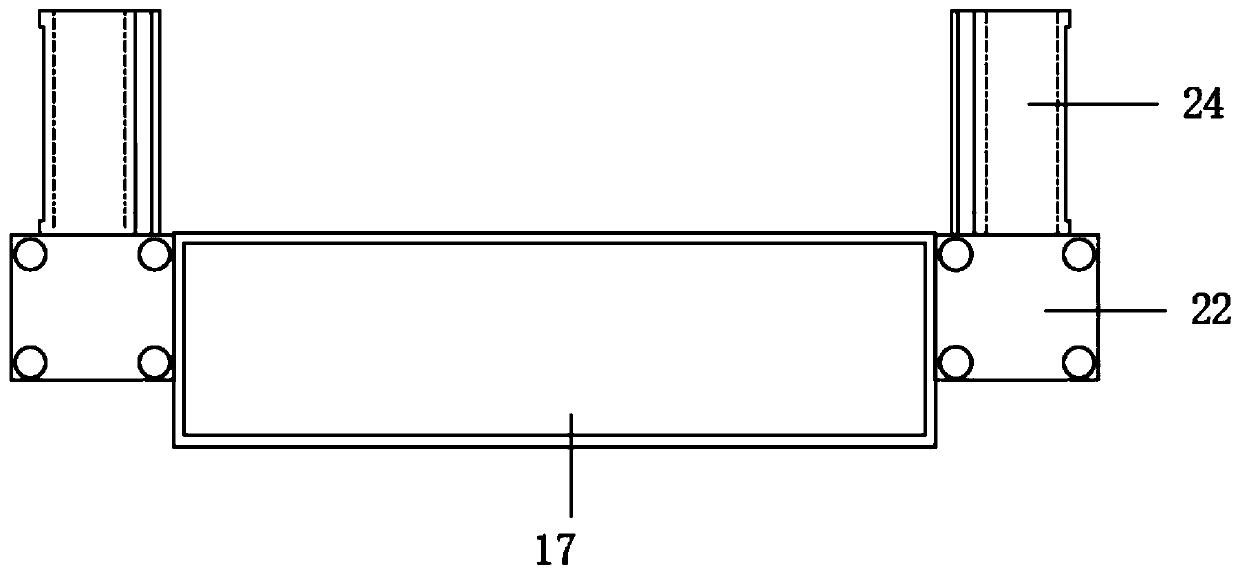

Dry-type roll iron core transformer

InactiveCN112397274AQuick repairGood for maintenance applicationsTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTransformerStructural engineering

The invention discloses a dry-type roll iron core transformer, relates to the technical field of transformers, and solves the problems that the bottom of a currently used transformer is of a fixed structure, does not have a quick extending structure and cannot quickly draw out and check a transformer core assembly. The dry-type roll iron core transformer comprises a base, ventilation frames are integrally arranged at the tops of the two sides of the base; two sets of side plates are fixedly arranged at the top of the base, rotating plates are fixedly arranged at the tops and sides of the rearsides of the two sets of side plates, vertical plates are fixedly arranged on the front sides of the two sets of side plates, a sliding function is provided for the transformer by arranging a slidingframe, and a transformer set can quickly slide on the inner side of the sliding frame in cooperation with sliding wheels. A fixing device can be used for quick fixing, when maintenance is needed, thefixing device can be opened to quickly pull out the transformer set towards the front side, the transformer is quickly overhauled, the operation is convenient, and the maintenance and application of the transformer are facilitated.

Owner:芜湖腾飞信息科技有限公司

Combined reactor and method of preparing pyrazolyl benzaldehyde acetal p-phenylene diamine bis-schiff base by using combined reactor

ActiveCN106966981AUniform and stable reactionImprove reaction efficiencyOrganic chemistryTransportation and packagingTemperature controlBenzaldehyde

The invention relates to a combined reactor and a method of preparing pyrazolyl benzaldehyde acetal p-phenylene diamine bis-schiff base by using the combined reactor. The reactor mainly comprises a heating magnetic stirrer and a mating reaction device, wherein the heating magnetic stirrer is provided with a vacuum chamber and can conduct accurate temperature control. The reactor can conduct the accurate temperature control and overcome the problems of local over excitation reaction, insufficient reaction, liquid splash and the like in the traditional schiff base synthesis process. At the same time, the invention discloses the method of preparing pyrazolyl benzaldehyde acetal p-phenylene diamine bis-schiff base by using the reactor. Prepared bis-schiff base has a greater conjugated pi structure; the reaction efficiency is improved; and the reaction time is saved.

