A kind of integral and rapid heat dissipation led headlight for vehicle and heat dissipation method

A heat dissipation method and headlight technology, which is applied in the field of car lights, can solve the problems of high failure rate of cooling fans, difficult heat generation, high production cost, etc., and achieve the effects of ensuring normal operation and service life, improving heat dissipation effect, and solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

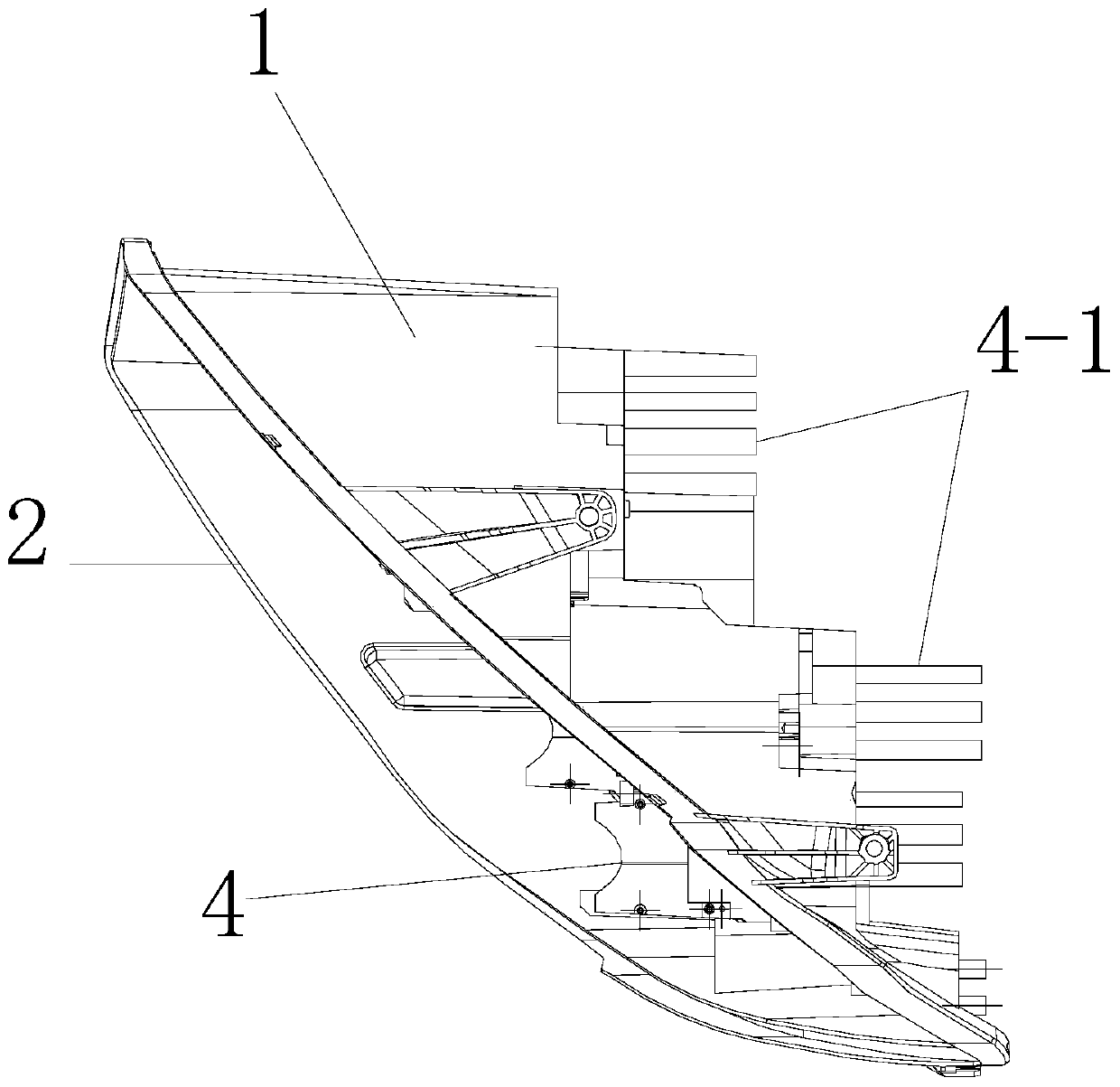

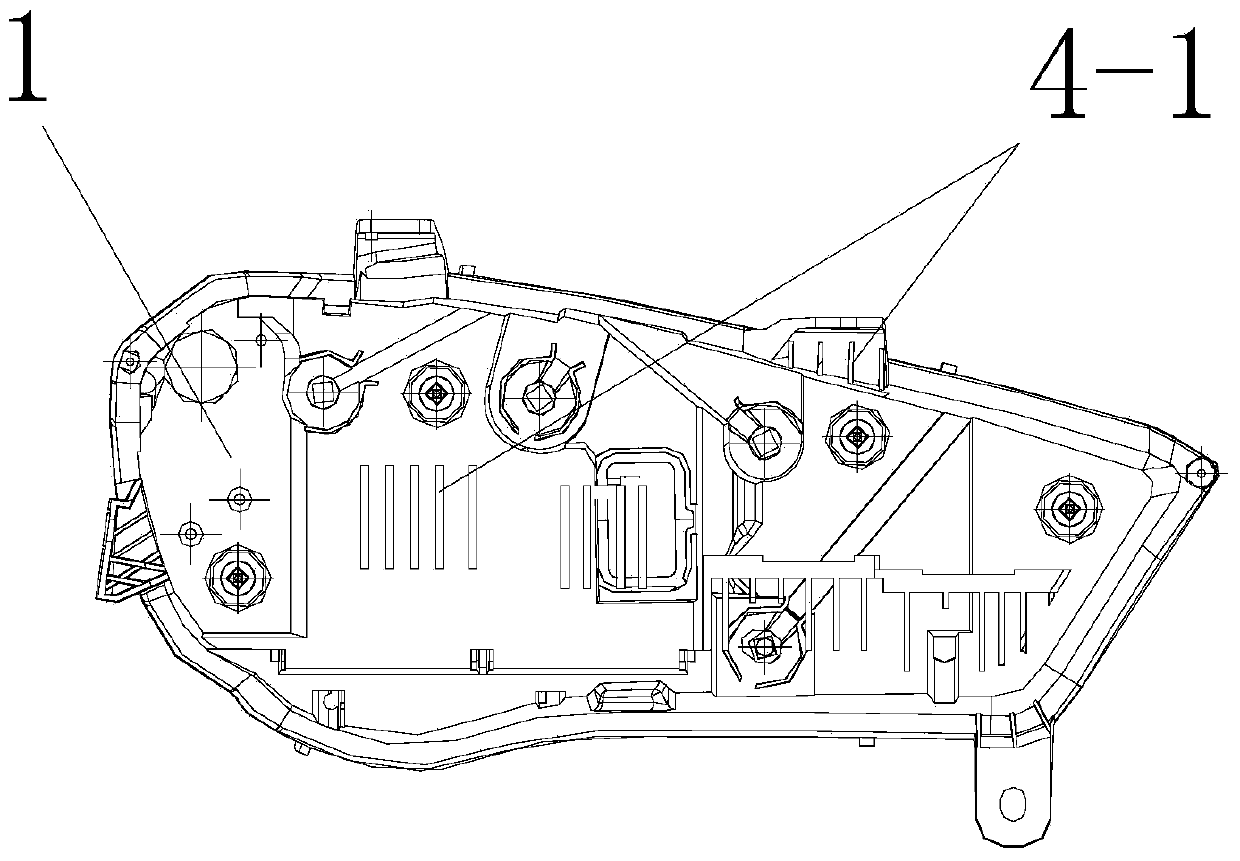

[0029] See Figures 1 to 2 ,or Figure 3-7 , the rapid heat dissipation LED headlamp for vehicle of the present embodiment comprises: a heat conduction housing 1, a transparent cover 2 sealed and arranged on the front side of the housing 1, the housing 1 and the transparent cover 2 form a sealed cavity, and The sealed cavity is provided with an LED assembly and a metal cooling frame 4, the LED assembly 3 is arranged on the metal cooling frame 4, and the rear end, and / or bottom, and / or top of the metal cooling frame 4 extends out of the housing 1, The metal cooling frame 4 is tightly fitted with the housing 1 .

