Automotive LED headlamp capable of conducting forced cooling during automobile motion

A technology for headlights and LED components, which is applied to motor vehicles, road vehicles, and components of lighting devices, etc., can solve the problems of high overall sealing requirements, difficult heat, and difficult sealing of headlights, so as to ensure normal performance. Work and service life, solve the sealing problem, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

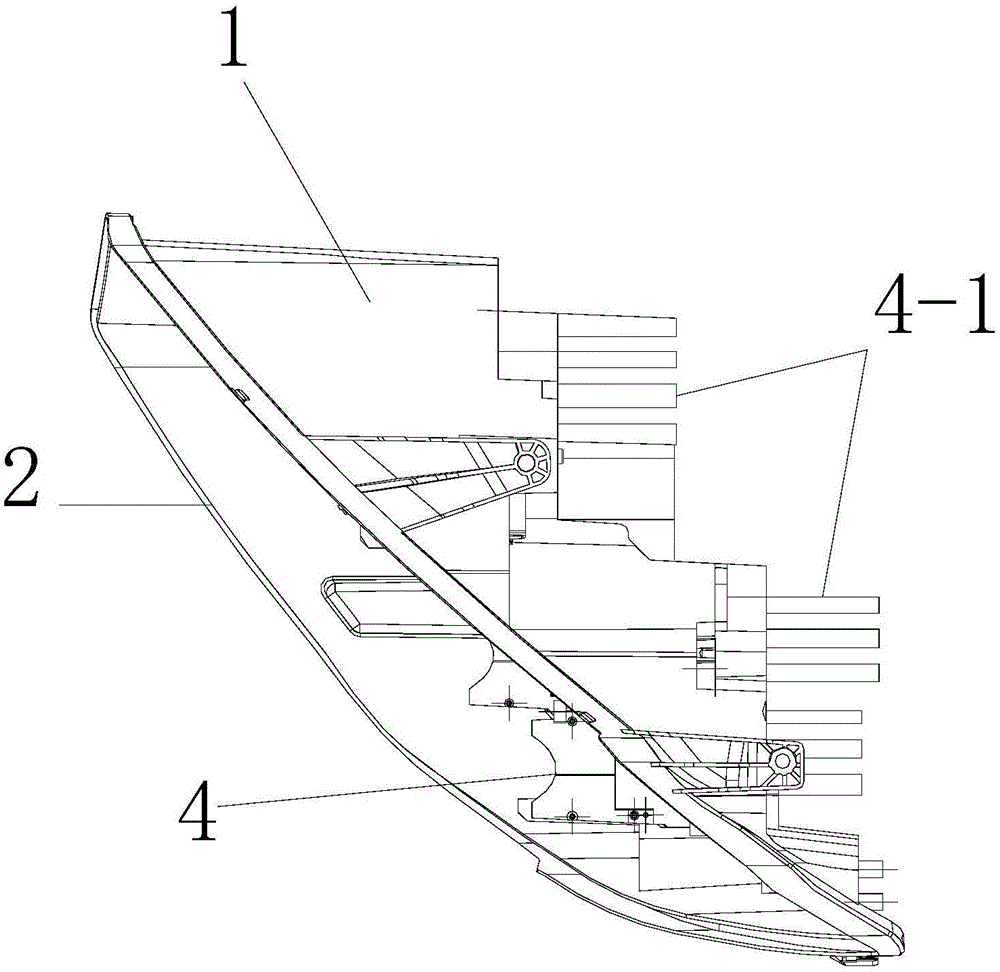

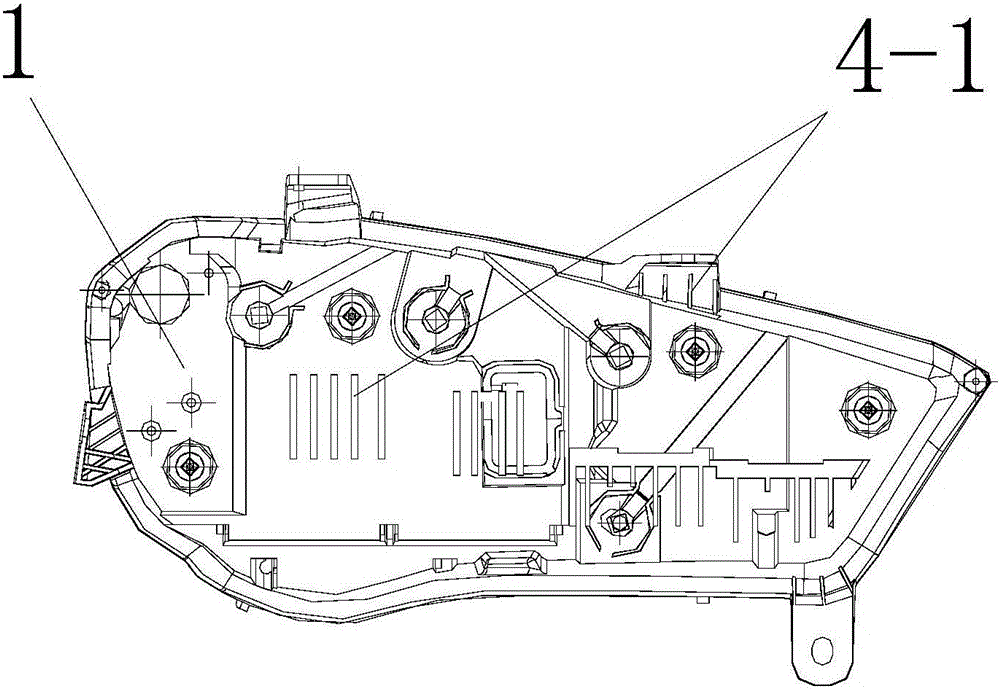

[0029] see Figure 1 to 2 ,or Figure 3-7 , The vehicle LED headlight of this embodiment includes: a heat-conducting shell 1, a transparent cover 2 sealed and arranged on the front side of the shell 1, and the shell 1 and the transparent cover 2 form a sealed cavity, in the sealed cavity An LED assembly and a metal heat dissipation frame 4 are provided. The LED assembly 3 is arranged on the metal heat dissipation frame 4. The rear end, and / or bottom, and / or top of the metal heat dissipation frame 4 extend out of the housing 1, and the metal heat dissipation frame 4 With the housing 1 hermetically fit.