Owner:陈宗源

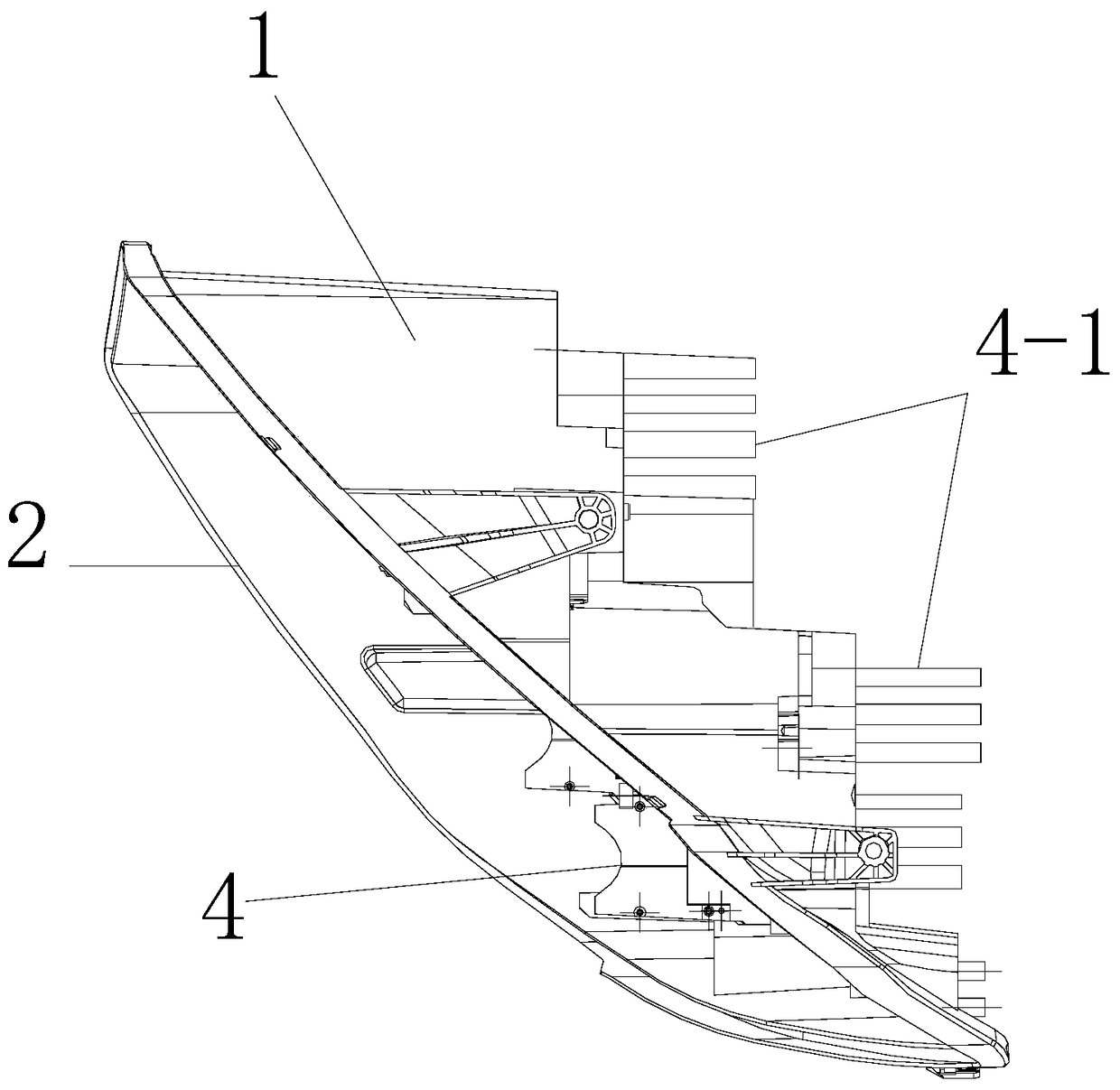

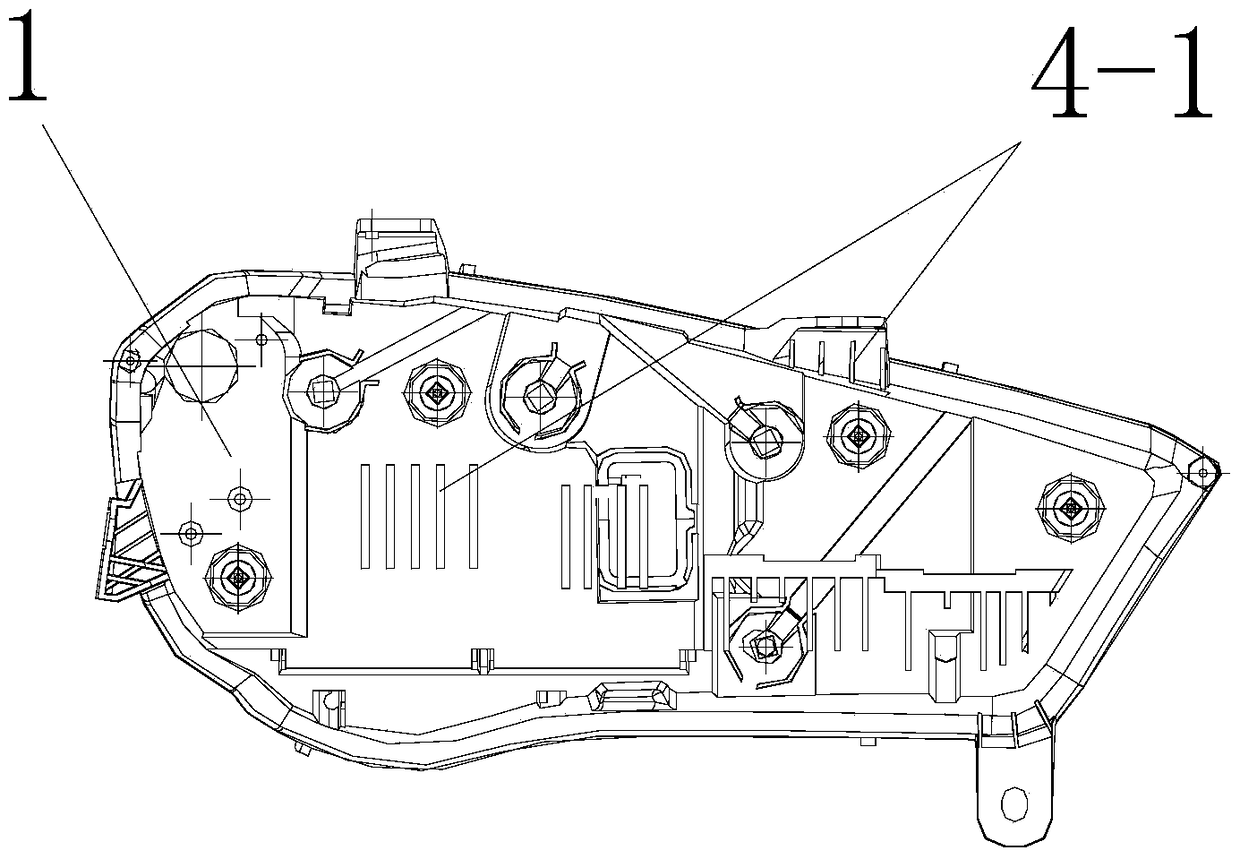

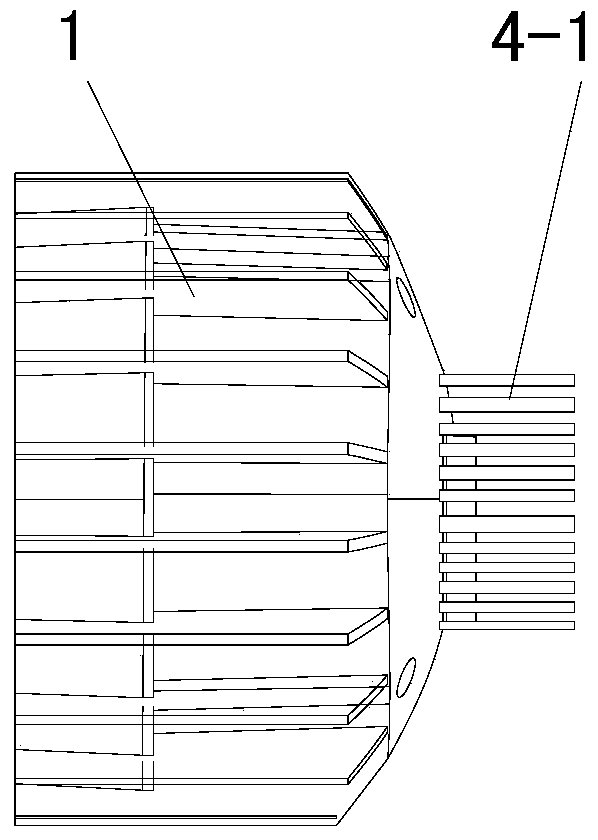

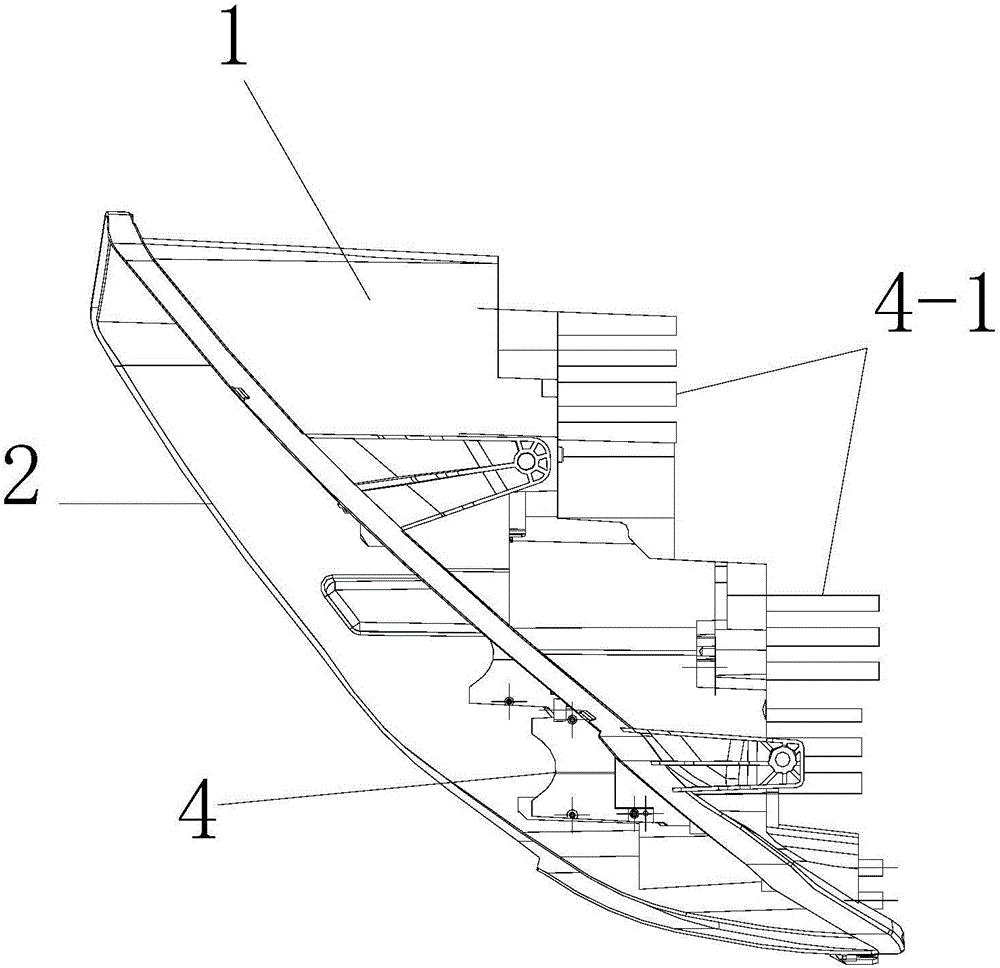

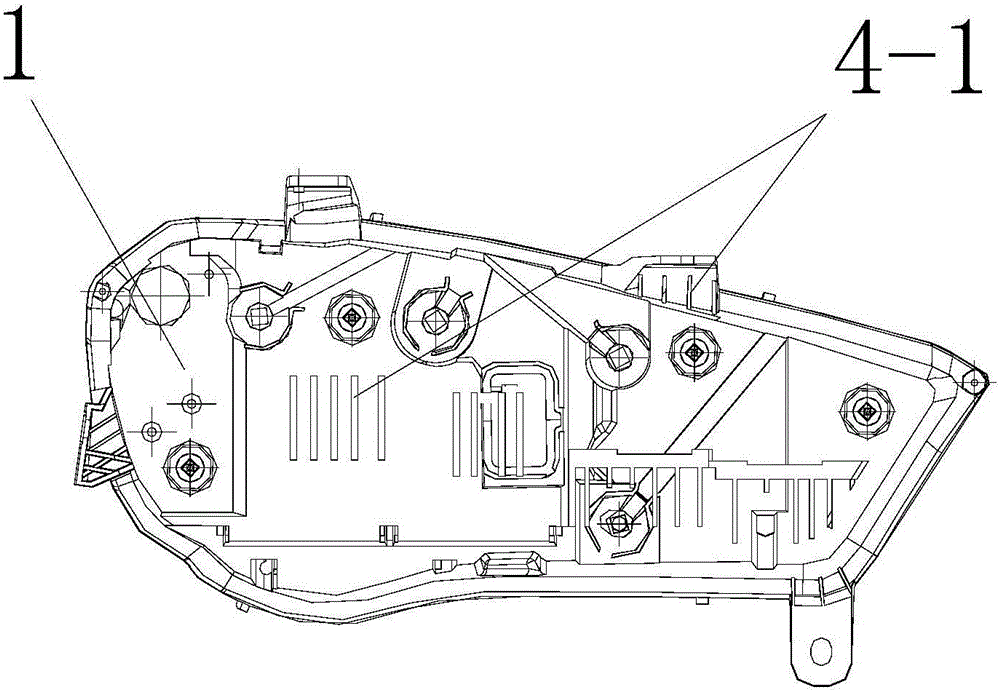

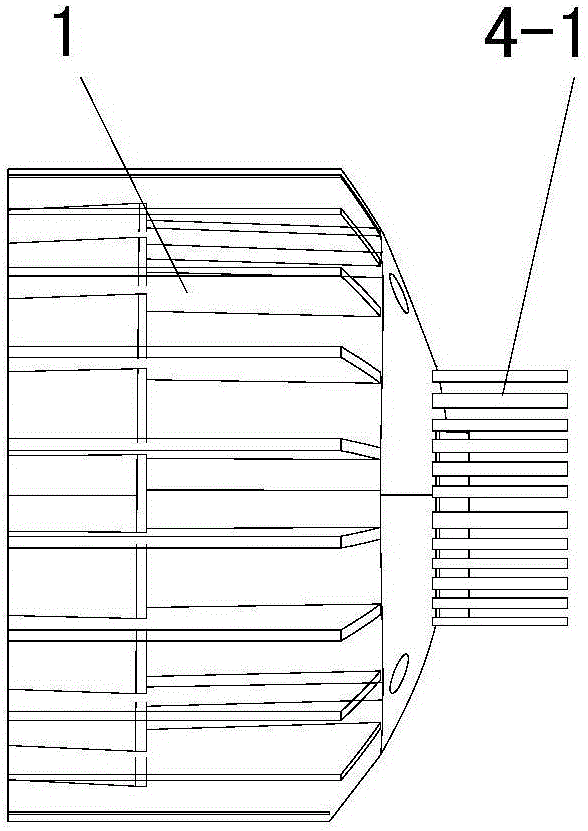

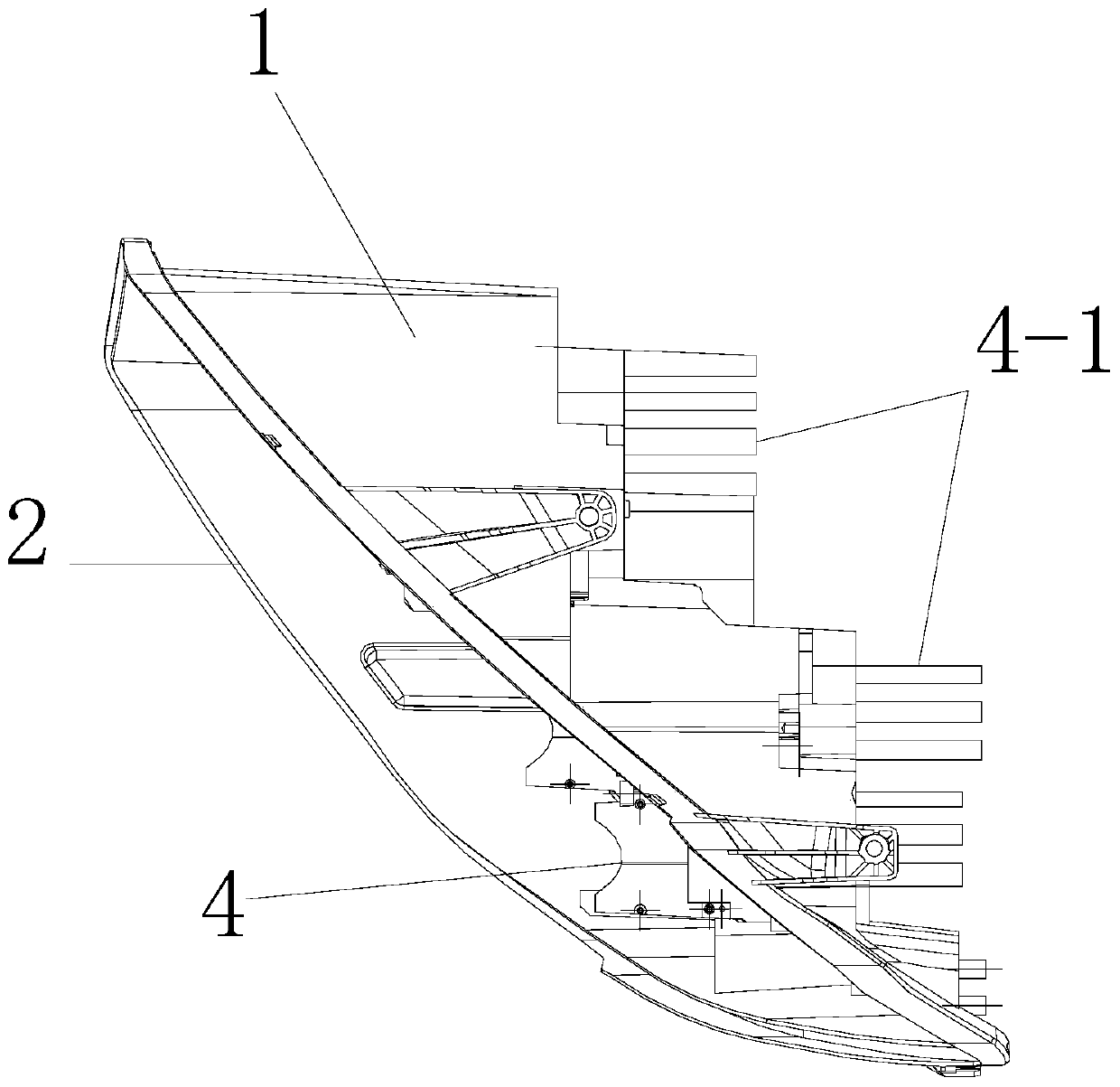

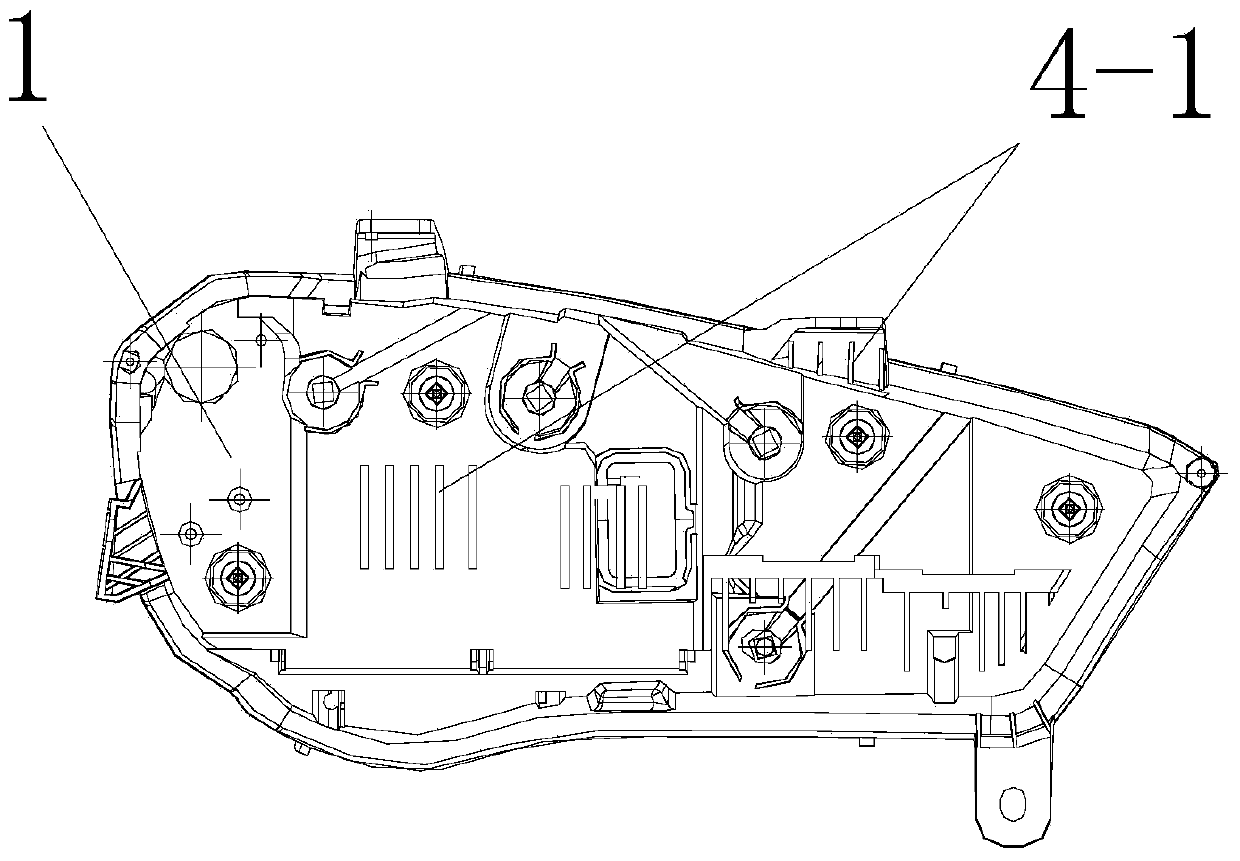

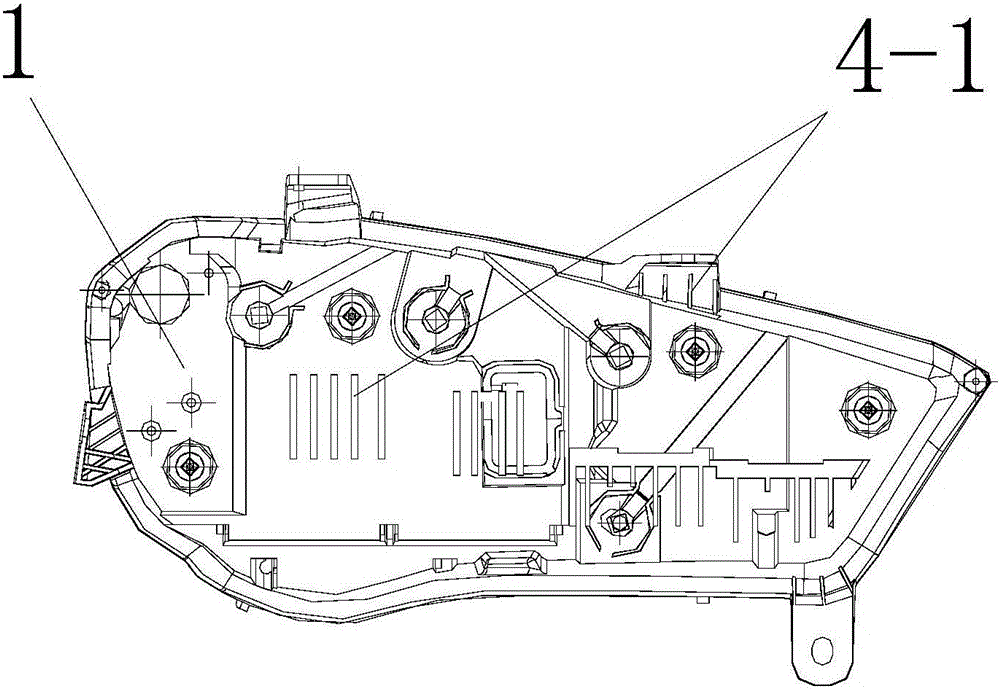

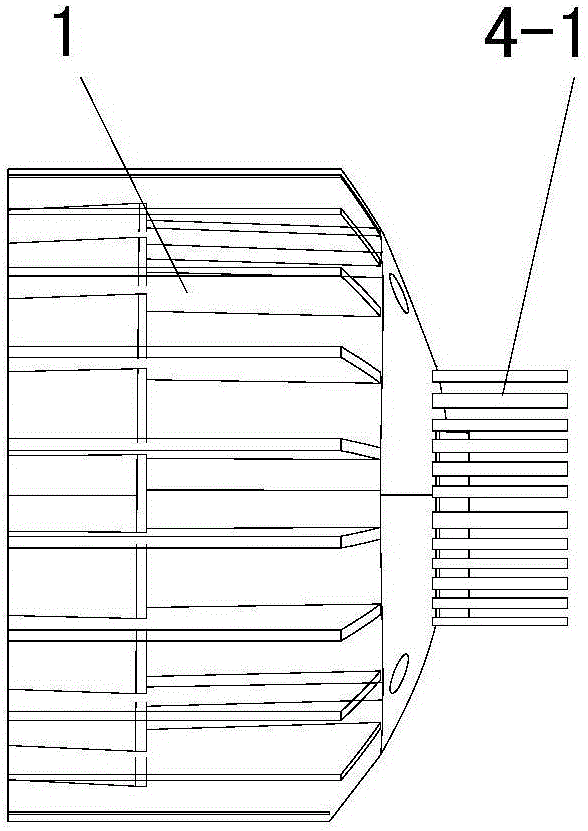

A kind of led headlight for car which can be forced air cooling when the car is in motion

ActiveCN105570785BGuaranteed tightnessImprove cooling effectVehicle headlampsLighting heating/cooling arrangementsEngineeringHeadlamp

Owner:CHANGZHOU TONGBAO PHOTOELECTRIC MFG CO LTD

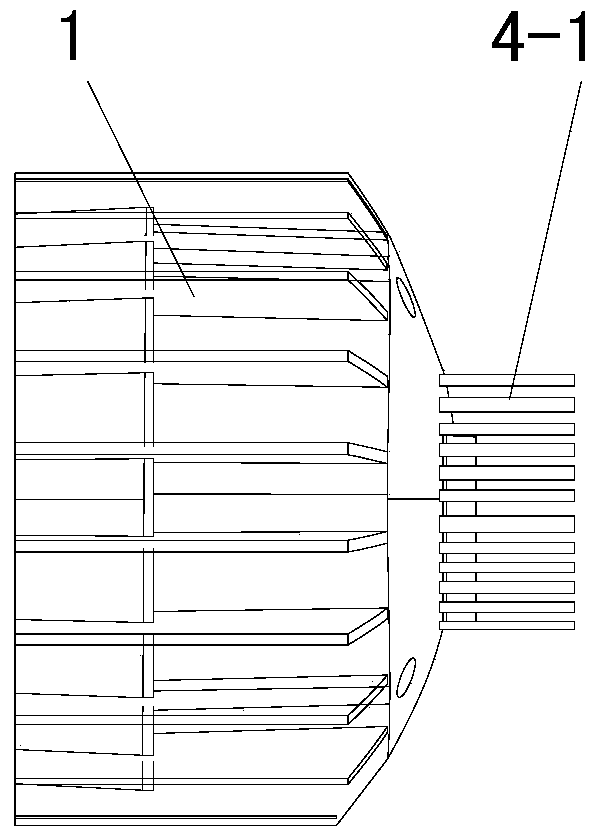

Automotive LED headlamp capable of achieving overall and rapid radiating and radiating method

ActiveCN105570784AImprove cooling effectRapid air coolingPoint-like light sourceLighting heating/cooling arrangementsEngineeringAirflow

The invention relates to an automotive LED headlamp capable of achieving overall and rapid radiating. The automotive LED headlamp comprises a thermal conductive plastic shell and a metal radiating support, the metal radiating support extends out of the shell and forms radiating fins, and the metal radiating support and the shell are in sealing fit. The part, extending out of the shell, of the metal radiating support is multiple radiating fins alternately distributed in parallel so that heat in the automobile headlamp can be rapidly output to the exterior of the shell of the automobile headlamp through the radiating fins, and airflow generated in the automotive travelling process can conduct radiating on the radiating fins extending out of the shell. In addition, the heat on the metal radiating support is transmitted to the shell through a combination part of the metal radiating support and the shell, and heat is radiated overall and rapidly through the shell; and meanwhile, in the automobile travelling process, the generated airflow conducts rapid air cooling on the overall shell.

Owner:CHANGZHOU TONGBAO PHOTOELECTRIC MFG CO LTD

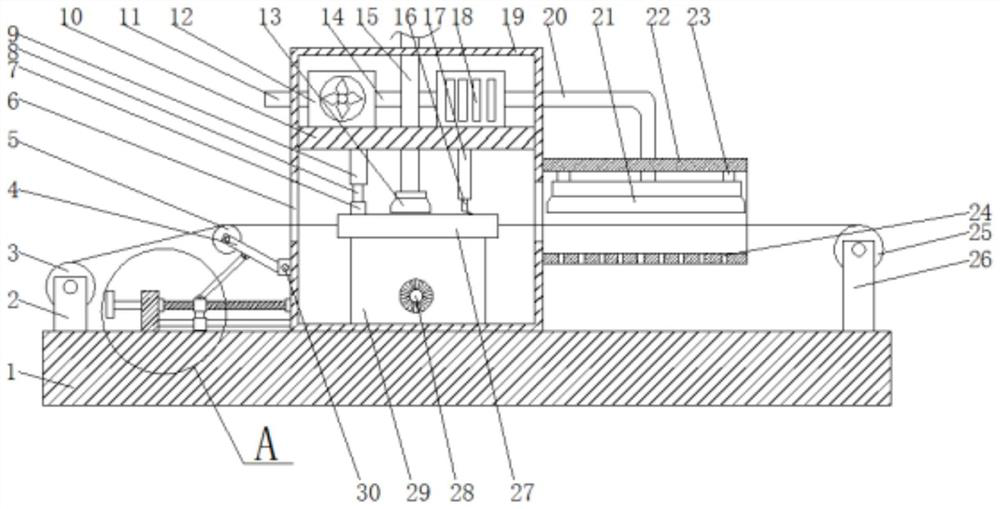

Environment-friendly powder coating extrusion equipment

PendingCN112606356AQuality assuranceTo achieve the effect of synchronous controlEngineeringMechanical engineering

The invention discloses environment-friendly powder coating extrusion equipment. The environment-friendly powder coating extrusion equipment comprises a charging barrel internally provided with a screw rod and a driving mechanism used for providing power for the screw rod, a heater is arranged on the outer side of the charging barrel, the charging barrel is vertically arranged below the driving mechanism, and a feeding port is formed in the upper portion of the charging barrel; a feeding device is arranged on one side of the upper part of the charging barrel and is connected with the feeding port through a feeding pipe; the feeding device comprises a stirring barrel and a stirring shaft, and the front end of the stirring shaft is arranged in the stirring barrel; stirring blades are annularly arranged at the front end of the stirring shaft, a material filtering plate is arranged at the position, below the stirring blades, of the stirring barrel, and filtering holes are evenly distributed in the material filtering plate at intervals; dehumidifying adsorption particles are arranged in the position, above the material filtering plate, of the stirring barrel, and the portion, below the material filtering plate, of the stirring barrel communicates with the feeding pipe; and an extrusion disc is arranged at an outlet in the bottom of the charging barrel, and a scraping device is arranged on the extrusion disc. According to the extrusion equipment, efficient dehumidification of powder coating extrusion processing materials can be achieved, and meanwhile the effect of rapid extrusion cooling is achieved in cooperation with a scraping mechanism.