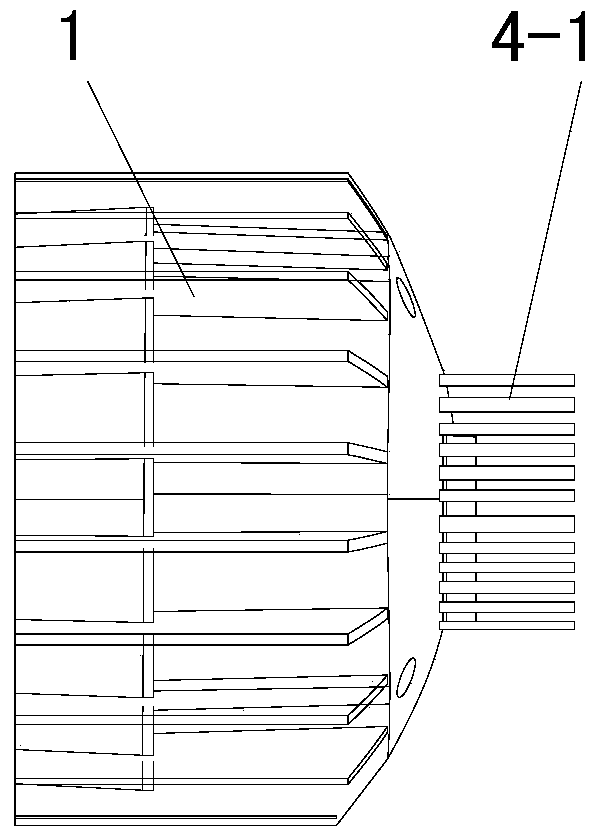

[0030] The metal cooling frame includes: a front panel for setting the LED assembly 3, and the cooling fins 4-1 connected to the rear side of the front panel; each cooling fin 4-1 passes through the housing 1, and The middle part of each cooling fin 4-1 is injection molded together with the housing 1 at one time.

[0031] When the vehicle headlight is installed on t...

Embodiment 2

[0039] The production method of the above-mentioned LED headlights for vehicles includes: fixing the metal heat dissipation frame 4 in the mold, extending the part of the housing 1 required by each heat dissipation fin 4-1, and adopting a mold with a melting point higher than the injection molding temperature. The material or sheet fills the gaps between adjacent heat dissipation fins 4-1, and then performs mold clamping, filling, pressure maintaining, cooling and demoulding in sequence to remove the material or sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com