Overhead biological chip objective table

A biochip and stage technology, applied in the field of stage, can solve the problem that the fixture stage cannot meet the processing needs, and achieve the effect of simple structure, convenient processing and production, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

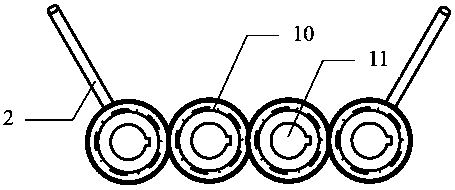

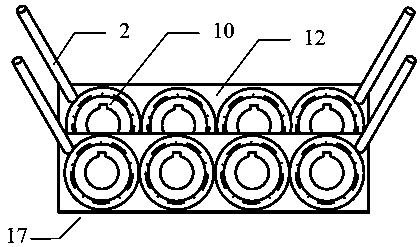

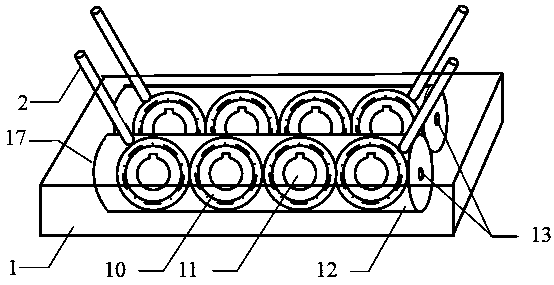

[0024] see figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11. The two columnar gears 12 are elongated columns, and the surface of the column is processed with teeth parallel to the column axis, that is, the gear shaft 13. The two columnar gears 12 are engaged with each other and installed horizontally inside the abutment 1. Inside the column gear 12 is a hollow gear with a gear hub 14 and a cavity 15 . On one side of the gear shaft 13, a row of four pinion gears 10 vertically arranged on the same space plane is installed. The space plane of the vertically arranged pinion gears 10 is parallel to the gear shaft 13 of the columnar gear 12, and two columnar gears are vertically arranged. The gears 12 mesh with each other on a horizontally placed horizontal plane. 8 small gears 10 are arranged in two rows, and one row of 4 small gears 10 is packed into a cylindrical gear 12 inside. The four chip holder rods 2 are evenly and symmetrically distributed and...

specific Embodiment 2

[0025] see Image 6 , Figure 10 . The two columnar gears 12 are elongated columns, and the surface of the column is processed with teeth parallel to the column axis, that is, the gear shaft 13. The two columnar gears 12 are engaged with each other and installed horizontally inside the abutment 1. Inside the column gear 12 is a hollow gear with a gear hub 14 and a cavity 15 . On one side of the gear shaft 13, a row of two pinion gears 10 vertically arranged on the same space plane is installed. The space plane where the vertically arranged pinion gears 10 are located is parallel to the gear shaft 13 of the columnar gear 12, and the two columnar gears are perpendicular to each other. The gears 12 mesh with each other on a horizontally placed horizontal plane. 4 small gears 10 are arranged in two rows, and 2 small gears 10 in a row are packed into a cylindrical gear 12 inside. The four chip holder rods 2 are evenly and symmetrically distributed and installed on the gear apex...

specific Embodiment 3

[0026] see figure 2 , image 3 , Figure 4 , Figure 5 . The four four-way balls 6 are arranged in the same 2 rows of even numbers vertically and horizontally, and there are two four-way balls 6 in a row. The four-way ball 6 is a sphere of the same radius that is cooperating with each other. On the vertical longitude direction surface of the four-way ball 6 spheres, the top and bottom balls of the four-way ball 6 are processed in a symmetrical cross, and the planes of the spatial direction are perpendicular to each other. A circle of longitudinal interlocking tooth lines 7 and a circle of transverse interlocking tooth lines 8. The processing of longitudinal interlocking teeth 7 and a circle of transverse interlocking teeth 8 is to ensure that when four four-way balls 6 are initially engaged together, the vertical axes of the upper and lower ball points of each four-way ball 6 remain vertical to the same horizontal plane, and the four-way balls The vertices in the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com