Owner:HUNAN LIANXIN SCI & TECH CO LTD

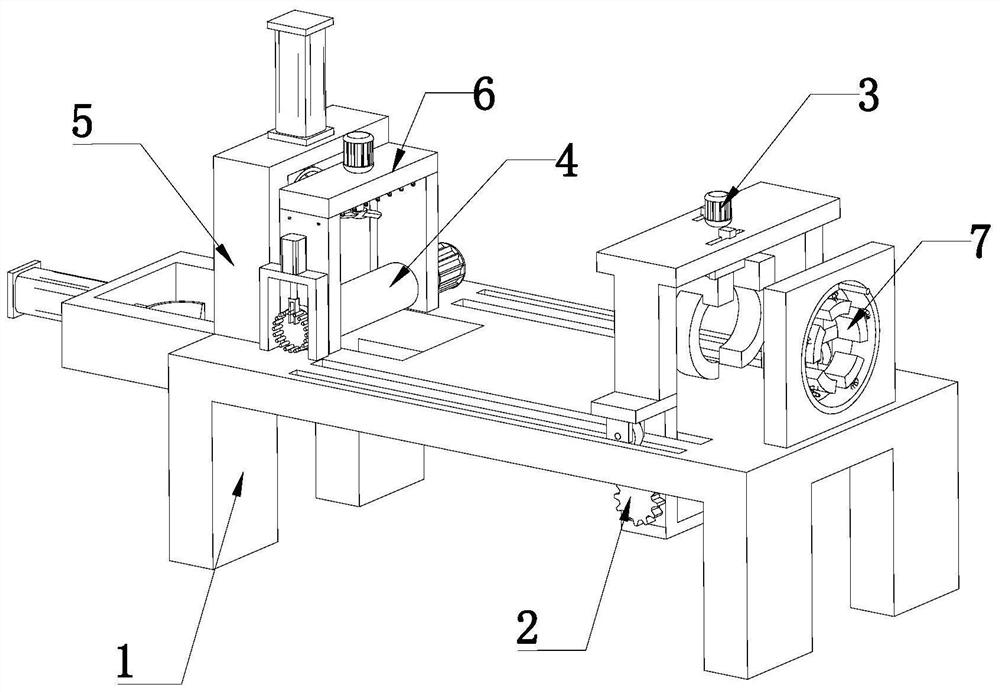

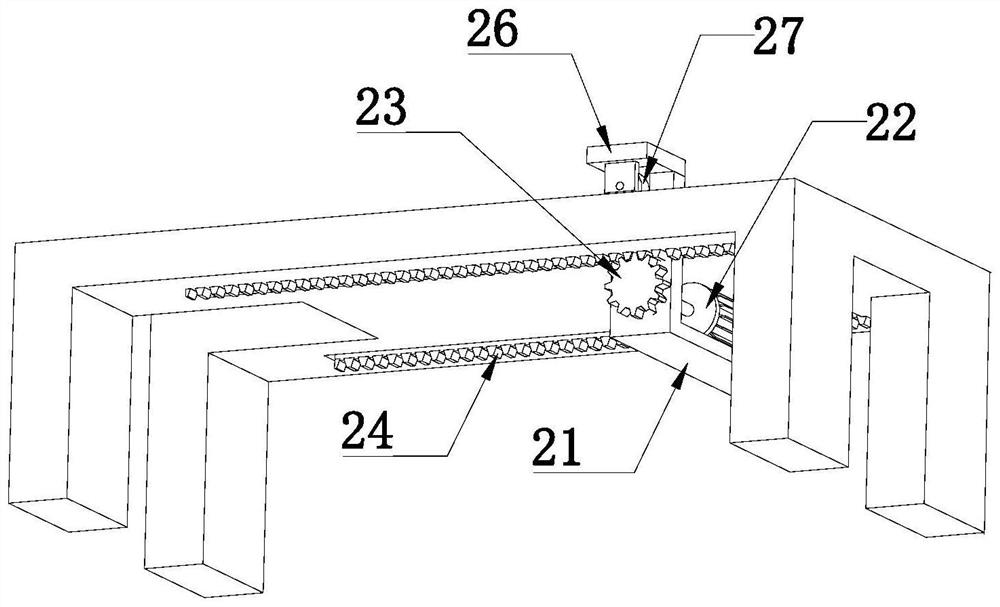

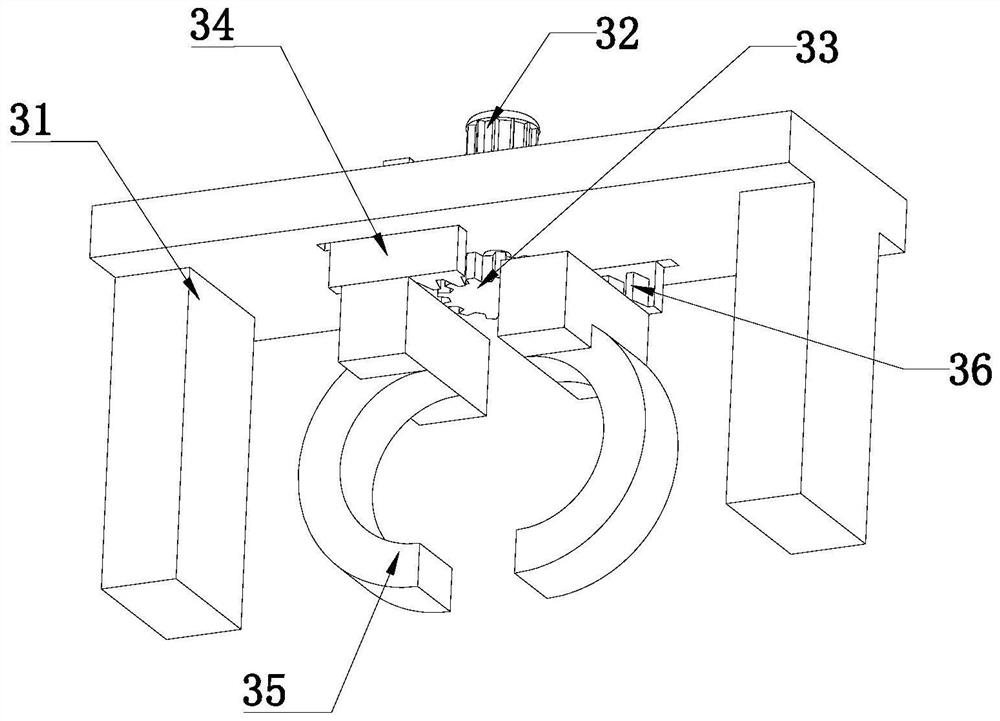

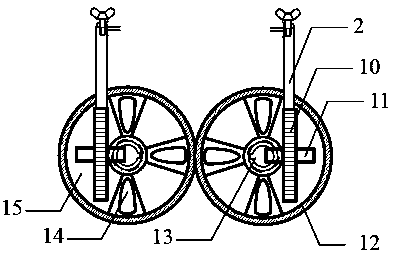

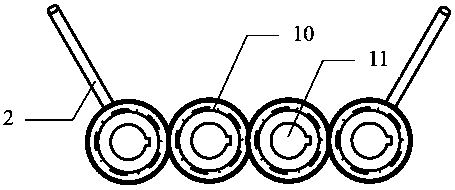

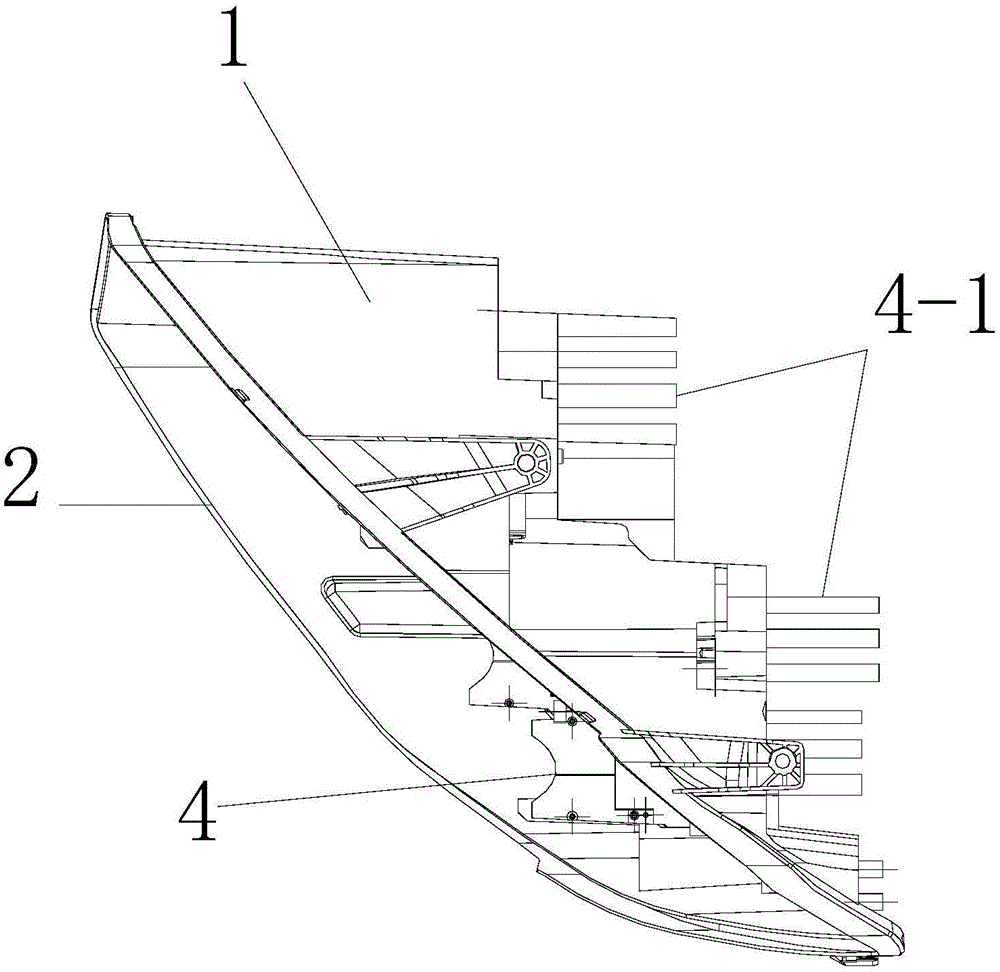

Hydraulic pipe bending machine

ActiveCN113751559AAdjust the bend angleAvoid offsetMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses a hydraulic pipe bending machine, and belongs to the technical field of pipe bending equipment. The hydraulic pipe bending machine comprises a workbench, a conveying assembly, a fixing assembly, an adjusting assembly and a bending assembly, the conveying assembly is arranged on the workbench, the conveying assembly is in sliding fit with the workbench, the fixing assembly is arranged on the conveying assembly, the adjusting assembly is arranged on the workbench, and the bending assembly is arranged beside the adjusting assembly. According to the hydraulic pipe bending machine, one end of a pipe is clamped and fixed through the fixing assembly, the conveying assembly works to drive the fixing assembly and the pipe to move forwards, the part, needing to be bent, of the pipe is moved to the position above the adjusting assembly, the adjusting assembly adjusts the bending angle of the pipe, the bending assembly works to bend the pipe, and the bending angle of the pipe is adjusted according to equipment applied to the pipe.

Owner:广东科欣电气有限公司

Heat conducting-radiating automobile headlamp made of novel energy material

PendingCN107575828AEfficient deliveryRapid air coolingVehicle headlampsLighting heating/cooling arrangementsHeat conductingEngineering

The invention discloses a heat conducting-radiating automobile headlamp made of a novel energy material, which comprises a radiator. A liquid metal fixing seat is arranged in the radiator in a penetrating manner, one end of the liquid metal fixing seat is provided with a flat liquid metal bar, the flat liquid metal bar is filled with liquid metal having a heat conducting action, an LED lamp panelis mounted on the surface of the flat liquid metal bar, and the LED lamp panel is provided with an LED light source. The lamp base part, i.e., the front end heat conducting part adopts the novel material, and the novel material is the liquid metal or other materials better than aluminum and copper in heat conduction, such that heat on the LED lamp panel can be more efficiently transferred to the radiator on the back side, the radiator adopts a multi-fin design to increase a radiating area furthest, a fan is mounted on the back end of the radiator, fins of the radiator can be air-cooled rapidly, and the purpose of efficient heat dissipation is realized.

Owner:广东前品科技有限公司

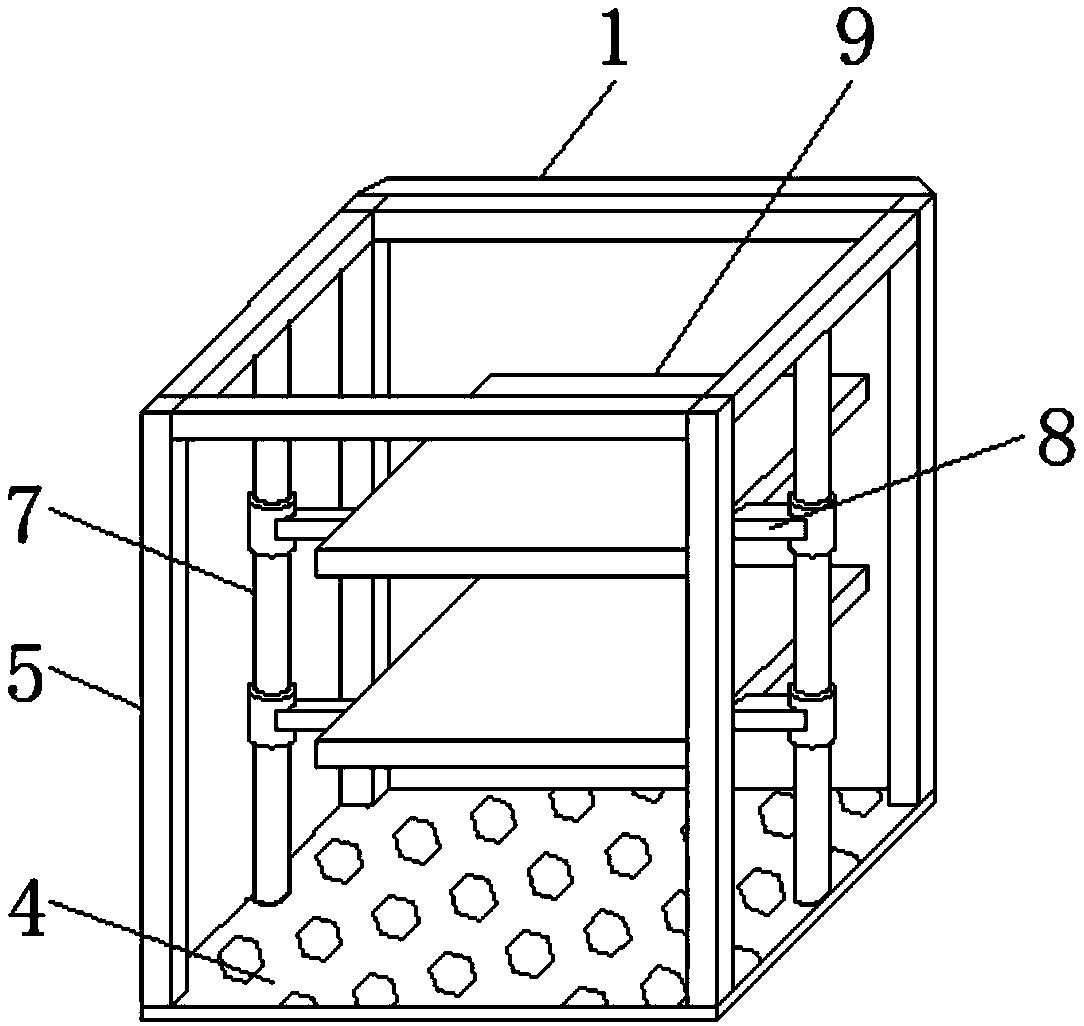

Resonance elimination compensation cabinet convenient to overhaul and dissipate heat

PendingCN108110659AGood dustproof performanceReasonable designSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineering managementResonance

The invention discloses a resonance elimination compensation cabinet convenient to overhaul and dissipate heat. The cabinet comprises a cabinet body, a cabinet body frame, a component plate an a sideplate, wherein a pedestal box is arranged at the bottom end of the cabinet body, the cabinet body frame is installed on a pedestal plate, a cabinet door is installed on the cabinet body frame, and thecabinet body frame is mutually connected with the pedestal plate via a vertical rod, the component plate is mutually connected with the vertical rod via a connection plate, one side of the componentplate is installed on the inner wall of the cabinet body, one side of the side plate is mutually connected with the cabinet body frame via a hinge, the other side of the side plate is mutually connected with the cabinet body frame via a fixing piece, the side plate is provided with an exhaust outlet, a dust screen is arranged on the inner side of the exhaust outlet, and an observation window is installed on the side plate. The resonance elimination compensation cabinet convenient to overhaul and dissipate heat can rapidly dissipate heat of circuit elements in the compensation cabinet, is better in dust prevention performance, and meanwhile is convenient to disassemble and assemble components in the cabinet boy, more reasonable in design, and very convenient to use.