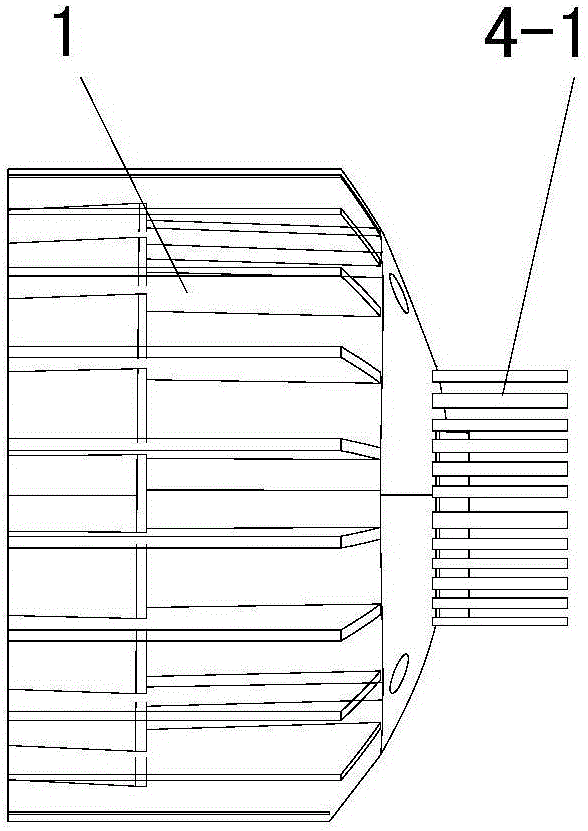

[0030] The metal heat dissipation frame includes: a front panel for arranging the LED assembly 3, and the heat dissipation fins 4-1 connected to the rear side of the front panel; each heat dissipation fin 4-1 passes through the housing 1, and The middle part of each heat dissipation fin 4-1 and the casing 1 are injection-molded at one time.

[0031] When the vehicle headlight is i...

Embodiment 2

[0039] The production method of the above-mentioned vehicle LED headlight includes: fixing the metal heat dissipation frame 4 in a mold, and adopting a melting point higher than the injection temperature for the part of each heat dissipation fin 4-1 that needs to extend out of the housing 1 Fill up the gaps between adjacent radiating fins 4-1 with the materials or sheets, and then perform mold clamping, filling, pressure holding, cooling and demolding in sequence to remove the materials or sheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com