Owner:江西力天机械有限公司

Tin plating device and tin plating method for light-condensing welding strip

PendingCN113862600AScientific and reasonable structureSafe to useMolten spray coatingMetallurgyTin plating

The invention discloses a tin plating device and a tin plating method for a light-condensing welding strip. A base and a tin plating box are included, the tin plating box is fixedly installed at the top of the base, openings are formed in the side walls of the two sides of the tin plating box, a first roller frame is arranged at one side of the top of the base, and a third roller frame is arranged at the other side of the top of the base; and a wire guide roller is movably installed at one side of the top of the base through the first roller frame, and a winding roller is movably installed at the other side of the top of the base through the third roller frame. By means of the tin plating device and the tin plating method, the structure is scientific and reasonable, use is safe and convenient, the tension degree of the welding strip is conveniently adjusted before tin plating, then the tin plating effect of the welding strip is improved, and spraying is comprehensive; the tin plating thickness actually required by the welding strip can be adjusted, so that the tin plating device and the tin plating method are suitable for production and processing of welding strips with different tin layer thicknesses; and the welding strip obtained after tin plating can be quickly cooled by air, so that the welding strip obtained after tin plating can be quickly wound, and the tin plating efficiency of the whole welding strip is high.

Owner:江阴市晨达新能源科技有限公司

An intelligent standard ice cube processing device

Owner:泰安岱创科技咨询有限公司

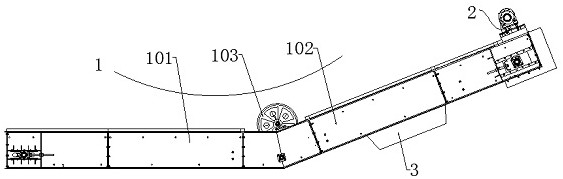

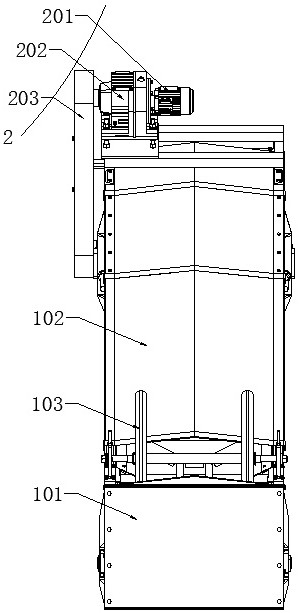

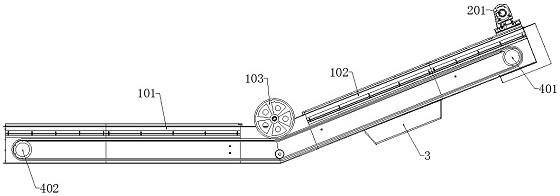

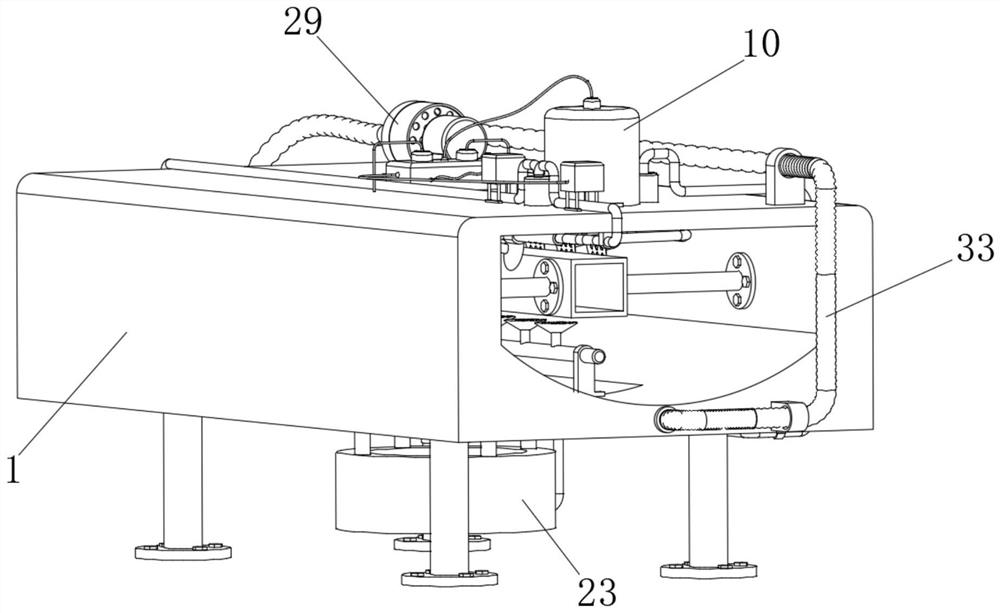

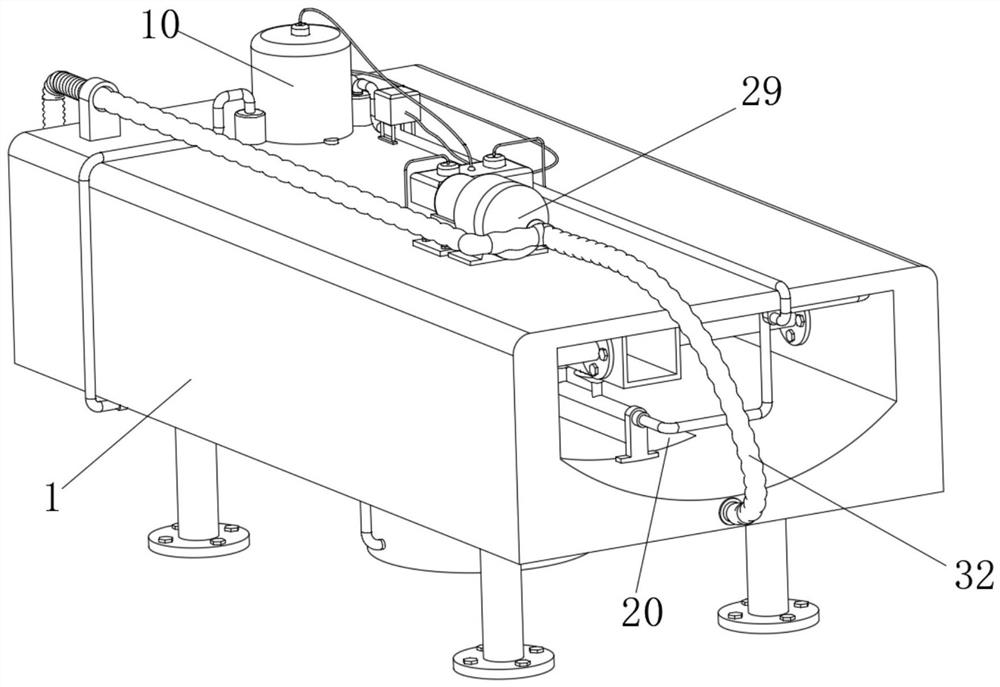

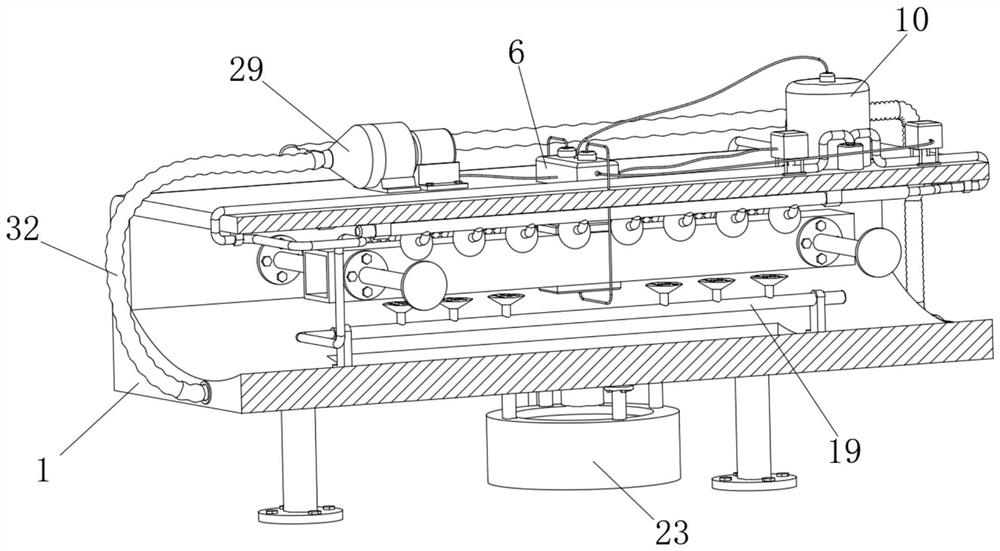

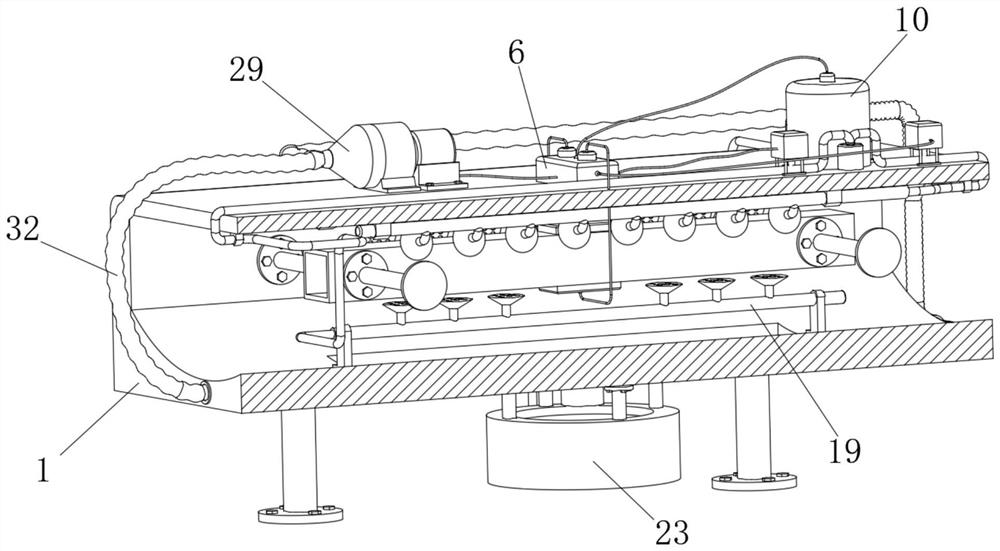

Transportation equipment for bio-organic fertilizer production with air-cooled anti-caking function

ActiveCN114212334BAvoid cakingAvoid enteringConveyorsClimate change adaptationAgricultural scienceAgricultural engineering

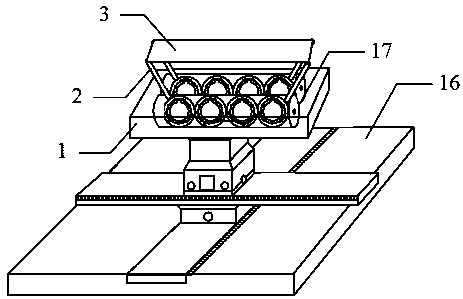

The invention discloses transportation equipment for bio-organic fertilizer production with air-cooling and anti-caking functions, which belongs to the field of transportation technology. The transportation equipment for bio-organic fertilizer production includes a transportation box and a power mechanism. At one end, a conveyor belt is installed inside the transport box, and the conveyor belt is connected to the power mechanism. The conveyor belt transports the bio-organic fertilizer particles, and performs air cooling and vibration on the particles during transportation to prevent the particles from agglomerating. While the particles are vibrating, the temperature of the particles is also cooled. The conveyor belt collects the raw material powder during the vibration process to prevent the raw material powder from entering the packaging process. The raw material powder is transferred, and the collected powder is transferred to the granulation process to improve the efficiency of producing granules and reduce the loss during the production process.

Owner:JIANGSU LIANGYOU AGRO MACHINERY

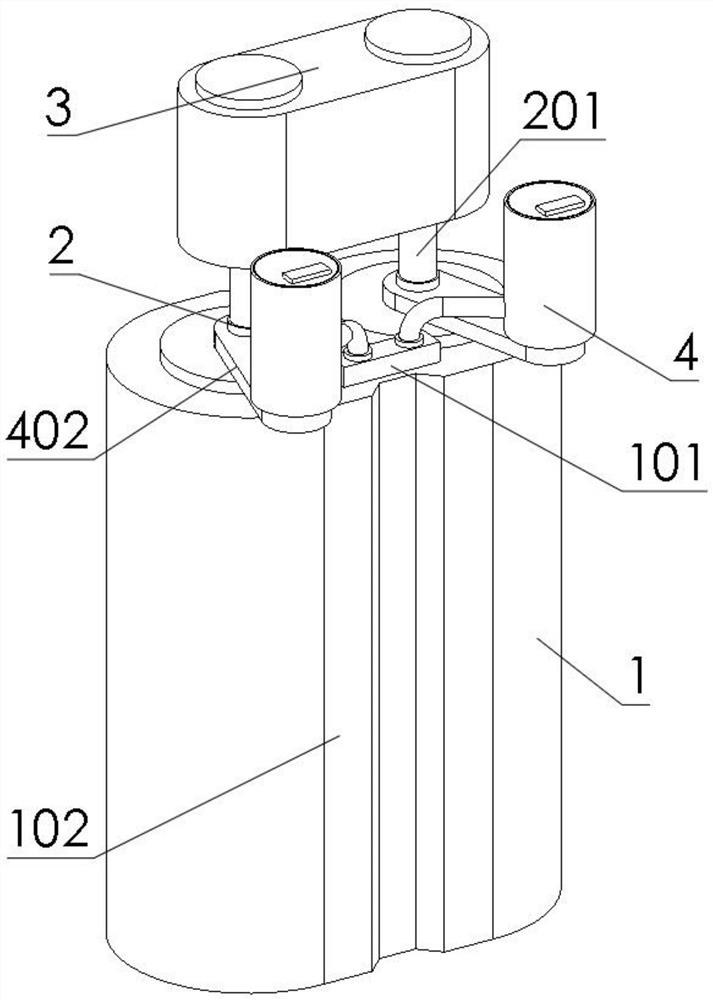

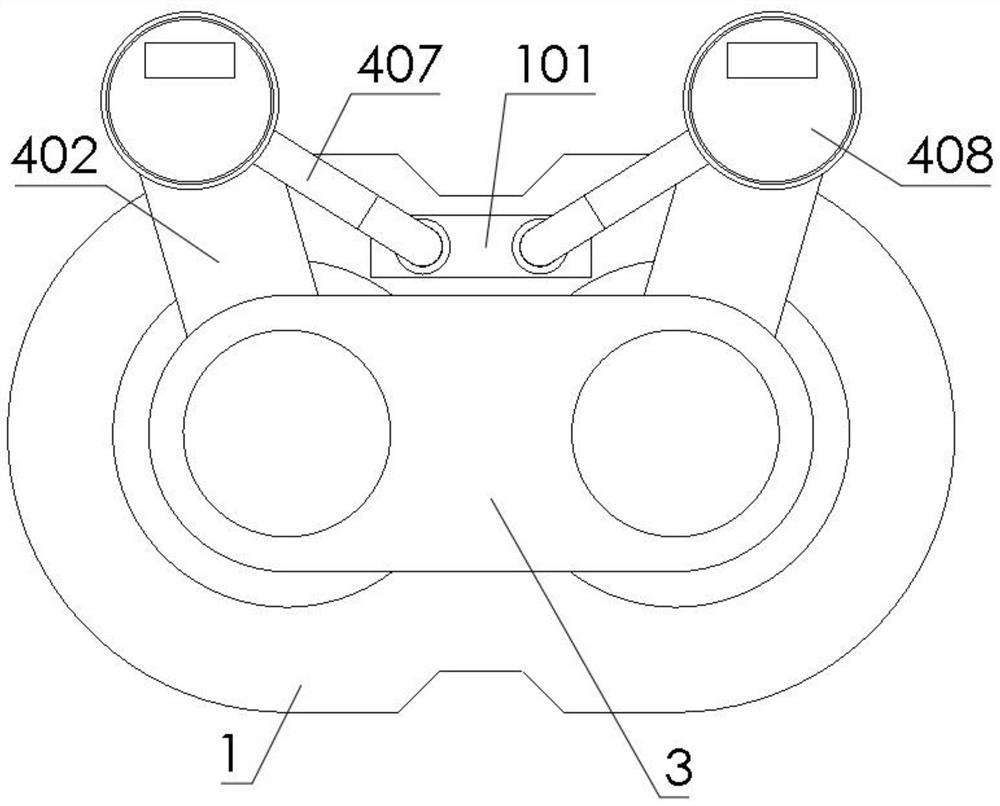

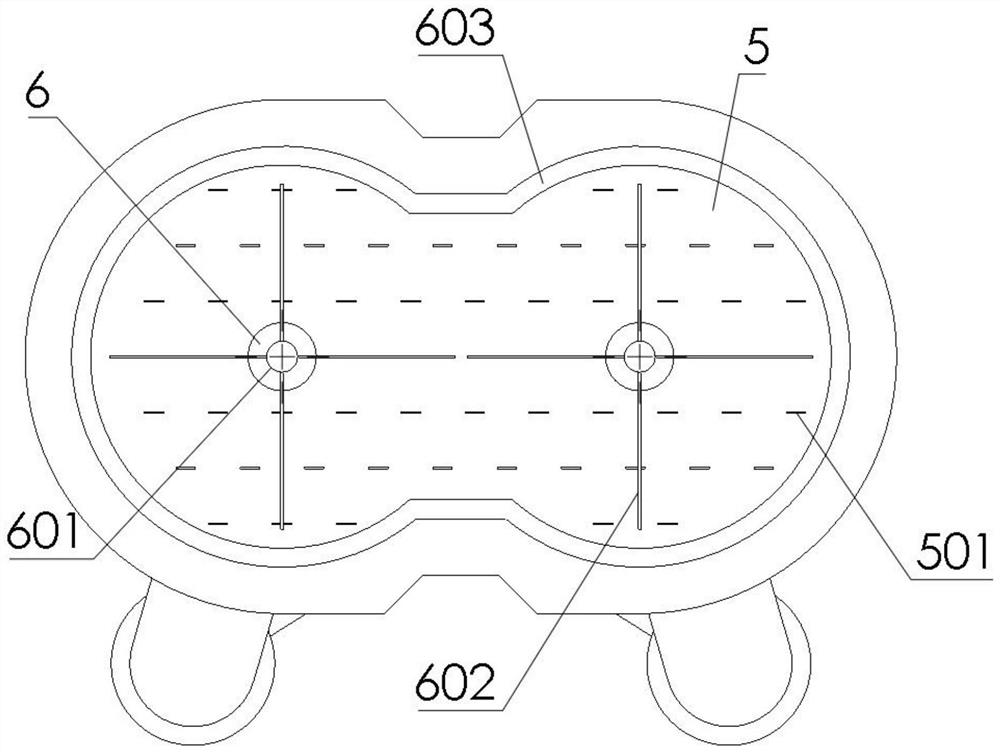

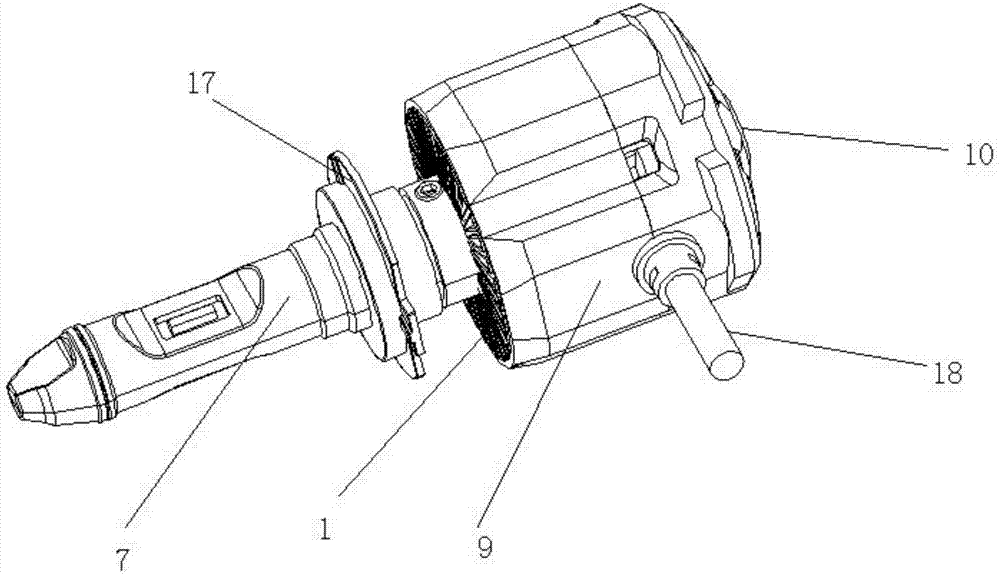

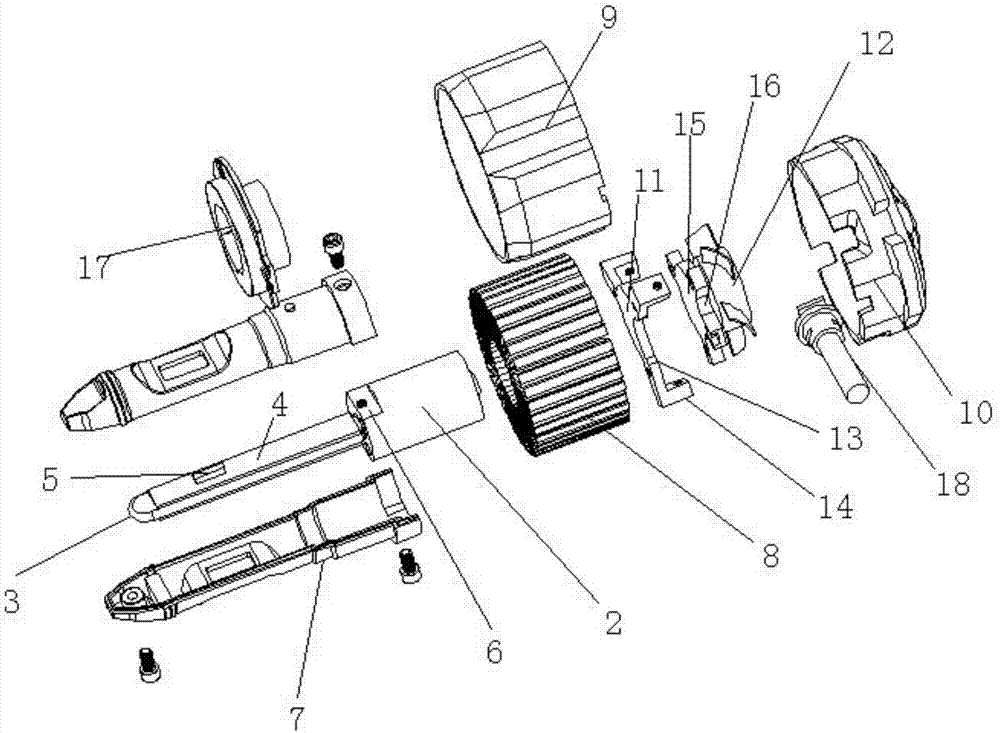

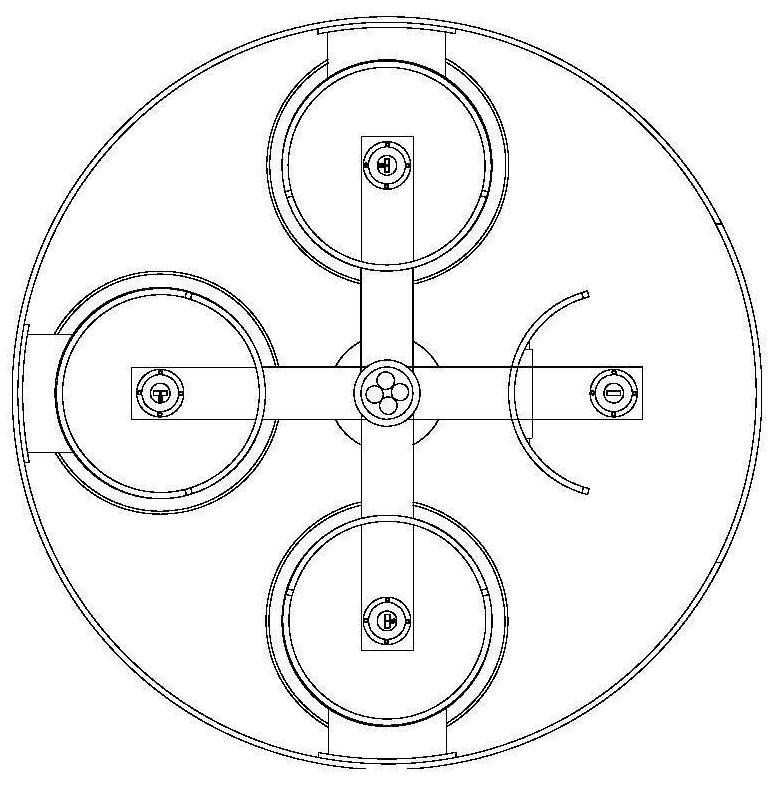

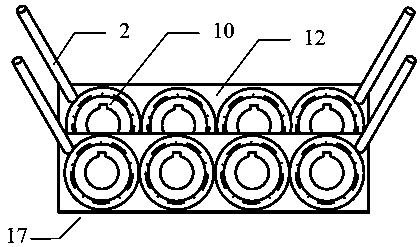

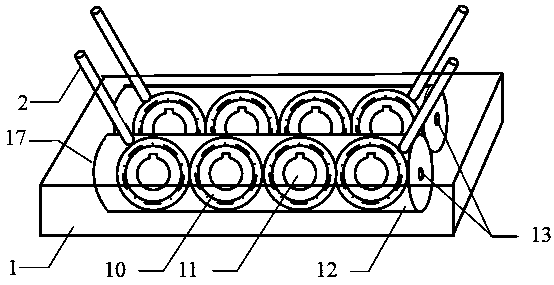

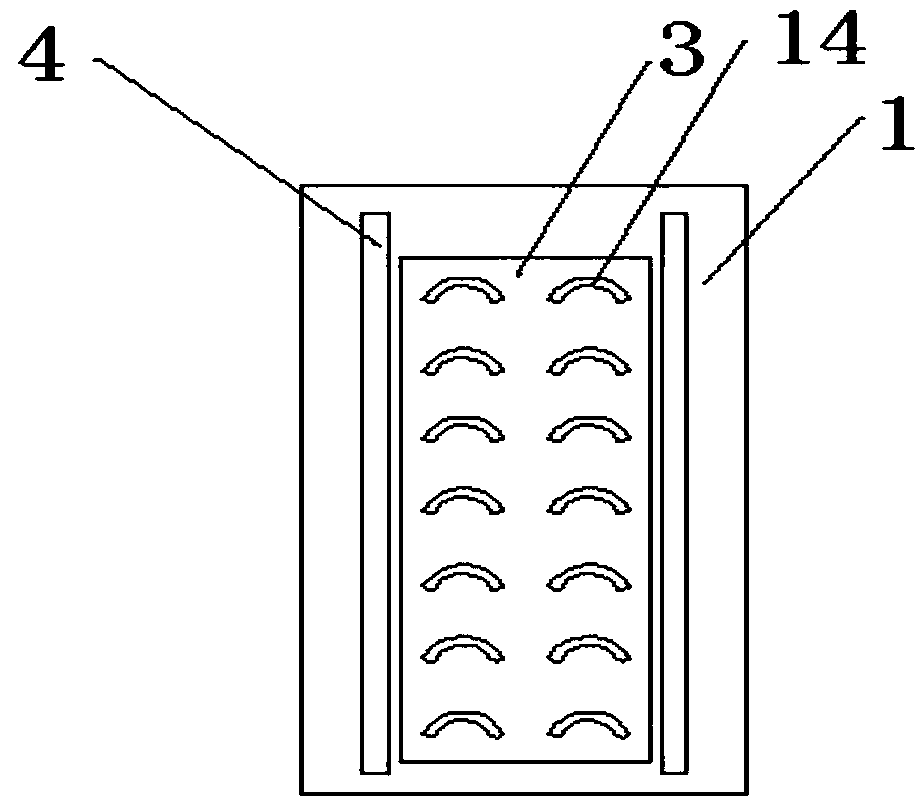

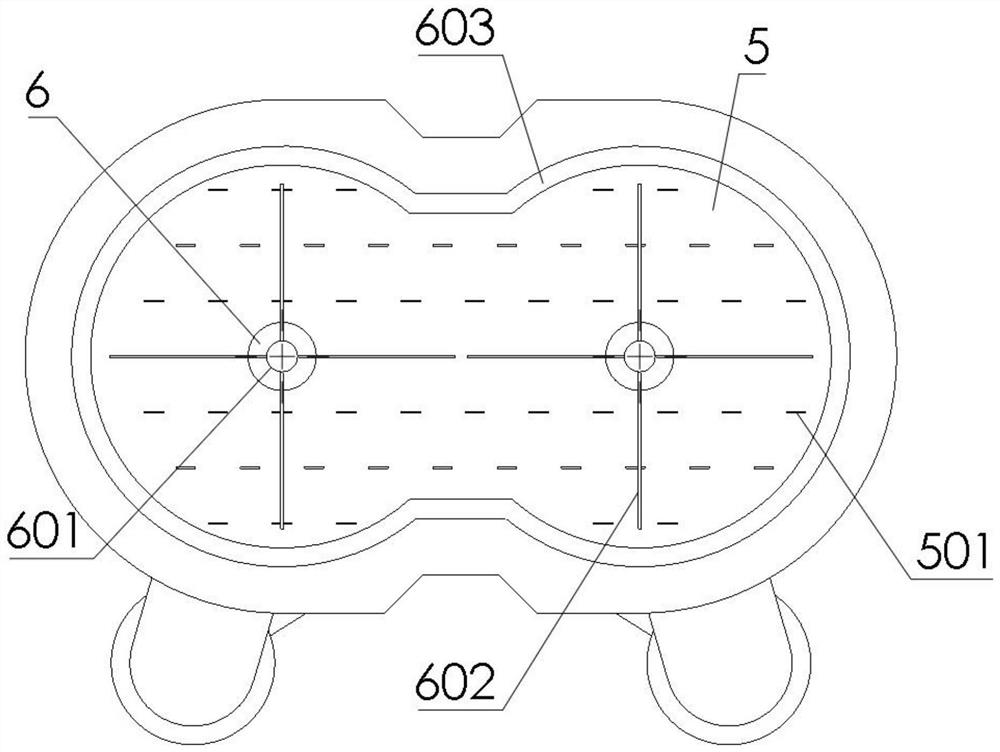

An overhead biochip carrier

The invention provides an overhead biological chip objective table. The overhead biological chip objective table is mainly composed of a base table and a rotating device for adjusting chip rack rods.The overhead biological chip objective table is characterized in that the base table is a cuboid, the interior of the base table is machined into a hollow box shape, and the rotating device for adjusting the chip rack rods is mounted in the base table. The position, at the top of the rotating device, in the base table is connected with the chip rack rods stretching out of the base table. The rotating device is composed of four or more four-direction balls, wherein the number of the four-direction balls is an even number; or the rotating device is composed of two or more columnar gears and fouror more small gears, wherein the number of the columnar gears and the number of the small gears are both even numbers. The overhead biological chip objective table has the advantages that the machining tasks that the height is adjusted coordinately, chips of different plane sizes are elevated and clamped, and the chips are carved in a hollowed-out manner can be completed; and the structure is simple, the machining cost is low, and machining and production are facilitated.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Overhead biological chip objective table

The invention provides an overhead biological chip objective table. The overhead biological chip objective table is mainly composed of a base table and a rotating device for adjusting chip rack rods.The overhead biological chip objective table is characterized in that the base table is a cuboid, the interior of the base table is machined into a hollow box shape, and the rotating device for adjusting the chip rack rods is mounted in the base table. The position, at the top of the rotating device, in the base table is connected with the chip rack rods stretching out of the base table. The rotating device is composed of four or more four-direction balls, wherein the number of the four-direction balls is an even number; or the rotating device is composed of two or more columnar gears and fouror more small gears, wherein the number of the columnar gears and the number of the small gears are both even numbers. The overhead biological chip objective table has the advantages that the machining tasks that the height is adjusted coordinately, chips of different plane sizes are elevated and clamped, and the chips are carved in a hollowed-out manner can be completed; and the structure is simple, the machining cost is low, and machining and production are facilitated.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Intelligent cooling device for aluminum profile forming

The invention relates to the technical field of aluminum profile forming and cooling devices, and discloses an intelligent cooling device for aluminum profile forming. Through arrangement of a cooling pump and the like, rapid cooling on a casting shaping pipe and the upper portion and the lower portion of a formed high-temperature aluminum profile in the casting shaping pipe is achieved, the cooling effect in unit time is improved, through arrangement of a temperature sensor, intelligent cooling is carried out according to the upper temperature and the lower temperature of the casting shaping pipe, constant cooling is avoided when the temperature is low, and therefore waste of resources such as cooling liquid is avoided, through the arrangement of a collecting groove, a collecting pipe and the like, the cooling liquid can be recycled in a centralized mode after being sprayed out of a multi-hole spray head, enters a collecting box below through the collecting pipe, and then is sucked into the cooling pump through a water inlet pipe, so that the cooling liquid is recycled, waste caused by lack of a recycling mechanism after high-pressure spraying of the cooling liquid is avoided, and through the arrangement of an air outlet pipe and the like, it is ensured that the cooling liquid is always kept at a low temperature before cooling, and cooling liquid collection is facilitated.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

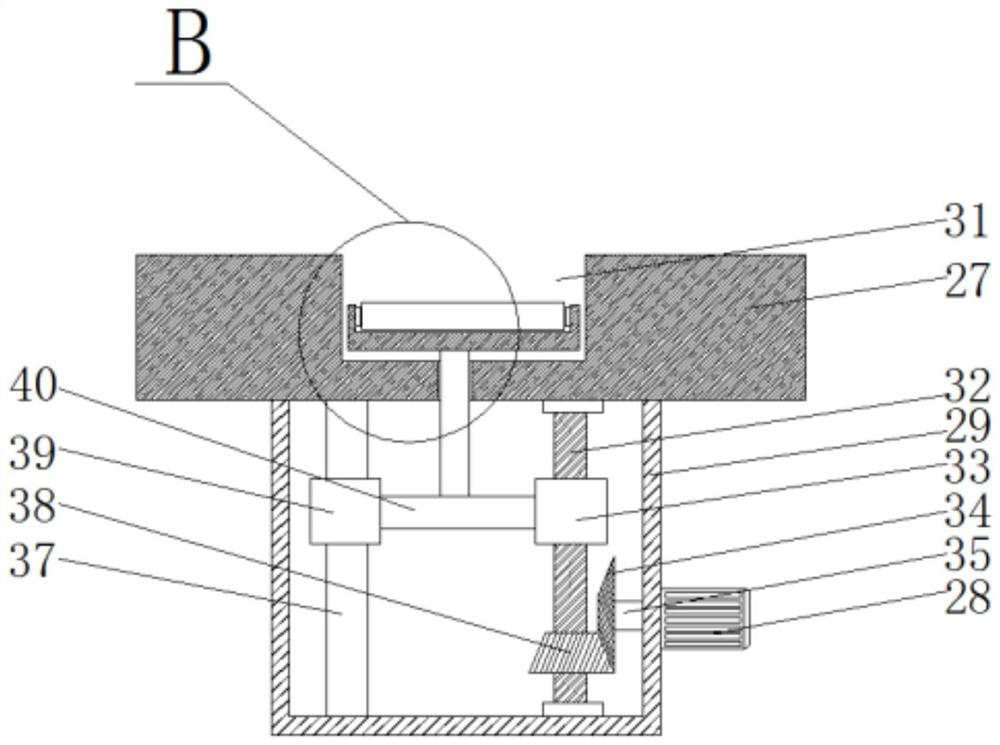

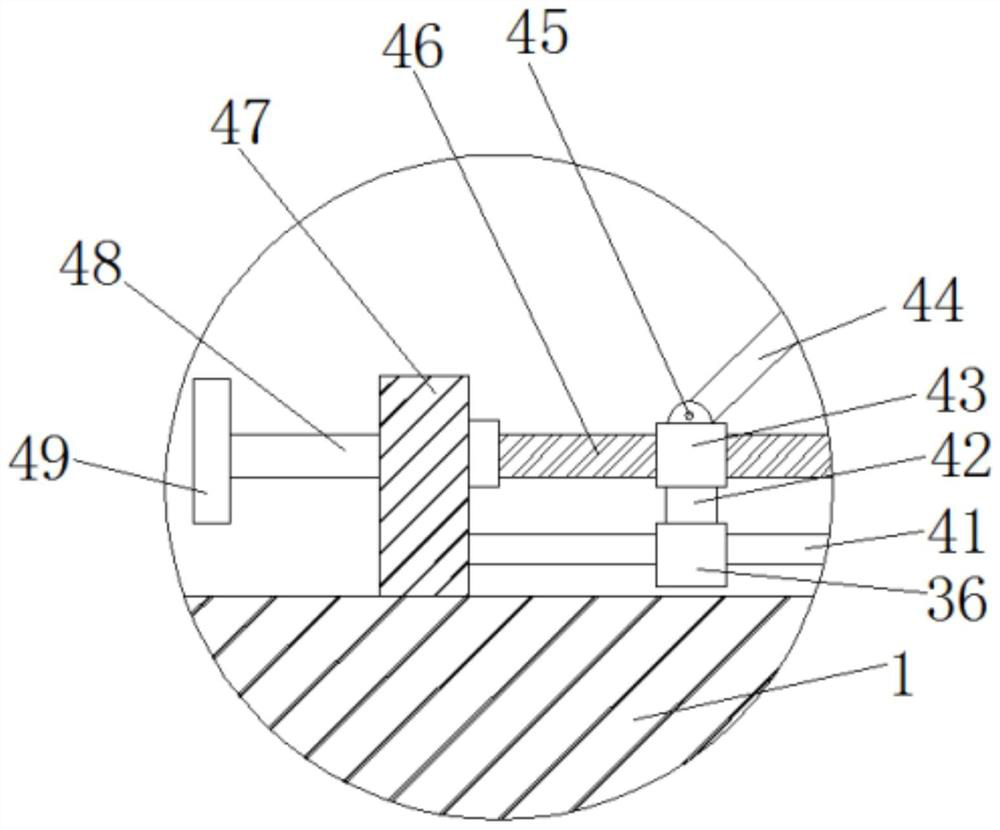

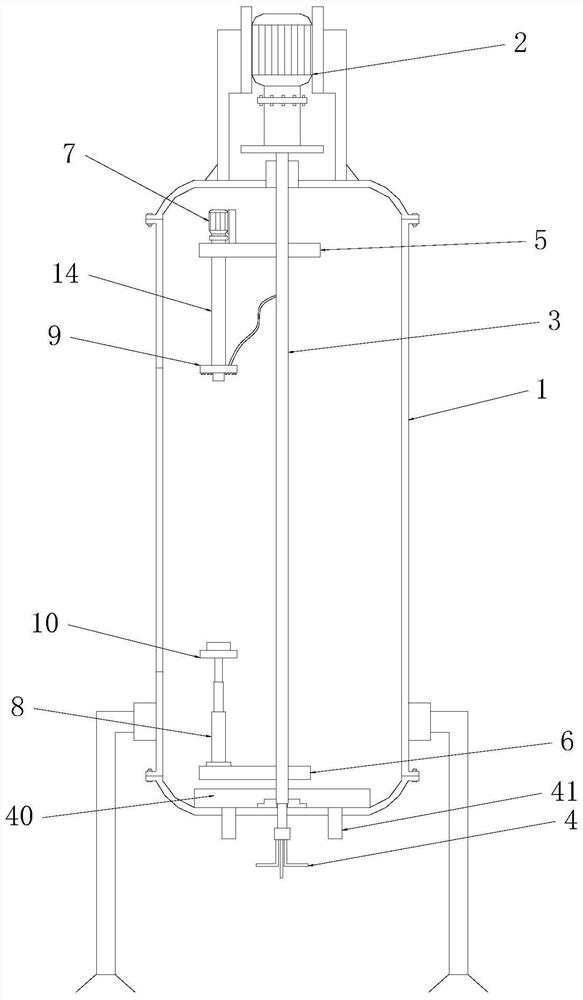

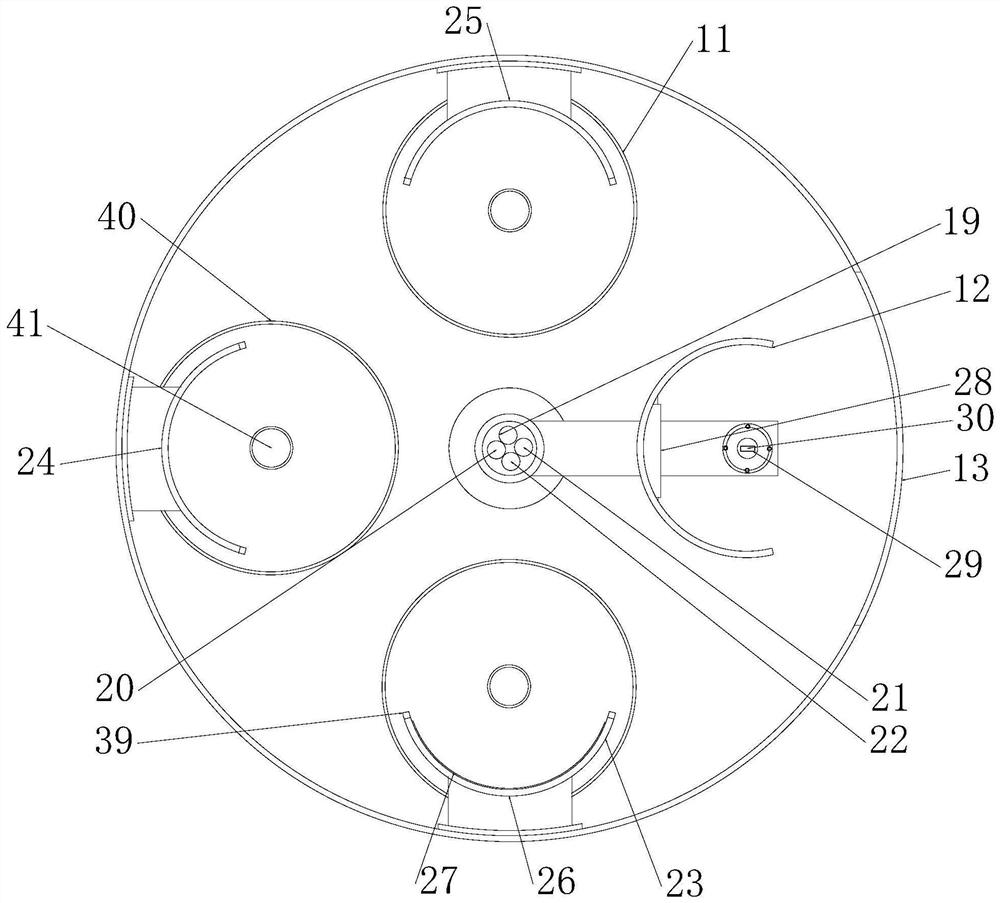

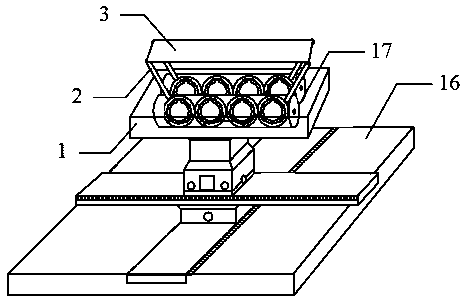

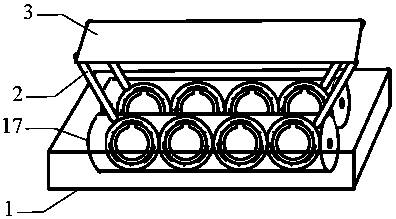

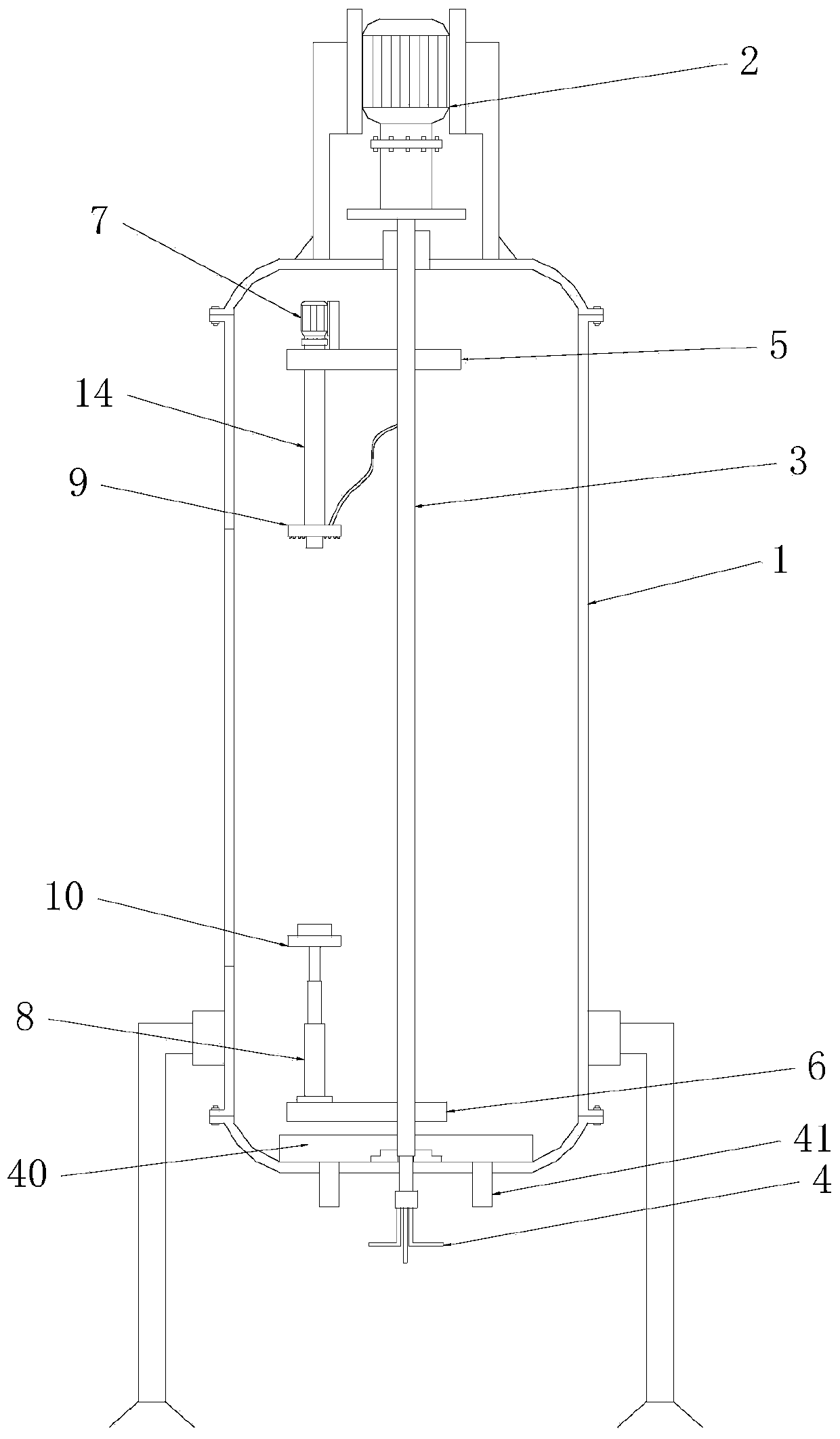

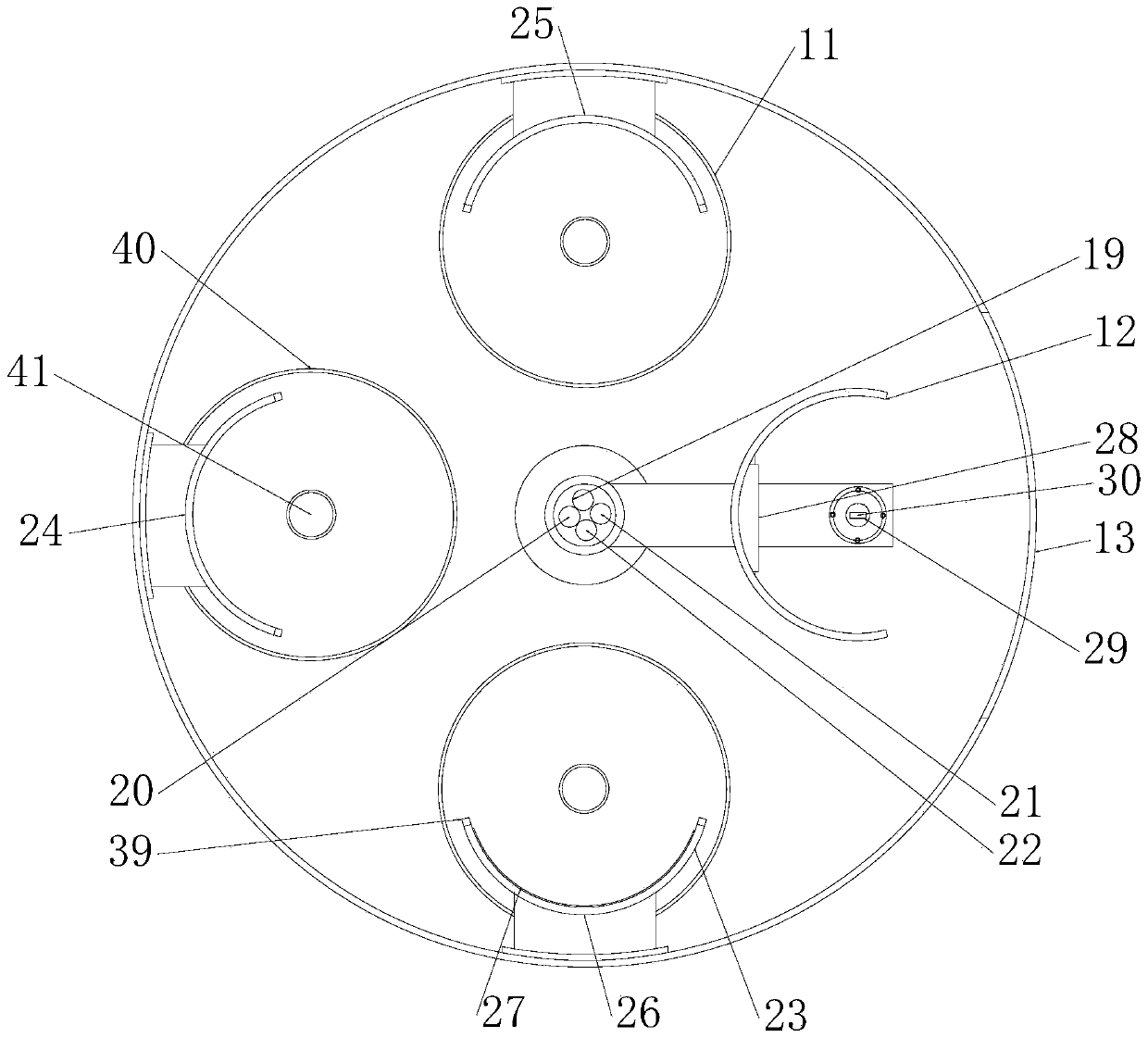

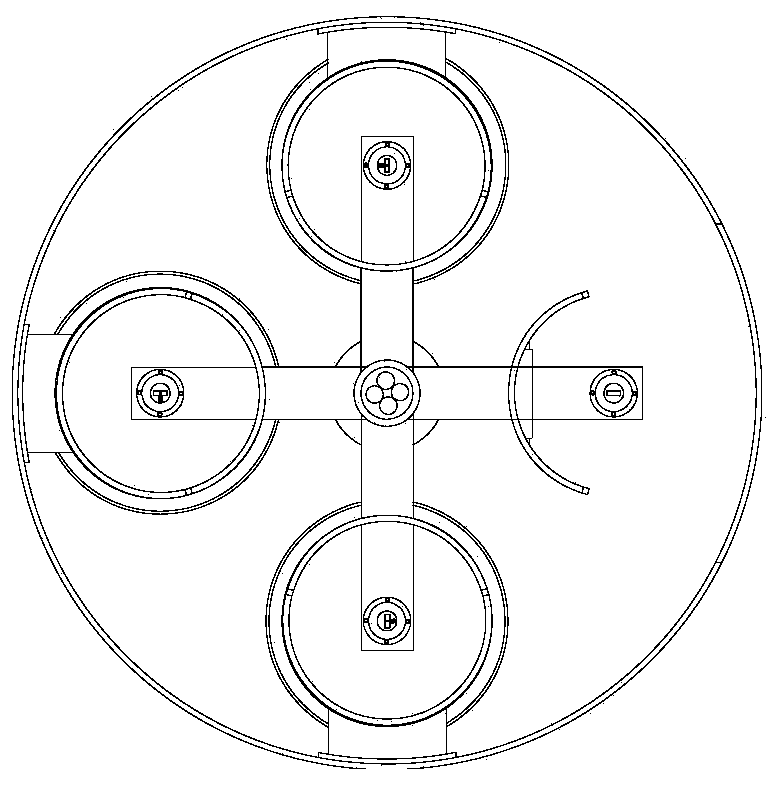

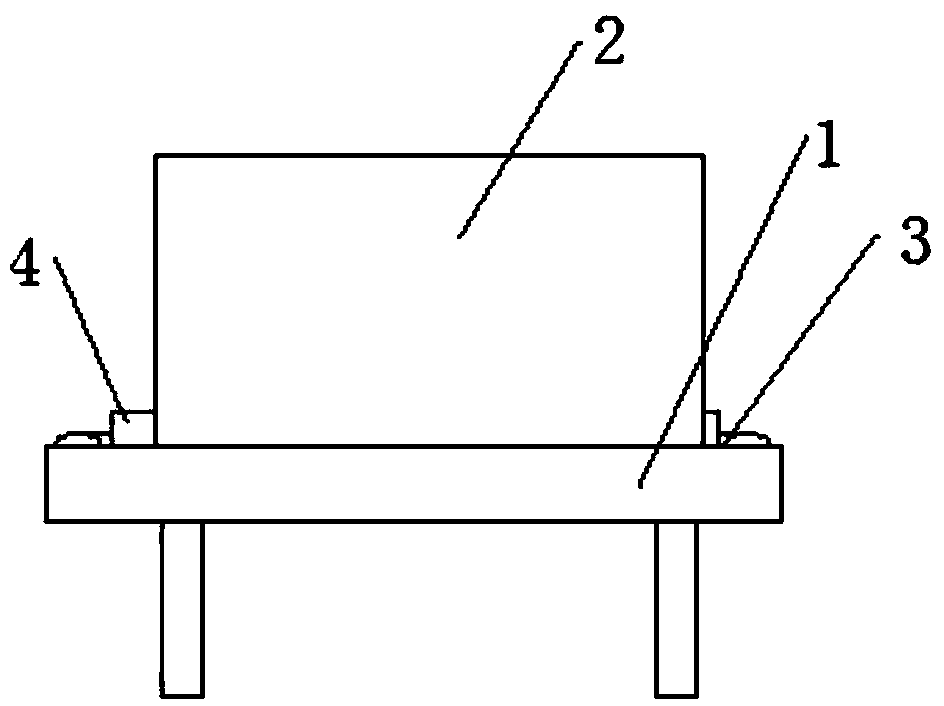

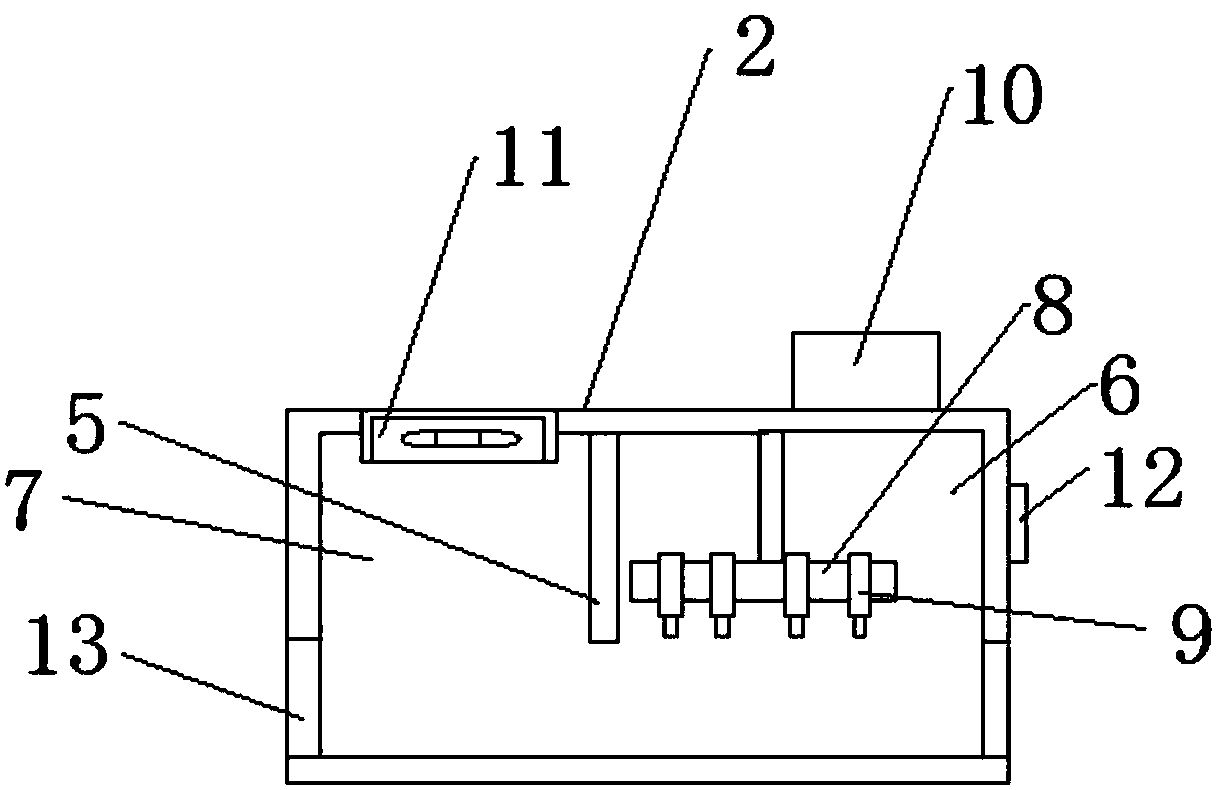

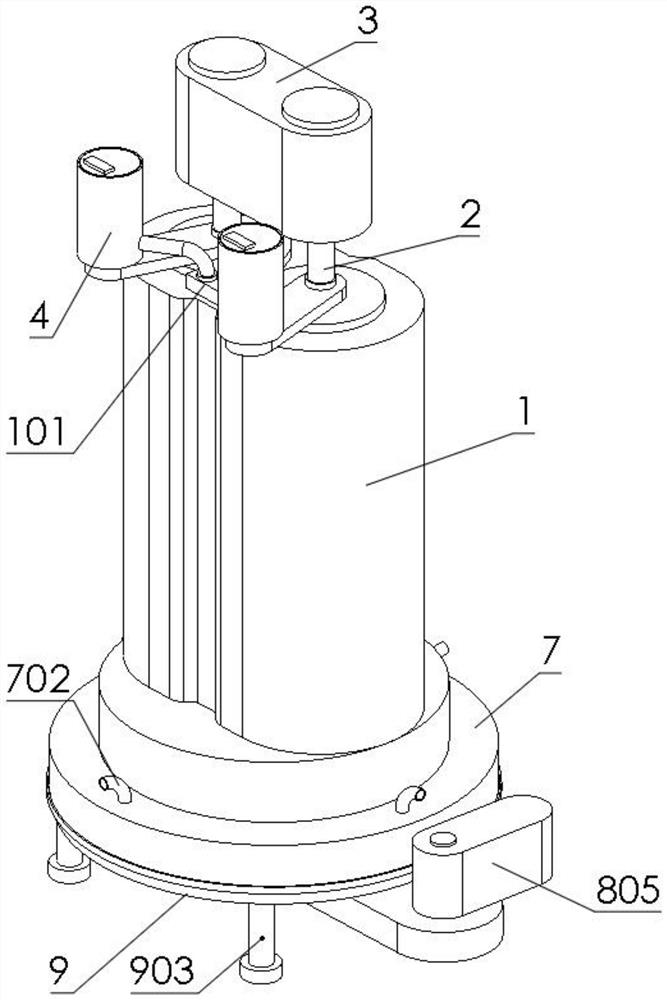

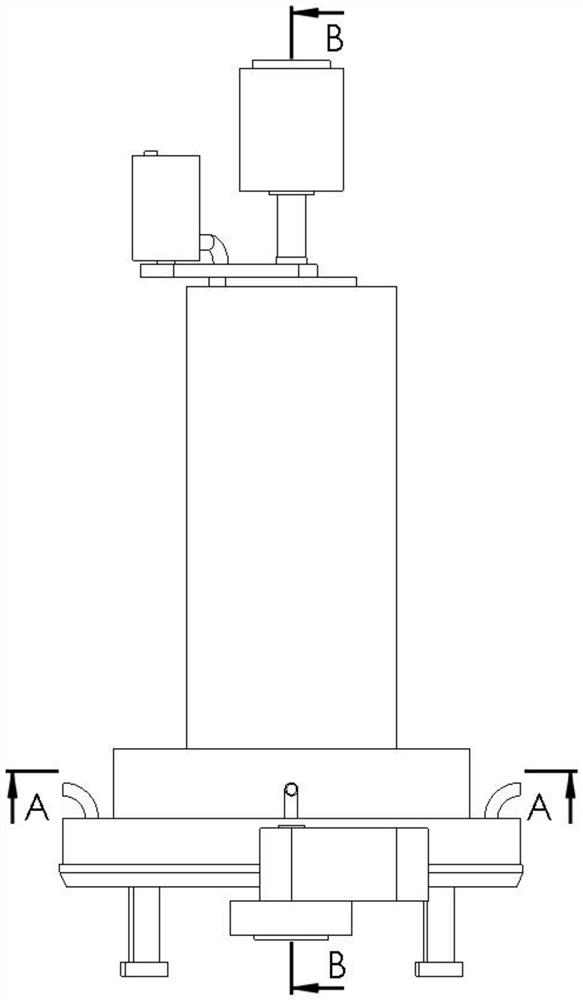

Intelligent standard ice cube processing device

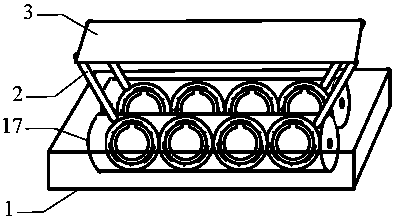

The invention discloses an intelligent standard ice cube processing device. The processing device comprises a vertical kettle, a first motor, a rotating shaft, a pipeline, an upper mounting frame, a lower mounting frame, a second motor, an air cylinder, a first clamping part, a second clamping part, three fixed half cabins and a movable half cabin, wherein a movable door is arranged on the side surface of the vertical kettle; the rotating shaft is a hollow shaft and is vertically and transmissibly mounted in the center of the vertical kettle; the first motor is detachably mounted on the top surface of the vertical kettle and fixedly connected with the top end of the rotating shaft; the pipeline enters from the bottom surface of the vertical kettle and is arranged in an inner cavity of therotating shaft; the upper mounting frame is fixedly arranged at the upper part of the side surface of the rotating shaft; and the lower mounting frame is fixedly arranged at the lower part of the sidesurface of the rotating shaft. The processing device can achieve the purpose of automatic production.

Owner:泰安岱创科技咨询有限公司

Portable coolable mobile power meter body structure

InactiveCN107910907ARapid air coolingExtended service lifeBatteries circuit arrangementsModifications for power electronicsAssistive device/technologyPortable power

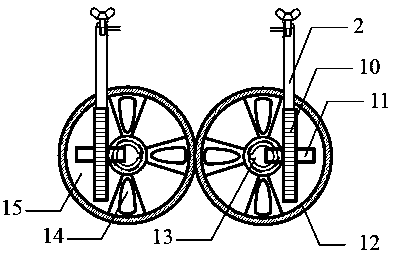

A portable and coolable mobile power watch body structure, belonging to the technical field of auxiliary equipment for use in electronic products, a left baffle is provided on the left side of the mobile power watch body, a left chute is provided on the left baffle, and a left knob is provided in the left chute , there is a right baffle on the right side of the mobile power meter body, a right chute on the right baffle, a right knob inside the right chute, a bottom baffle on the bottom of the mobile power meter body, and a plug on the bottom baffle. There is a fan slot on the body of the mobile power supply between the left and right baffles, and a cooling fan is arranged in the fan slot, and a handle slot is provided on the body of the mobile power supply above the fan slot, and the top of the handle slot Features a handshake surface. The mobile phone is fixed by the left and right knobs, and the cooling fan can quickly cool the mobile phone during charging, which is not only easy to carry, but also can dissipate heat, which is conducive to the normal operation of the internal components of the mobile phone and prolongs the service life of the mobile phone.

Owner:芜湖辉灿电子科技有限公司

A method of using an overhead biochip stage

ActiveCN109108473BRapid Air CoolingEasy to installLaser beam welding apparatusSoftware engineeringBiochip

The invention provides a using method of an overhead type biochip objective table. The objective table is mainly composed of a base station and a rotating device for adjusting chip hack levers. The using method is characterized by comprising the following steps that 1, the specification of the objective table is selected; 2, the chip hack levers are installed; 3, a chip is installed; and the chiphack levers are disassembled after used. The using method has the beneficial effects of being flexible and diversified in operation, convenient, fast and simple, and facilitating the production and processing of the chip or the fixation of a scientific experiment.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of integral and rapid heat dissipation led headlight for vehicle and heat dissipation method

ActiveCN105570784BImprove cooling effectRapid air coolingVehicle headlampsRoad vehiclesEngineeringAirflow

The invention relates to an automotive LED headlamp capable of achieving overall and rapid radiating. The automotive LED headlamp comprises a thermal conductive plastic shell and a metal radiating support, the metal radiating support extends out of the shell and forms radiating fins, and the metal radiating support and the shell are in sealing fit. The part, extending out of the shell, of the metal radiating support is multiple radiating fins alternately distributed in parallel so that heat in the automobile headlamp can be rapidly output to the exterior of the shell of the automobile headlamp through the radiating fins, and airflow generated in the automotive travelling process can conduct radiating on the radiating fins extending out of the shell. In addition, the heat on the metal radiating support is transmitted to the shell through a combination part of the metal radiating support and the shell, and heat is radiated overall and rapidly through the shell; and meanwhile, in the automobile travelling process, the generated airflow conducts rapid air cooling on the overall shell.

Owner:CHANGZHOU TONGBAO PHOTOELECTRIC MFG CO LTD

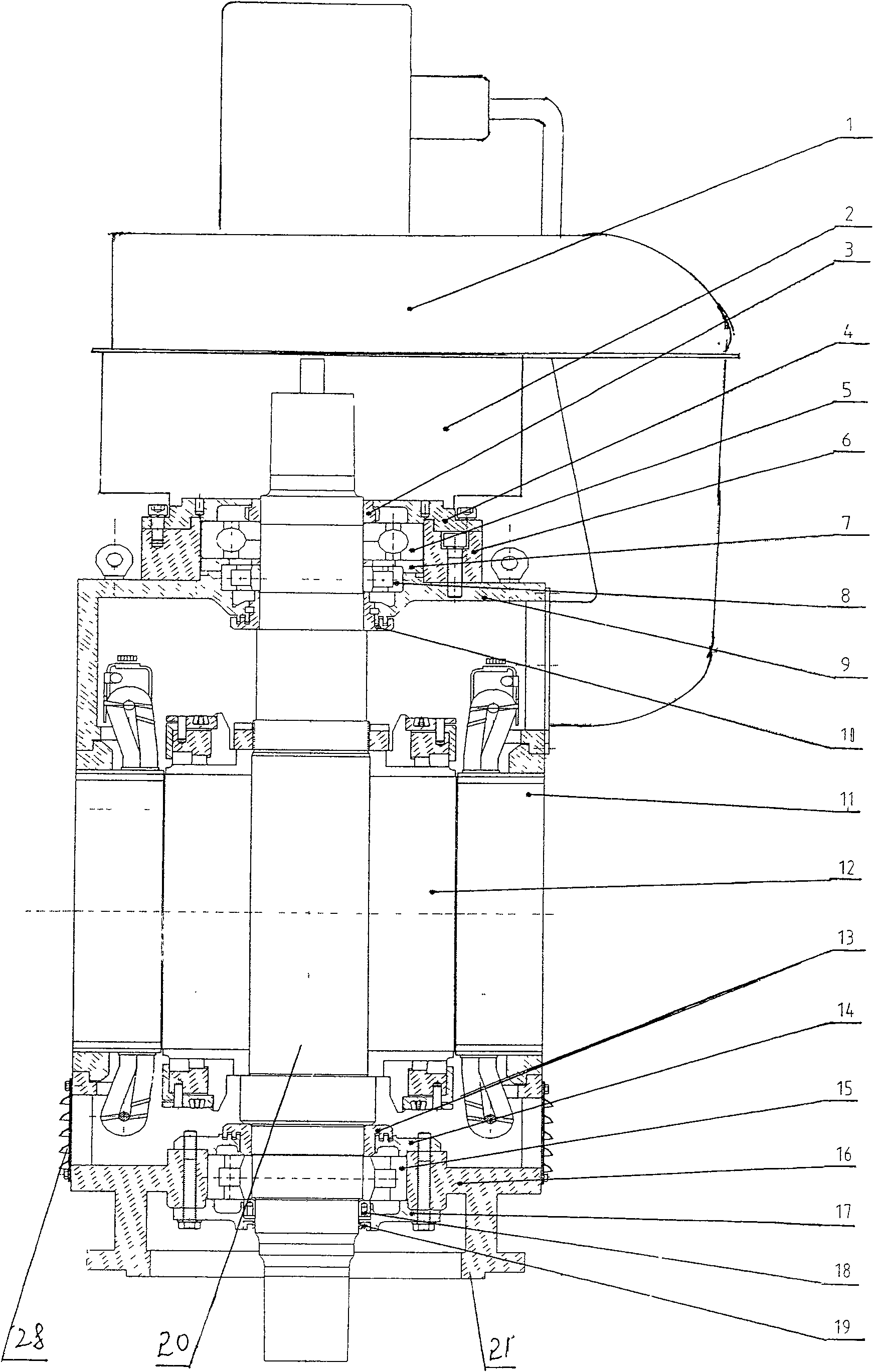

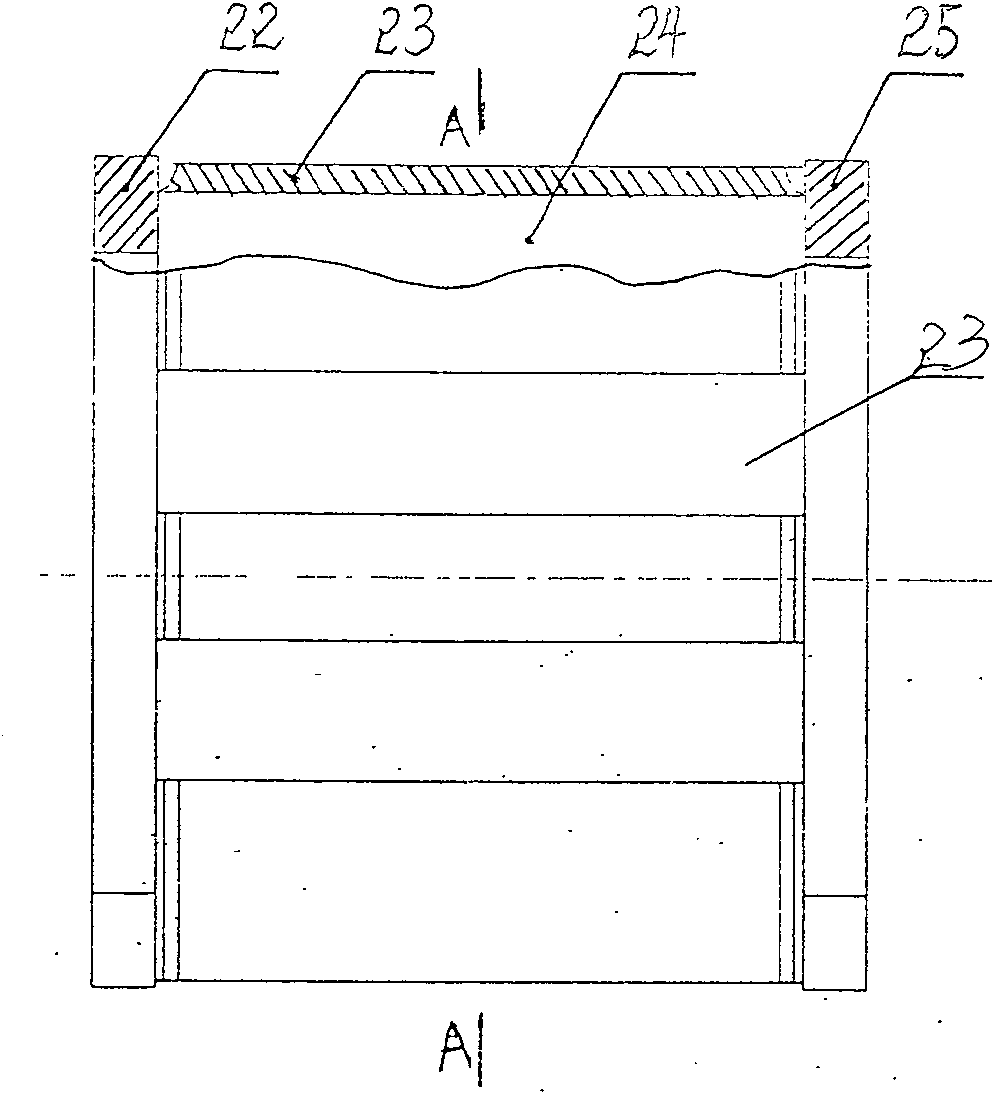

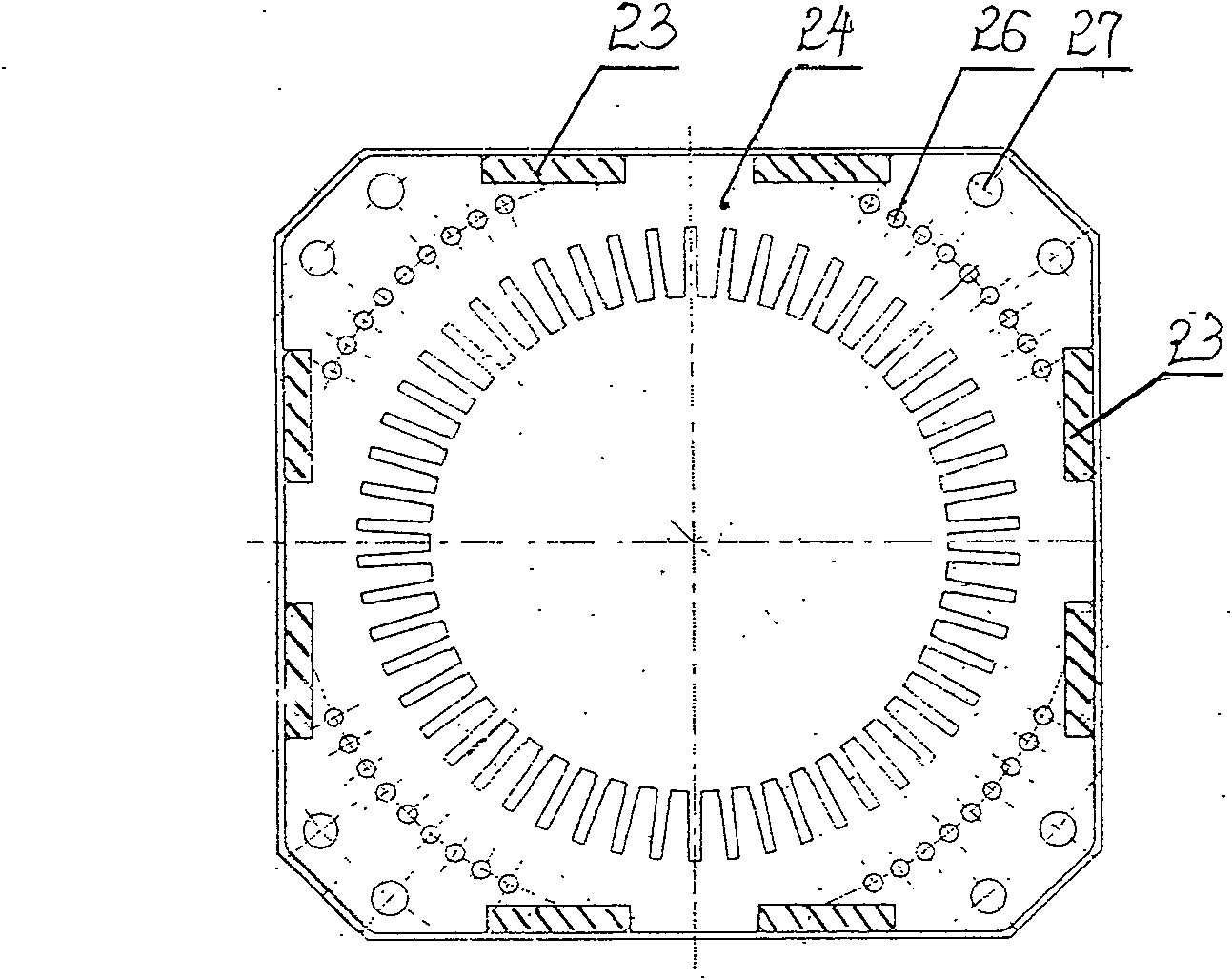

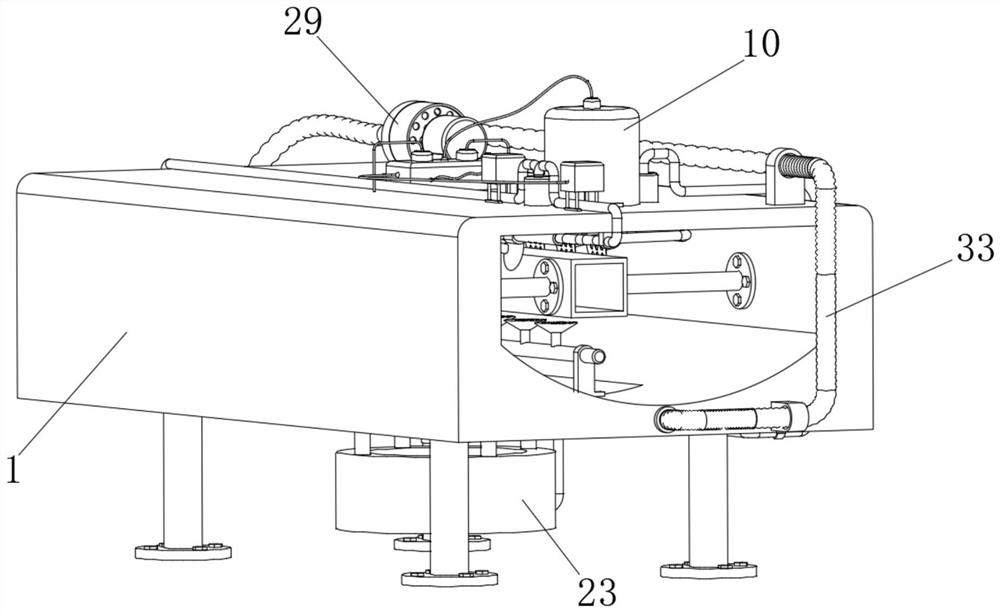

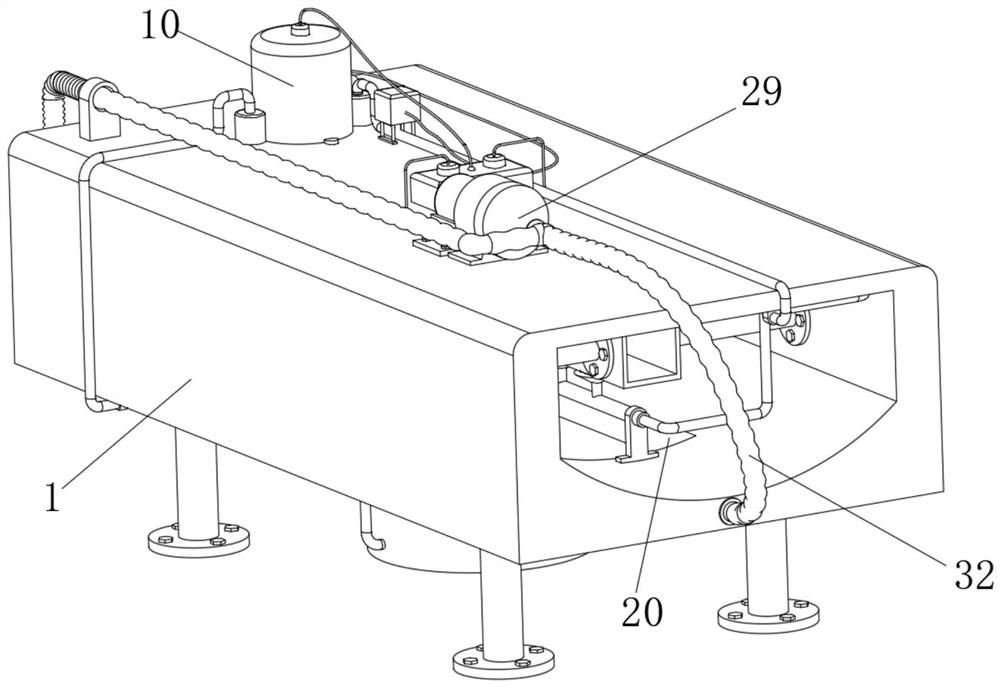

Vertical AC asynchronous topped driven motor

InactiveCN100568673CQuick stopSafe and reliable operationMagnetic circuit stationary partsMechanical energy handlingFailure rateConstant power

The invention relates to an asynchronous motor, in particular to a vertical AC asynchronous top drive motor. The problem that the domestic top drive motor cannot be manufactured in the prior art is solved. Including the stator assembly, the upper end cover and the lower end cover installed at both ends, and the rotor assembly in the middle of the stator assembly. The rotating shaft of the rotor assembly is matched with the upper end cover and the lower end cover through the non-drive end bearing and the drive end bearing respectively. The shaft end of the non-drive end of the rotating shaft is The upper end cover is stretched out and a four-point contact ball bearing is also sleeved on the non-drive end of the rotating shaft. The vertical AC asynchronous top drive motor of the present invention has a novel and reasonable structural design, strong overload capacity, wide constant power area, low failure rate, safe and reliable use, and fully meets the use requirements of the top drive device for oilfield mining machinery. Ended the history of my country's top drive motors relying on imports.

Owner:CRRC YONGJI ELECTRIC CO LTD

An intelligent cooling device for forming aluminum profiles

The invention relates to the technical field of cooling devices for forming aluminum profiles, and discloses an intelligent cooling device for forming aluminum profiles. Through cooling pumps and other settings, the rapid cooling of the casting shaping tube and the upper and lower parts of the formed high-temperature aluminum profiles inside is realized, and the improvement of the temperature is improved. The cooling effect per unit time, through the temperature sensor and other settings, realizes intelligent cooling according to the upper and lower temperatures of the casting shaped tube, avoiding constant cooling when the temperature is low, thereby avoiding the waste of resources such as cooling liquid, through the collection tank and collection The arrangement of the pipes and the like enables the coolant to be recovered centrally after being sprayed out by the porous nozzle, enters the collection box below through the collection pipe, and then is sucked into the cooling pump by the water inlet pipe, thereby realizing the circulation of the coolant and avoiding the cooling of the coolant. After high-pressure spraying, the lack of a recovery mechanism causes waste. The air outlet pipe and other settings ensure that the coolant is always kept at a low temperature before cooling, and it is beneficial to the collection of the coolant.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

Device and method for cleaning and disinfecting waste beer bottles

InactiveCN108014350ARapid air coolingReasonable designDrying gas arrangementsLavatory sanitoryFixed frameEngineering

The invention discloses a device and method for cleaning and disinfecting waste beer bottles. The device includes a working table, a disinfection room and a conveyor belt, a separating plate divides the disinfection room into a drying room and a cooling room, a vertical downward inverted T-shaped fixed frame is welded to the top end of the inner wall of the drying room, a plurality of inclined downward drying nozzles are mounted at equal distances on the inverted T-shaped fixed frame, an air heater is fixed on upper top end outside the disinfection room, a cooling fan is embedded in the uppertop end of the cooling room, partition nets are fixedly installed at both sides of the conveyor belt on the worktable, and a plurality of limiting blocks are fixedly arranged at equal distances on thesurface of the conveyor belt. The device has a reasonable and ingenious design, and high-temperature gas generated by the air heater is injected into the beer bottles on the conveyor belt to disinfect the beer bottles at a high temperature, so that disinfection is even and thorough; meanwhile, multiple groups of the drying nozzles are used simultaneously for drying and disinfecting the beer bottles, thereby greatly improving the rate of drying and disinfection.

Owner:安徽荣泰玻璃制品有限公司

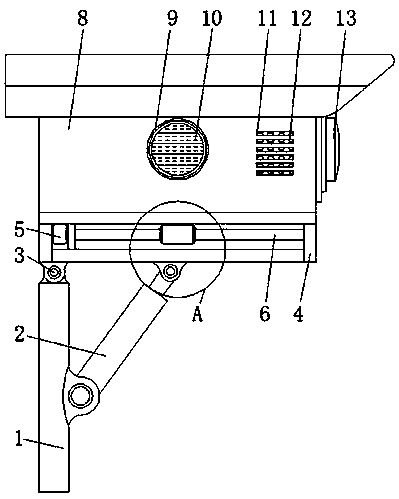

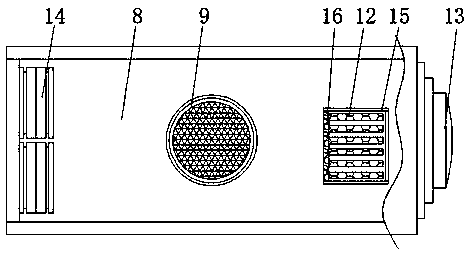

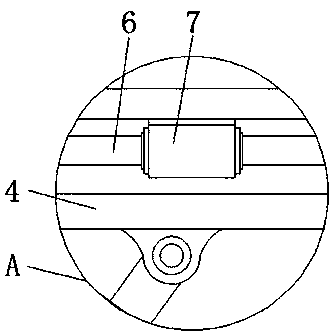

Gun-shaped camera with moisture-proof and heat-dissipation functions

PendingCN110971808AEfficient use ofImprove adsorption capacityTelevision system detailsColor television detailsActivated carbonElectric machinery

The invention discloses a gun-shaped camera with moisture-proof and heat-dissipation functions. The camera comprises a supporting rod, an adjusting hydraulic oil cylinder, a connecting pin, a fixing frame, a micro linear lead screw motor, a lead screw, a connecting sleeve column, a camera shell, a notch, a fixing groove box, a through hole, dust collection cotton, a camera head, a cooling fan, a housing and an activated carbon plate. The connecting pin penetrates through the upper part of the supporting rod. The adjusting hydraulic oil cylinder is installed on one side of the supporting rod. The fixing frame is installed above the adjusting hydraulic oil cylinder. A miniature linear lead screw motor is arranged in the fixing frame. The lead screw is installed on one side of the miniature linear lead screw motor. The connecting sleeve column is installed in the middle of the lead screw, and a camera shell is installed above the connecting sleeve column. Damp gas in the camera shell canbe effectively adsorbed through the drying agent, moisture carried by the gas can be effectively reduced, dryness of the gas is guaranteed, and the damp gas is prevented from corroding the assembly.

Owner:深圳市吉科源电子技术有限公司

Automotive LED headlamp capable of conducting forced cooling during automobile motion

ActiveCN105570785AImprove cooling effectSimple structurePoint-like light sourceLighting heating/cooling arrangementsEngineeringHeadlamp

The invention relates to an automotive LED headlamp capable of conducting forced cooling during automobile motion. The automotive LED headlamp comprises a shell and a transparent cover, a sealing cavity is formed by the shell and the transparent cover, and an LED assembly is arranged at the position, on the front side face of the shell, in the sealing cavity and arranged on a metal radiating support; and the metal radiating support extends out the shell and forms radiating fins, and the metal radiating support and the shell are in sealing fit so that heat in the automobile headlamp can be rapidly output to the exterior of the shell of the automobile headlamp through the radiating fins, and airflow generated in the automotive travelling process can conduct radiating on the radiating fins extending out of the shell. In addition, heat on the metal radiating support is transmitted to the shell through a combination part of the metal radiating support and the shell, and heat is rapidly radiated overall outwards through the shell; and meanwhile, in the automobile travelling process, the generated airflow conducts rapid air cooling on the overall shell.

Owner:CHANGZHOU TONGBAO PHOTOELECTRIC MFG CO LTD

Environment-friendly coating cooling and crushing device

InactiveCN112547250AAffect qualityRapid air coolingGrain treatmentsShaping pressCooling effectEngineering

The invention discloses an environment-friendly coating cooling and crushing device which comprises a charging barrel internally provided with a screw rod and an extrusion driving mechanism used for providing power for the screw rod through a transmission shaft. The charging barrel is vertically arranged below the extrusion driving mechanism, and a feeding port is formed in the upper portion of the charging barrel; a feeder is arranged at one side of the upper part of the charging barrel and is connected with the feeding port; an extruding disc is arranged at an outlet in the bottom of the charging barrel, and a cutting device is arranged on the extruding disc; a crushing device is arranged below the cutting device, and a cooling device is arranged in the crushing device; a discharging device is arranged below the crushing device; the crushing device comprises a crushing conical barrel arranged under the cutting device, a crushing edge is arranged at the lower part of the outer wall ofthe crushing conical barrel, and a bulge is arranged on the crushing edge; and a material falling opening is formed in one side below the material crushing edge. By means of the environment-friendlycoating cooling and crushing device, the rapid extrusion cooling effect can be achieved through a cutting mechanism, and meanwhile powder coating extruded sheets are efficiently crushed and cooled.

Owner:HUNAN LIANXIN SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com